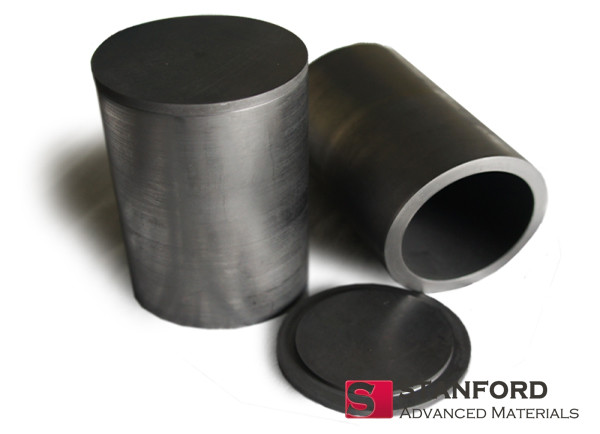

Pyrolytic Graphite Crucible

|

Catalog No. |

GR0191 |

|---|---|

|

Size |

Various |

|

Material |

Pure pyrolytic graphite |

|

Purity |

99% |

|

Shape |

Crucible |

Stanford Advanced Materials (SAM) provides pyrolytic graphite crucible of coated and whole types. We can supply 1~200ml crucibles for whole pyrolytic graphite material and larger sizes are available for coated products. The largest available size for PG coated products can be 350mm*600mm.

Product Overview

Our pyrolytic graphite (PG) crucibles represent the pinnacle of high-temperature containment solutions, engineered for the most demanding metallurgical and semiconductor applications. Manufactured through advanced chemical vapor deposition (CVD) technology, these crucibles deliver unmatched purity and performance in high-value material processing.

Key Features & Benefits

1. Ultra-High Purity Construction

-

CVD process using 99.999% pure methane feedstock

-

Total impurities <10ppm (vs. 100-500ppm in conventional graphite)

-

Ideal for semiconductor crystal growth and high-purity metal evaporation

2. Superior Thermal Performance

-

Continuous operation up to 2300°C (in inert/vacuum)

-

Thermal conductivity: 400-1500 W/m·K (anisotropic)

-

Exceptional thermal shock resistance (ΔT >1500°C)

3. Advanced Material Properties

-

Bulk density: 2.10-2.23 g/cm³

-

Flexural strength: 70-120 MPa

-

Near-zero porosity (<0.5% vs. 10-15% in standard graphite)

4. Custom Engineering Options

-

Available as pure CVD or graphite-substrate coated versions

-

Standard wall thickness: 1mm (custom 0.5-5mm available)

-

Optional silicon carbide coating for enhanced oxidation resistance

Pyrolytic Graphite Crucible Technical Specifications

|

Parameter |

Specification |

|---|---|

|

Material Type |

Pyrolytic Graphite (PG) |

|

Manufacturing Process |

Chemical Vapor Deposition (CVD) |

|

Carbon Content |

99.999% |

|

Maximum Operating Temp |

2300°C (inert/vacuum) |

|

Thermal Conductivity |

400-1500 W/m·K (in-plane) |

|

Density |

2.10-2.23 g/cm³ |

|

Porosity |

<0.5% |

|

Standard Coating Thickness |

30μm (custom 10-500μm) |

|

Lead Time |

3-4 weeks (standard) |

Application Scenarios

Semiconductor Manufacturing

-

MBE and MOCVD systems

-

GaAs, GaN crystal growth

-

Silicon carbide processing

Specialty Metallurgy

-

Ultra-high purity metal evaporation (Al, Au, Ag)

-

Titanium and platinum group metal processing

-

Rare earth element refining

Research & Development

-

High-temperature material studies

-

Thin film deposition systems

-

Advanced battery material development

Contact Our Experts

Have specific application requirements? Our materials engineers are ready to assist with:

-

Material selection guidance

-

Custom design consultation

-

Process optimization advice

-

Technical documentation