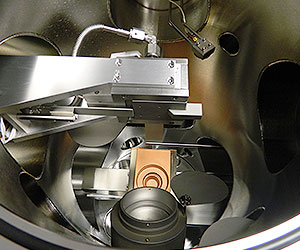

2개의 하이브리드 프로세스 챔버가 결합되어 있으며, 각각 e-beam과 thermal evaporation, 공 초점 마그네트론 스퍼터링 (confocal magnetron sputtering), 360도 틸트가 있는 이온 빔 에칭 (ion beam etching) 및 수냉식 기판 홀더가 특징입니다. 더욱이, ATC-HY Multi-Chamber Hybrid Deposition Tool의 셋째 공정 챔버는 포스트 어닐링 (post anneal), 산소화 (oxygenation) 및 애싱 (ashing) 기능을 갖추고 있습니다. 모두단면 절연 (sectional isolation) 및 통합 로드 락 (load-lock), 글러브 박스 호환성이 있는 UHV 자기 이송 튜브 (UHV magnetic transfer tube)를 통해 연결됩니다.

General Information

AJA International ATC-M Series Multi-Technique Systems are versatile tools that combine various thin film deposition, ion milling and analytical operations in a single chamber (Hybrid Systems) or in multiple chambers (Multi-Chamber Systems) to allow the in-situ transfer of substrates from process to process without breaking vacuum.

These systems can be built in HV or UHV configurations, and in either cylindrical, box or machined chambers styles.

Multi-Techniques employed include:

- Magnetron Sputtering

- E-Beam Evaporation

- Thermal Evaporation

- Ion Milling

- Ion Beam Deposition

- Pulsed Laser Deposition

- Ellipsometry

- Rapid Thermal Anneal

- Oxygenation and Nitridization

- XPS/AUGER/LEED Analysis

- MBE, RHEED, MOS, SIMS, RIBE

The ATC-HY Multi-Chamber Hybrid Deposition Tool combines two Hybrid Process Chambers, each featuring e-beam and thermal evaporation, confocal magnetron sputtering, ion beam etching with a 360 degree tilt, and a water-cooled substrate holder. In addition, a third process chamber features post anneal, oxygenation and ashing capability. All are connected via a UHV magnetic transfer tube with sectional isolation, integral load-lock and glovebox compatibility.