Different Types of Evaporation Materials

(주)연진에스텍은 Granule, Beads & Sphere, Lump, Rod, Powder, Single Crystal 등 대부분의 Evaporation Process에 부합하는 다양한 형태의 증발 증착물질을 제공합니다.

Aluminum Copper (Al/Cu) Evaporation

Materials Description

Aluminum Copper Evaporation Materials are created by physically vaporizing a mixture of aluminum and copper metals under vacuum conditions. This process results in the formation of a thin film of aluminum-copper alloy on a substrate or target material.

These materials are commonly used in various applications such as thin-film deposition processes in the semiconductor industry, optical coatings, and decorative films. Aluminum-copper films can provide improved electrical conductivity, corrosion resistance, and thermal stability compared to pure aluminum films. Additionally, the composition of the alloy can be adjusted to achieve specific properties and performance requirements.

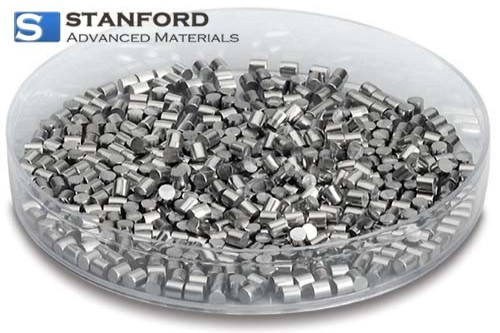

Aluminum Copper Evaporation Materials are available in various forms, including pellets, wires, and crucibles, to suit different deposition methods such as electron beam evaporation and thermal evaporation. They are also offered with different compositions and ratios of aluminum and copper to meet specific application needs.

Aluminum Copper (Al/Cu) Evaporation Materials Specifications

|

Material |

Aluminum Copper (Al/Cu) |

|

Purity |

99.9% ~ 99.999% |

|

Shape |

Powder/ Granule/ Custom-made |

|

Composition |

Customized |

Aluminum Copper (Al/Cu) Evaporation Materials Applications

1. Display Technology: AlCu evaporation materials are utilized in the production of flat panel displays, such as LCD (liquid crystal display) and OLED (organic light-emitting diode) screens. These materials are used for the deposition of conductive layers and interconnects within the display structure.

2. Semiconductor Manufacturing: AlCu films are employed in the manufacturing of microelectronic devices and integrated circuits (ICs). They are used as a conducting layer for interconnects, bonding pad structures, and other conductive elements on silicon chips.

3. Solar Cells: AlCu evaporation materials are used in the production of thin-film solar cells. They help create conducting layers and contacts within the solar cell structure, contributing to efficient electricity generation.

4. Optics and Photonics: Aluminum copper films can be used as reflective coatings for mirrors, lenses, and other optical elements. These coatings improve reflectivity and durability, making them suitable for applications in telescopes, lasers, and optical data storage devices.

5. Decorative Coatings: Aluminum copper films can create visually appealing, metallic surfaces in various applications such as automotive trim, architectural finishes, and electronic devices. The thin layers of AlCu can provide an aesthetic look while offering protection against corrosion and wear.

6. Aerospace Industry: AlCu coatings can be used for corrosion-resistant layers on aircraft components and structures. These coatings can protect the underlying materials from environmental degradation and offer improved resistance to wear and damage.

7. Magnetic Recording Media: Aluminum copper films are utilized in the production of magnetic storage media, such as computer hard disk drives. The films act as an adhesive layer that allows the deposition of the magnetic storage layer onto the substrate.

Aluminum Copper (Al/Cu) Evaporation Materials Packaging

Our Aluminum Copper (Al/Cu) Evaporation Materials is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.