Different Types of Evaporation Materials

(주)연진에스텍은 Granule, Beads & Sphere, Lump, Rod, Powder, Single Crystal 등 대부분의 Evaporation Process에 부합하는 다양한 형태의 증발 증착물질을 제공합니다.

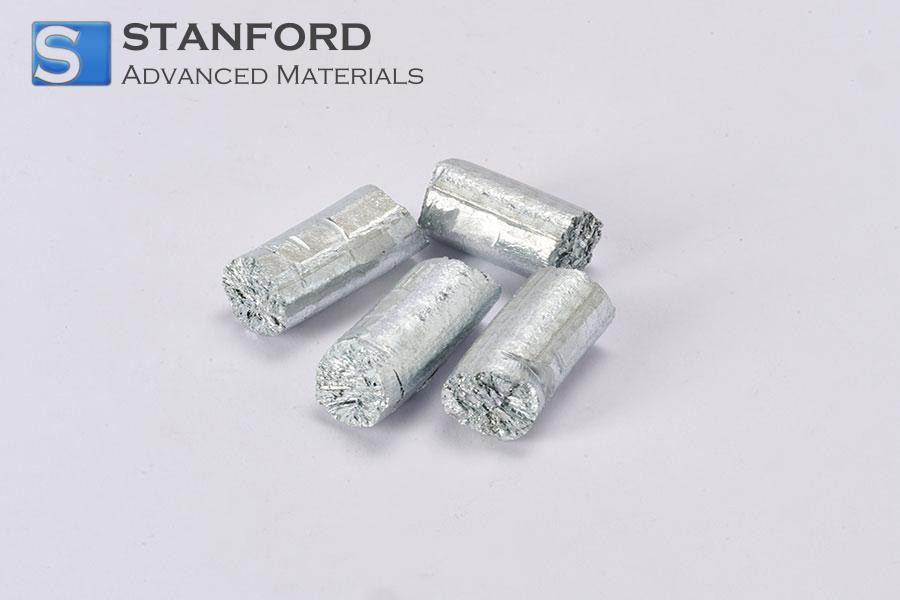

Zinc Evaporation Materials Description

Zinc Evaporation Materials exhibit excellent thermal stability, ensuring a smooth and consistent evaporation process. This characteristic enables the formation of uniform and high-quality coatings, crucial for achieving desired functional properties.

Moreover, Zinc Evaporation Materials possess good electrical conductivity, making them a prime choice for applications in the field of electronics. This allows for the creation of coatings that enhance the electrical performance of devices and components.

Furthermore, Zinc Evaporation Materials demonstrate good adhesion to various substrates, ensuring a strong and durable bond between the coating and the underlying material. This adhesion strength is crucial for maintaining the integrity and performance of the coating over time.

Additionally, Zinc Evaporation Materials are relatively inexpensive and easy to process, making them a cost-effective solution for large-scale production. They can be easily deposited using various evaporation techniques, such as vacuum evaporation or sputtering.

Zinc (Zn) Evaporation Materials Specification

|

Material |

Zinc |

|

Atomic Weight |

65.38 |

|

Color/Appearance |

Bluish Pale Gray, Metallic |

|

Thermal Conductivity |

116 W/m.K |

|

Melting Point (°C) |

420 |

|

Coefficient of Thermal Expansion |

30.2 x 10-6/K |

|

Theoretical Density (g/cc) |

7.14 |

|

Z Ratio |

0.514 |

|

Temp. (°C) for Given Vap. Press. (Torr) |

10^-8: 127 10^-6:177 10^-4:250 |

Zinc (Zn) Evaporation Materials Applications

• Used in deposition processes including semiconductor deposition, chemical vapor deposition (CVD) and physical vapor deposition (PVD)

• Used for optics including wear protection, decorative coatings, and displays.

Zinc (Zn) Evaporation Materials Packaging:

Our evaporation materials are carefully handled to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.