Different Types of Evaporation Materials

(주)연진에스텍은 Granule, Beads & Sphere, Lump, Rod, Powder, Single Crystal 등 대부분의 Evaporation Process에 부합하는 다양한 형태의 증발 증착물질을 제공합니다.

Iron Carbide Evaporation Materials

Description

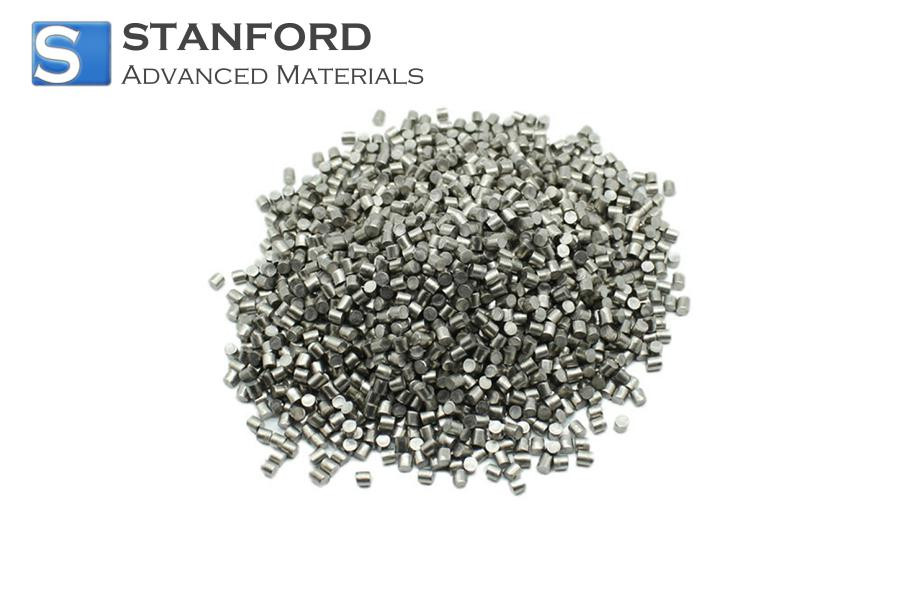

Iron Carbide (Fe3C) is a versatile material known for its use in various applications, including evaporation processes. It is a gray to black solid with a melting point of approximately 1,505°C (2,741°F; 1,778 K). This material exhibits a density of 7.694 g/cm³ and boasts a high purity level of 99.5%. Iron Carbide is available in various forms, including powder, granules, and custom-made shapes, making it adaptable for different deposition methods.

Iron Carbide Evaporation Materials Specifications

|

Specification |

Value |

|---|---|

|

Material Type |

Iron Carbide (Fe3C) |

|

Symbol |

Fe3C |

|

Appearance/Color |

Gray to Black Solid |

|

Melting Point |

Approximately 1,505°C (2,741°F; 1,778 K) |

|

Density |

7.694 g/cm³ |

|

Purity |

99.5% |

|

Shape |

Powder/Granule/Custom-made |

Iron Carbide Evaporation Materials Applications

Cutting Tools: Fe3C coatings enhance the hardness and wear resistance of cutting tools, prolonging their lifespan and improving cutting efficiency in machining operations.

2. Automotive Components: These materials are used for coating automotive components such as engine parts, gears, and valves, providing them with improved durability and resistance to wear and corrosion.

3. Semiconductor Devices: Fe3C films can be employed as protective coatings for semiconductor devices, ensuring their reliability and longevity in harsh operating conditions.

4. Surface Engineering: Fe3C coatings are utilized in surface engineering applications to improve the performance and durability of mechanical components in various industries, including aerospace and manufacturing.

5. Tool Coatings: Fe3C evaporation materials are utilized to deposit thin films on tool surfaces, enhancing their resistance to abrasion, friction, and chemical degradation, thereby improving tool performance and efficiency.

6. Tribological Applications: Fe3C coatings are employed in tribological applications where high wear resistance and low friction are required, such as in bearings, gears, and sliding components.

Iron Carbide Evaporation Materials Packaging

Our Iron Carbide Evaporation Materials are carefully packaged to ensure their integrity during transportation and storage. We offer various packaging options to meet your specific needs.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.