Different Types of Evaporation Materials

(주)연진에스텍은 Granule, Beads & Sphere, Lump, Rod, Powder, Single Crystal 등 대부분의 Evaporation Process에 부합하는 다양한 형태의 증발 증착물질을 제공합니다.

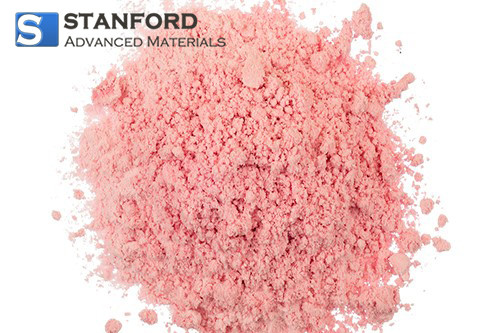

Manganese Fluoride Evaporation Materials

Description

Explore the exceptional attributes of Manganese Fluoride (MnF2) Evaporation Materials and delve into their versatile applications across various industries. This page provides insights into the key features, applications, and advantages of integrating Manganese Fluoride into thin film deposition processes.

Manganese Fluoride Evaporation Materials Specification

|

Specification |

Details |

|---|---|

|

Material Type |

Manganese(II) Fluoride |

|

Symbol |

MnF2 |

|

Appearance/Color |

Pale pink crystalline |

|

Melting Point |

856 °C (1,573 °F; 1,129 K) |

|

Density |

3.98 g/cm3 |

|

Purity |

99.9% |

|

Shape |

Powder/ Granule/ Custom-made |

Manganese Fluoride Evaporation Materials Key Characteristics

-

Chemical Composition: Manganese Fluoride (MnF2) comprises manganese (Mn) and fluorine (F), forming a distinctive pale pink crystalline solid.

-

Moderate Melting Point: MnF2 possesses a moderate melting point of 856 °C (1,573 °F; 1,129 K), allowing it to endure the elevated temperatures necessary for thermal evaporation without untimely vaporization.

-

Density: With a density of 3.98 g/cm3, Manganese Fluoride boasts substantial mass, contributing to its stability during the thin film deposition process.

Manganese Fluoride Evaporation Materials Applications

1. Optical Coatings: Manganese Fluoride thin films find applications in optical coatings for lenses, mirrors, and various optical components. Its refractive properties make it valuable for managing light transmission and reflection.

2. Photovoltaics: Manganese Fluoride is employed in photovoltaic applications to enhance light absorption and optimize energy conversion efficiency in solar cells.

3. Catalysts: In catalysis, Manganese Fluoride can serve as a catalyst support or as an active catalyst itself in certain reactions, benefiting various chemical processes.

4. Semiconductor Manufacturing: Manganese Fluoride is utilized in semiconductor manufacturing processes, contributing to the creation of electronic devices with specific functionalities.

Manganese Fluoride Evaporation Materials Benefits

-

Optical Enhancement: Manganese Fluoride's optical properties, including its refractive behavior, contribute to improved optical performance in coatings and devices.

-

Energy Efficiency: In photovoltaic applications, Manganese Fluoride assists in maximizing energy conversion efficiency, a crucial factor in solar cell technology.

-

Catalytic Potential: Its role as a catalyst or catalyst support promotes efficient and selective chemical transformations in various industrial applications.

-

Tailored Electronics: In the semiconductor industry, Manganese Fluoride assists in crafting electronic devices with desired electronic properties.

Uncover the potential of Manganese Fluoride (MnF2) Evaporation Materials and harness their remarkable properties for innovative applications across diverse industries.

Manganese Fluoride Evaporation Materials Packing

Our Manganese Fluoride (MnF2) Evaporation Materials are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage caused during storage or transportation.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.