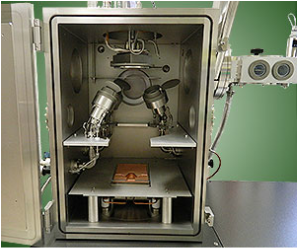

HV 박스 챔버는 최대 6 인치 직경의 기판을 위한 터보 펌프 진공로드 락과 모든 스퍼터링 및 히터 기능을 수행하고 e- beam 작동을 위한 Inficon 증착 컨트롤러와 수활하게 인터페이싱되는 LabView 기반 컴퓨터 컨트롤 시스템을 갖추고 있습니다. 6 pocket, 쉴드된 15cc 로터리 포켓 전자빔 소스, 하나의 2 ", 두 개의 3" 마그네트론 스퍼터 소스 (틸트 포함), azimuthal rotation, Z 모션 및 RF 바이어스를 갖춘 850°C 기판 히터를 특징으로 합니다.

vacuum load-lock for substrates up to 6" diameter and

Labview based computer control system which handles

all sputtering and heater functions and interfaces seamlessly

with the Inficon Deposition Controller for e-beam operations.

with shielding, (1) 2" and (2) 3"magnetron sputter sources with tilt

and an 850°C substrate heater with azimuthal rotation, Z motion and RF bias.

General Information

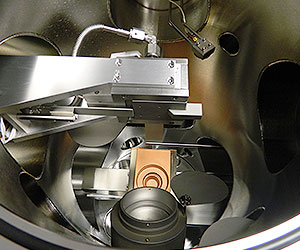

AJA International ATC-M Series Multi-Technique Systems are versatile tools that combine various thin film deposition, ion milling and analytical operations in a single chamber (Hybrid Systems) or in multiple chambers (Multi-Chamber Systems) to allow the in-situ transfer of substrates from process to process without breaking vacuum.

These systems can be built in HV or UHV configurations, and in either cylindrical, box or machined chambers styles.

Multi-Techniques employed include:

- Magnetron Sputtering

- E-Beam Evaporation

- Thermal Evaporation

- Ion Milling

- Ion Beam Deposition

- Pulsed Laser Deposition

- Ellipsometry

- Rapid Thermal Anneal

- Oxygenation and Nitridization

- XPS/AUGER/LEED Analysis

- MBE, RHEED, MOS, SIMS, RIBE