Different Types of Evaporation Materials

(주)연진에스텍은 Granule, Beads & Sphere, Lump, Rod, Powder, Single Crystal 등 대부분의 Evaporation Process에 부합하는 다양한 형태의 증발 증착물질을 제공합니다.

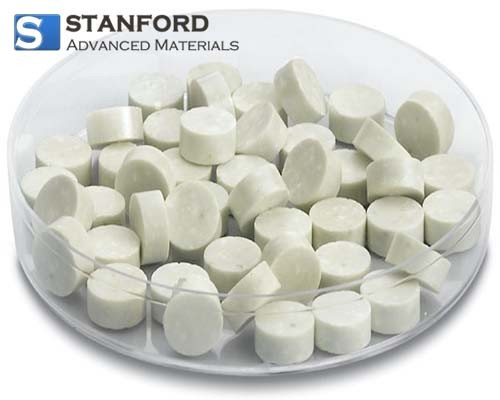

Zinc Oxide Evaporation Materials

Description

Zinc Oxide (ZnO) Evaporation Materials are renowned for their exceptional electrical, optical, and chemical properties, making them highly versatile in various thin-film deposition applications. ZnO exhibits both semiconducting and piezoelectric properties, making it valuable for applications ranging from transparent conductive films in electronic devices to sensors and actuators.

In terms of electrical properties, ZnO demonstrates high electron mobility and a wide bandgap, allowing for the fabrication of high-performance semiconductor devices such as thin-film transistors, light-emitting diodes (LEDs), and solar cells. Its transparent and conductive nature also makes it ideal for use in electrodes and transparent conducting layers in optoelectronic devices.

Optically, ZnO exhibits high transparency in the visible and ultraviolet spectra, along with excellent luminescent properties, making it suitable for applications in UV filters, photodetectors, and light-emitting devices. Its ability to emit light efficiently also contributes to its use in phosphors for lighting and display technologies.

Furthermore, ZnO is chemically stable and biocompatible, making it suitable for use in various biomedical applications such as drug delivery systems, biosensors, and tissue engineering scaffolds.

Zinc Oxide Evaporation Materials Specifications

|

Property |

Value |

|---|---|

|

Material Type |

Zinc Oxide |

|

Symbol |

ZnO |

|

Appearance/Color |

White |

|

Melting Point |

1,974°C (3,585°F) |

|

Density |

5.61 g/cm³ |

|

Purity |

99.99% |

|

Shape |

Powder/Granule/Custom-made |

Zinc Oxide Evaporation Materials Applications

-

Optical Coatings: ZnO thin films are extensively used in the optics industry to create anti-reflective coatings, optical filters, and high-performance mirrors. These coatings enhance the optical properties of various optical components.

-

Electronics: ZnO evaporation materials find application in the electronics industry for the production of thin-film transistors (TFTs), a fundamental component in flat-panel displays like LCDs and OLEDs. Their excellent electrical conductivity and transparency make them ideal for these applications.

-

Photovoltaics: In the field of photovoltaics, ZnO thin films serve as transparent conductive layers, facilitating efficient light absorption and electron transport in solar cells. This enhances the overall efficiency of solar energy conversion.

-

Sensors: ZnO coatings are employed in gas sensors and chemical sensors. Their sensitivity and selectivity make them valuable for applications requiring precise and responsive detection of gases and chemicals.

-

Optoelectronic Devices: ZnO evaporation materials are utilized in the production of various optoelectronic devices, including LEDs, laser diodes, and photodetectors. Their unique optical and electrical properties are highly beneficial in these applications.

Zinc Oxide Evaporation Materials Customization

We understand that specific requirements are essential for many applications. That's why we offer customization options for ZnO Evaporation Materials, including tailored shapes, sizes, and purity levels, to meet your exact needs.

Zinc Oxide Evaporation Materials Packing

Our ZnO Evaporation Materials are meticulously packaged to ensure their quality and integrity during storage and transportation. We take great care to prevent any damage that may occur during handling and delivery.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.