Different Types of Evaporation Materials

(주)연진에스텍은 Granule, Beads & Sphere, Lump, Rod, Powder, Single Crystal 등 대부분의 Evaporation Process에 부합하는 다양한 형태의 증발 증착물질을 제공합니다.

Tungsten Titanium (W/Ti) Evaporation

Materials Description

Immerse yourself in the world of cutting-edge thin-film technology with Tungsten Titanium (W/Ti) Evaporation Materials. This innovative alloy seamlessly blends the exceptional properties of tungsten and titanium, pushing the boundaries of thin-film applications. Precision-engineered for versatility, these evaporation materials redefine possibilities in diverse technological landscapes.

Key Features

-

Synergistic Alloy - W/Ti materials leverage the synergies between tungsten and titanium, creating an alloy that excels in thin-film performance with combined benefits.

-

High Melting Points - Harness the elevated melting points contributed by tungsten (3,422°C) and titanium (1,668°C), ensuring stability and resilience in the thin-film deposition process, even in high-temperature applications.

-

Exceptional Thermal Stability - The alloy's composition imparts outstanding thermal stability, a critical characteristic for applications exposed to extreme temperatures.

-

Versatile Applications - W/Ti materials find applications across a spectrum of industries, from electronics to aerospace, owing to their adaptable properties.

Tungsten Titanium Evaporation Materials Specifications

|

Property |

Value |

|---|---|

|

Composition |

Tungsten/Titanium (W/Ti) |

|

Purity |

99.9% |

|

Melting Point |

Tungsten: 3,422°C, Titanium: 1,668°C |

|

Density |

Tungsten: 19.25 g/cm³, Titanium: 4.506 g/cm³ |

|

Thermal Conductivity |

Tungsten: 170 W/m·K, Titanium: 21.9 W/m·K |

|

Coefficient of Expansion |

Tungsten: 4.5 × 10⁻⁶/K, Titanium: 8.6 × 10⁻⁶/K |

Tungsten Titanium Evaporation Materials Applications

-

Microelectronics - W/Ti materials contribute to the manufacturing of advanced microelectronic devices through their application in thin-film technology.

-

Aerospace Industry - Utilized in aerospace applications, W/Ti materials provide reliable thin-film coatings for components exposed to extreme conditions.

-

Optical Devices - The versatility of W/Ti materials makes them suitable for optical coatings, enhancing the performance of various optical devices.

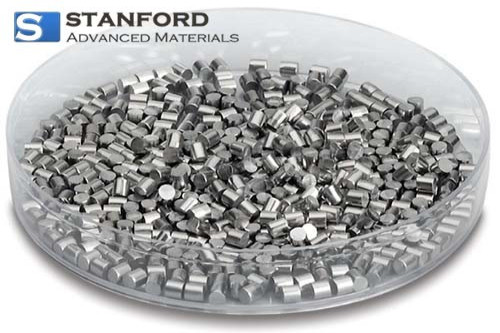

Tungsten Titanium Evaporation Materials Packing

Our Tungsten Titanium (W/Ti) Evaporation Materials undergo meticulous packaging to ensure their integrity during transportation and storage. The materials are hermetically sealed in vacuum packaging and further enclosed in protective outer packaging.

Why Choose Our Tungsten Titanium Evaporation Materials?

-

High Purity - Meeting the highest purity standards, our W/Ti materials ensure the success of thin-film deposition processes.

-

Customization - Tailor the composition and form of W/Ti materials to meet the specific requirements of your thin-film deposition projects, ensuring adaptability for diverse applications.

-

Technical Excellence - Backed by technical expertise, our W/Ti evaporation materials deliver consistent and reliable performance, contributing to the success of your thin-film endeavors.

Embark on the future of thin-film technology with Tungsten Titanium (W/Ti) Evaporation Materials. For inquiries, customizations, or to place an order, please contact us.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.