Different Types of Evaporation Materials

(주)연진에스텍은 Granule, Beads & Sphere, Lump, Rod, Powder, Single Crystal 등 대부분의 Evaporation Process에 부합하는 다양한 형태의 증발 증착물질을 제공합니다.

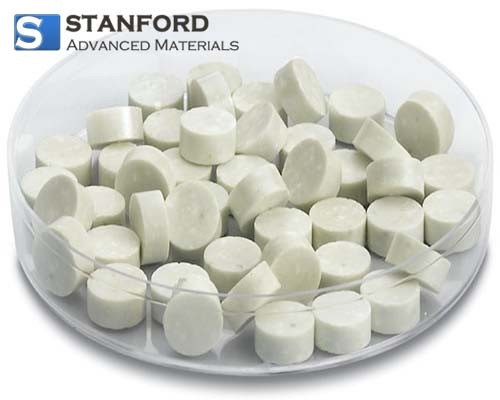

Zinc Oxide with Alumina Evaporation Materials

Description

Zinc Oxide with Alumina (ZnO/Al2O3) Evaporation Materials offer a synergistic combination of the desirable properties of zinc oxide (ZnO) and alumina (Al2O3). This hybrid material provides enhanced thermal stability, mechanical strength, and chemical resistance compared to individual components, making it ideal for demanding thin-film deposition applications.

The incorporation of alumina into zinc oxide matrices improves thermal stability, allowing the material to withstand high temperatures during deposition processes without degradation. This enhanced thermal stability makes ZnO/Al2O3 Evaporation Materials suitable for use in high-temperature vacuum deposition techniques such as thermal evaporation and electron beam evaporation.

Moreover, the addition of alumina enhances the mechanical strength of the material, resulting in improved durability and resistance to mechanical stress during thin-film fabrication and subsequent device operation. This makes ZnO/Al2O3 Evaporation Materials particularly suitable for applications requiring robust thin films, such as optical coatings, protective layers, and wear-resistant coatings.

Furthermore, ZnO/Al2O3 Evaporation Materials exhibit excellent chemical resistance, ensuring compatibility with a wide range of deposition environments and substrate materials. This chemical stability contributes to the reliability and longevity of thin-film coatings deposited using ZnO/Al2O3 Evaporation Materials.

Zinc Oxide with Alumina Evaporation Materials Specifications

|

Property |

Value |

|---|---|

|

Material Type |

Zinc Oxide with Alumina |

|

Symbol |

ZnO/Al2O3 |

|

Appearance/Color |

White |

|

Melting Point |

Approx. 2,030°C (3,686°F) |

|

Density |

3.8 g/cm³ |

|

Purity |

99.9% |

|

Shape |

Powder/Granule/Custom-made |

Zinc Oxide with Alumina Evaporation Materials Applications

-

Optical Coatings: ZnO/Al2O3 thin films are widely used in the optics industry to create anti-reflective coatings, optical filters, and high-performance mirrors, enhancing the optical properties of various optical components.

-

Electronics: These materials are employed in the electronics industry for the production of thin-film transistors (TFTs), which are essential components in flat-panel displays like LCDs and OLEDs. Their excellent electrical conductivity and transparency make them ideal for these applications.

-

Photovoltaics: ZnO/Al2O3 thin films are crucial in the manufacturing of solar cells. They serve as transparent conductive layers that facilitate efficient light absorption and electron transport, improving solar cell efficiency.

-

Sensors: In gas sensors and chemical sensors, ZnO/Al2O3 coatings enhance sensitivity and selectivity, making them valuable in applications requiring precise and responsive detection.

-

Optoelectronic Devices: These materials are used in the production of optoelectronic devices such as LEDs, laser diodes, and photodetectors, where their optical and electrical properties are highly beneficial.

Zinc Oxide with Alumina Evaporation Materials Customization

At Stanford Advanced Materials, we understand that specific requirements are crucial for many applications. We offer customization options for ZnO/Al2O3 Evaporation Materials, including tailored shapes, sizes, and purity levels to meet your exact needs.

Zinc Oxide with Alumina Evaporation Materials Packing

Our ZnO/Al2O3 Evaporation Materials are carefully packaged to ensure their quality and integrity during storage and transportation. We take great care to prevent any damage that may occur during handling and delivery.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.