Different Types of Evaporation Materials

(주)연진에스텍은 Granule, Beads & Sphere, Lump, Rod, Powder, Single Crystal 등 대부분의 Evaporation Process에 부합하는 다양한 형태의 증발 증착물질을 제공합니다.

Chromium Molybdenum Evaporation

Materials Description

Chromium Molybdenum Evaporation Materials, a unique blend of chromium and molybdenum, exhibit a range of exceptional properties that make them highly suitable for various industrial and technological applications. Chromium, a lustrous, hard metal, is known for its corrosion resistance and high melting point, while molybdenum, a silvery-white transition metal, possesses excellent thermal and electrical conductivity.

The combination of these two elements in evaporation materials results in a material that is both strong and thermally stable. These materials can withstand extreme temperatures without significant degradation, making them ideal for use in high-temperature processes such as vacuum deposition and thin-film coating.

Chromium Molybdenum Evaporation Materials also display excellent corrosion resistance, which ensures their durability and longevity even in harsh environments. This property is particularly beneficial in applications where exposure to corrosive substances or oxidizing agents is likely. Furthermore, the high electrical conductivity of molybdenum contributes to the overall performance of these evaporation materials. They can effectively conduct electricity, making them suitable for use in electrical components and devices that require efficient electrical transmission. In addition to their physical properties, Chromium Molybdenum Evaporation Materials are also known for their ability to form strong bonds with other materials. This allows them to be easily integrated into various composite structures, enhancing their performance and durability.

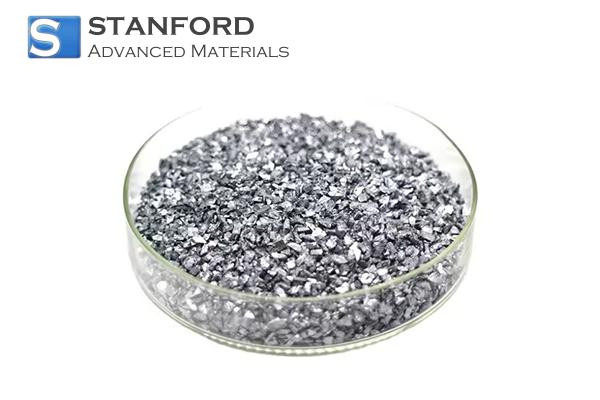

Chromium Molybdenum Evaporation Materials Specification

|

Material |

Chromium Molybdenum |

|

Color/Appearance |

Silvery Metallic |

|

Purity |

99.9% |

Chromium Molybdenum Evaporation Materials Applications

1. Thin-Film Coatings: Chromium Molybdenum Evaporation Materials are often used in vacuum deposition processes to create thin-film coatings on various substrates. These coatings can enhance the surface properties of the substrate, such as improving corrosion resistance, wear resistance, or optical performance. They are commonly applied in the automotive, aerospace, and electronics industries.

2. Optical Coatings: The ability of Chromium Molybdenum Evaporation Materials to form smooth and uniform films makes them suitable for optical coatings. These coatings can be used to enhance the reflectivity, transmittance, or absorption properties of optical components, such as mirrors, lenses, and filters. They are essential in the production of high-performance optical systems in the telecommunications, lasers, and imaging industries.

3. Electrical Components: Chromium Molybdenum Evaporation Materials, due to their excellent electrical conductivity, are used in the manufacturing of electrical components such as contacts, interconnects, and electrodes. They ensure efficient electrical transmission and reliable performance in demanding electrical systems.

4. Decorative Coatings: The lustrous appearance and corrosion resistance of Chromium Molybdenum Evaporation Materials make them suitable for decorative coatings. They can be used to create attractive finishes on various surfaces, including metal parts, jewelry, and automotive trim.

5. Corrosion Protection: The corrosion resistance of Chromium Molybdenum Evaporation Materials allows them to be used in coatings that protect substrates from the harmful effects of environmental factors. These coatings can extend the lifespan and improve the performance of structures and equipment exposed to corrosive environments.

6. Semiconductor Manufacturing: In the semiconductor industry, Chromium Molybdenum Evaporation Materials are used in the deposition of thin films for the creation of electronic devices. They play a crucial role in the development of transistors, diodes, and other components that are essential for modern electronics.

Chromium Molybdenum Evaporation Materials Packaging

Our Chromium Molybdenum Evaporation Materials are carefully handled to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.