Boron Nitride Crucible, BN Crucible

|

Catalog No. |

BN1662 |

|---|---|

|

Size |

Various |

|

Material |

Pure composite boron nitride |

|

Purity |

99% |

|

Shape |

Crucible |

Boron nitride crucibles are available in various forms, purities, sizes, and prices. Other customized BN ceramic products are also available upon your requirements.

Material Properties & Manufacturing

Advanced Hexagonal Boron Nitride (h-BN)

-

Crystal Structure: Hexagonal lattice (h-BN) with graphite-like lubricity

-

Thermal Stability: Maintains performance up to 2973°C in vacuum/inert gas

-

Unique Dual Characteristics:

-

Mechanical: Similar machinability to graphite

-

Electrical: Excellent insulator (>10¹³ Ω·cm)

-

Precision Manufacturing Process

-

Hot-Pressed BN Blank: SAM’s proprietary fabrication ensures >99.5% purity

-

Post-Processing: CNC machining achieves ±0.05mm dimensional tolerance

Product Specifications by Grade

|

Grade |

BN99 (AX05) |

BN-BO (A) |

BNCB (HP) |

BNSIO (M26) |

ZSBN |

|---|---|---|---|---|---|

|

Composition |

hBN>99.5% |

hBN>98% |

hBN>90%+CaBO₃ |

hBN 60%+SiO₂ 40% |

hBN 45%+ZrO₂ 45% |

|

Density (g/cm³) |

1.9 |

2.1 |

2.0 |

2.5-2.6 |

2.9 |

|

Key Advantages |

Ultra-high purity

Best thermal conductivity (30W/mK)> |

Cost-effective

Good moisture resistance |

Optimized for thermal cycling

Spallation resistant |

Enhanced wear resistance

SiO₂ reinforced |

Highest mechanical strength

ZrO₂ toughened |

Standard Product Line

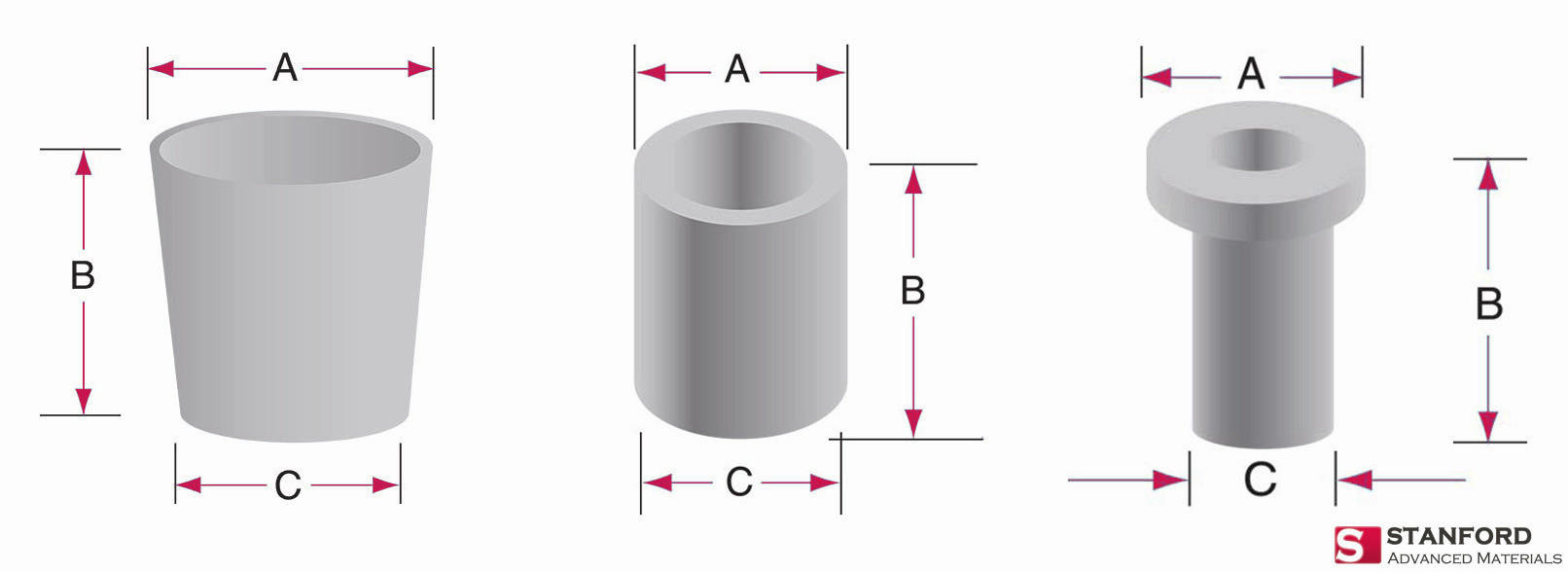

Geometry Options

-

Crucibles: Cylindrical/Conical (25mL-1000mL)

-

Other Forms: Rods (Ø5-100mm), Plates (1-50mm thickness), Custom Tubes

Dimensional Standards

-

Standard Ratios: A:B:C = 1:1.2:0.8 (customizable)

-

Special Features:

-

Pyrometer ports (±0.1mm positioning accuracy)

-

Anti-splash spout designs

-

Multi-chamber configurations

-

Stanford Advanced Materials (SAM) Corporation offers customized service of BN crucible shapes and dimensions for our customers.

Performance Comparison

|

Parameter |

BN Crucible |

||

|---|---|---|---|

|

Max Temp (Inert) |

2973°C |

1800°C |

3000°C |

|

Thermal Shock ΔT |

>1500°C |

200°C |

800°C |

|

Metal Adhesion |

None |

Moderate |

Severe |

|

Oxidation Resistance |

Excellent |

Excellent |

Poor |

Industry Applications

Semiconductor & Electronics

-

MBE/MOCVD Systems: GaAs/GaN crucibles with <0.1ppm contamination

-

Vacuum Feedthroughs: High-voltage insulators (up to 50kV)

Specialty Metallurgy

-

Precious Metals: Au/Ag/Pt melting (99.99% purity retention)

-

Reactive Metals: Ti/Al alloys with zero crucible reaction

Emerging Technologies

-

PV Industry: Silicon ingot growth crucibles

-

Battery Research: Li-metal containment solutions

Packaging

Our BN crucibles are tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage that might be caused during storage or transportation.