Different Shapes of Sputtering Targets

(주)연진에스텍은 Planar (flat) Target과 Rotary (cylindrical) Target, Circular Target 및 Ring Target 등 대부분의 증착 공정에 부합하는 다양한 형태의 스퍼터링 타겟을 제공하며, 타겟 크기의 커스터마이즈가 가능합니다.

당사의 Ytterbium Planar Target은 99.9%~99.99%(3N~4N) 순도의 이터븀 금속으로 제작되어 정밀 박막 증착에 최적화되어 있습니다. 50~200mm의 직경에 3~10mm의 두께로 제공되며, 열 안정성 향상을 위해 구리 또는 몰리브덴 백킹 플레이트와 본딩해드릴 수 있습니다. 50µm 미만의 미세 입자 구조와 95% 이상의 이론값에 달하는 높은 밀도를 갖도록 설계되어 입자 생성을 최소화하고 박막 균일성이 보장됩니다. 각 타겟은 산화 방지를 위해 아르곤 가스로 채워진 진공 포장재에 밀봉되어 배송됩니다. 공급사는 ICP-MS impurity analysis 및 XRD crystallographic verification을 포함한 상세한 품질 인증서를 제공합니다. 최적화를 위해 RF power와 가스 압력과 같은 스퍼터링 파라미터에 대해 지원하며, 표준품 주문 시 3~4주 소요됩니다.

Ytterbium Planar Target Description:

SAM’s Ytterbium Planar Targets are made from 99.9% to 99.99% (3N–4N) pure ytterbium metal, tailored for precision thin-film deposition. Available in standard diameters ranging from 50 to 200 mm and thicknesses from 3 to 10 mm, these targets can be bonded to Cu or Mo backing plates to enhance thermal stability. Designed with a fine-grained microstructure (<50 µm) and high density (>95% theoretical value), they minimize particle generation, ensuring film uniformity. Each target is vacuum-sealed in argon-filled packaging to prevent oxidation. SAM also provides detailed quality certifications, including ICP-MS impurity analysis and XRD crystallographic verification. For optimization, SAM offers support with sputtering parameters like RF power and gas pressure, with global shipping times of 3–4 weeks for standard orders.

Ytterbium Planar Target Specifications:

- Purity: 99.9%

- Density: 6.90 g/cm³

- Melting Point: 824°C

- Boiling Point: 1196°C

- Shape: Rectangular or customized upon request

- Size: Customizable to requirements

Note: For specific requirements, please reach out to SAM for more detailed inquiries.

Applications of Ytterbium Planar Targets:

- Fiber Lasers & Amplifiers: Ytterbium-doped films for high-power fiber lasers (e.g., Yb:YAG) in industries such as telecommunications and cutting.

- Atomic Clocks: Used in the production of ultra-precise optical lattice clocks.

- Solar Cells: Ytterbium-based coatings to improve photon conversion in perovskite solar cells.

- Nuclear Medicine: Coatings for Yb-169 isotope, used in portable gamma-ray sources.

- Quantum Research: Yb³⁺-doped materials for quantum memory and entanglement experiments.

Ytterbium Planar Packaging Information:

SAM ensures customized packaging for optimal protection during transportation, with options including cartons, wooden crates, or tailored packaging solutions. Small products are securely placed in PP boxes, while larger items are housed in custom wooden crates.

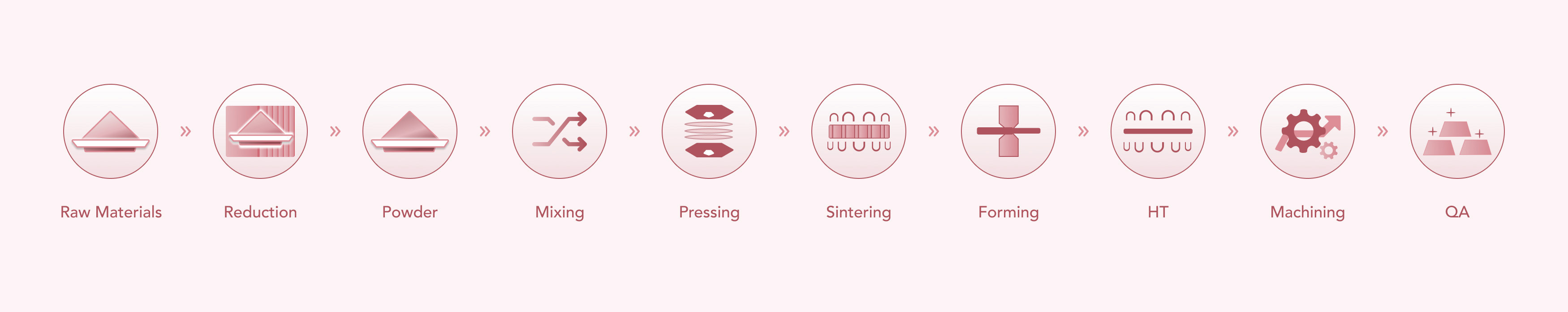

Ytterbium Planar Manufacturing Process:

- Manufacturing Flow: A comprehensive step-by-step process to ensure quality.

- Testing Methods:

- Chemical Composition Analysis: Techniques like GDMS or XRF verify the purity.

- Mechanical Testing: Including tensile strength and elongation.

- Dimensional Inspection: Ensures adherence to size specifications.

- Surface Quality Inspection: Visual and ultrasonic checks for defects.

- Hardness Testing: Assures mechanical reliability and uniformity.

Frequently Asked Questions:

Q1: What is the purity of the Ytterbium Planar Target?

A1: The Ytterbium Planar Target has a purity of 99.9%.

Q2: How should Ytterbium targets be handled?

A2: Store in dry argon and avoid skin contact. Wear gloves and follow cleanroom protocols.

Q3: What sputtering parameters should be used?

A3: Typical sputtering settings include RF power of 80–200 W, argon pressure of 2–5 mTorr, and substrate temperatures between 100–300°C.

Comparison of Ytterbium Rotary Target vs. Ytterbium Planar Target:

|

Feature |

Ytterbium Rotary Target |

Ytterbium Planar Target |

|---|---|---|

|

Material Utilization |

80-90% |

30-40% |

|

Service Life |

Longer |

Shorter |

|

Coating Uniformity |

More uniform |

Thickness variations |

|

Production Cost |

Higher initial cost, more economical long-term |

Lower initial cost, more frequent changes |

|

Applications |

Large-area coatings |

Small-area coatings |

|

Sputtering Stability |

More stable |

Less stable |

|

Compatible Equipment |

Rotary sputtering systems |

Traditional planar sputtering systems |

Related Information:

- Ytterbium Raw Materials: Atomic number 70, melting point 824°C, density 6.97 g/cm³.

- Key Uses: Lasers, atomic clocks, radiation shielding.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.