Different Types of Evaporation Materials

(주)연진에스텍은 Granule, Beads & Sphere, Lump, Rod, Powder, Single Crystal 등 대부분의 Evaporation Process에 부합하는 다양한 형태의 증발 증착물질을 제공합니다.

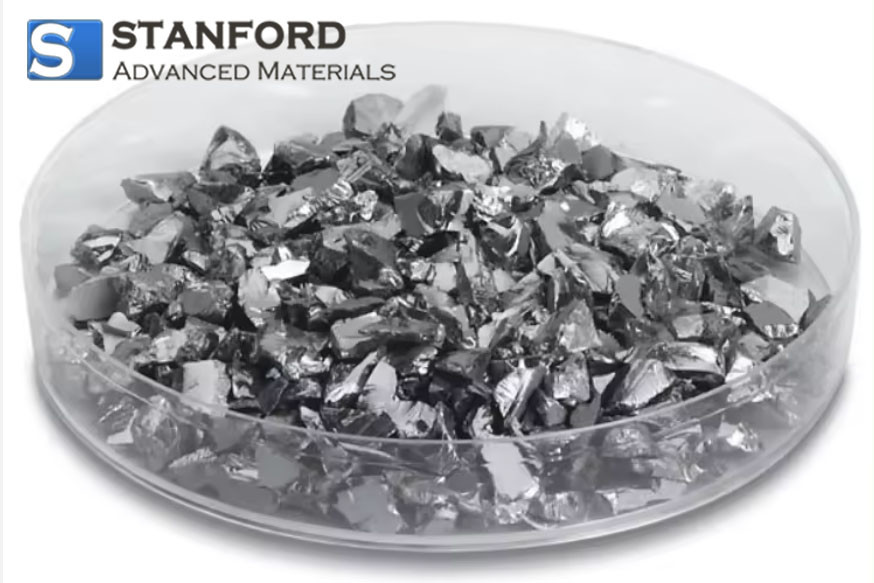

Silicon (Si) (undoped) Evaporation Materials

Description:

Silicon is a metalloid and carries the typical properties of both metals and nonmetals. It is extremely inert and insoluble in water and acids. However, it can be dissolved into silicates by hot alkaline lyes. Pure silicon forms dark gray, metallic, shiny crystals. Silicon also has excellent thermal conductivity, which – in pure silicon – is accompanied by extremely low electrical conductivity. When alloyed with aluminium, it enhances strength and reduces weight.

High purity evaporation materials play a huge role in deposition processes to ensure high quality deposited film. Stanford Advanced Materials (SAM) specializes in producing up to 99.999% purity silicon evaporation materials using quality assurance processes to guarantee product reliability.

Silicon (Si) (undoped) Evaporation Materials Specification

|

Material |

Silicon |

|

Atomic Weight |

28.0855 |

|

Color/Appearance |

Dark Gray with a Bluish Tinge, Semi-Metallic |

|

Thermal Conductivity |

150 W/m.K |

|

Melting Point (°C) |

1,410 |

|

Bulk Resistivity |

0.005-0.020 OHM-CM |

|

Coefficient of Thermal Expansion |

2.6 x 10-6/K |

|

Theoretical Density (g/cc) |

2.32 |

|

Z Ratio |

0.712 |

|

Temp. (°C) for Given Vap. Press. (Torr) |

10^-8: 992 10^-6: 1,147 10^-4: 1,337 |

Silicon (Si) (undoped) Evaporation Materials Applications

1. Optical Coatings: Undoped Silicon Evaporation Materials are often used in the deposition of optical coatings. These coatings can enhance the optical properties of surfaces, such as reflectivity, transmittance, or absorption, depending on the desired application. Silicon coatings are particularly useful in optical systems, lasers, and other devices where precise control of light interaction is crucial.

2. Thin-Film Transistors: In the production of thin-film transistors (TFTs), undoped Silicon Evaporation Materials are employed to deposit silicon films on substrates. TFTs are widely used in displays, such as liquid crystal displays (LCDs) and organic light-emitting diode (OLED) displays, where they control the flow of current through the display pixels.

3. Semiconductor Device Manufacturing: Although undoped silicon is not directly used for doping in semiconductor device manufacturing, it can serve as a base material for subsequent doping processes. It can also be used to deposit insulating layers or as a protective coating in semiconductor devices.

4. Solar Cell Manufacturing: While doped silicon is typically used in solar cell production, undoped Silicon Evaporation Materials can still play a role. They can be used to deposit thin films or layers that serve as protective coatings, anti-reflection coatings, or as part of the solar cell structure.

5. Research and Development: In research and development settings, undoped Silicon Evaporation Materials are invaluable. Scientists and engineers can use them to explore new material properties, develop novel device structures, and investigate fundamental physical phenomena related to silicon.

Silicon (Si) (undoped) Evaporation Materials Packaging:

Our evaporation materials are carefully handled to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.