Different Types of Evaporation Materials

(주)연진에스텍은 Granule, Beads & Sphere, Lump, Rod, Powder, Single Crystal 등 대부분의 Evaporation Process에 부합하는 다양한 형태의 증발 증착물질을 제공합니다.

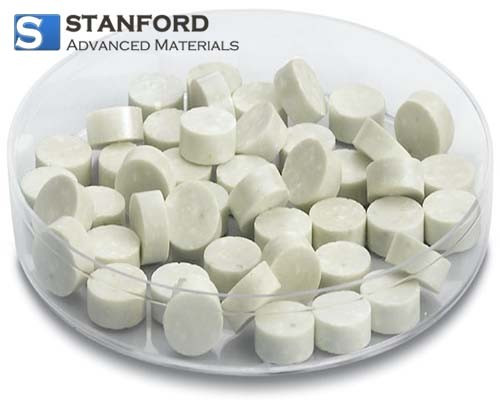

Strontium Zirconate Evaporation Materials

Description

Strontium zirconate evaporation material from Stanford Advanced Materials is an oxide evaporation material with the chemical formula SrZrO3. High-purity SrZrO3 evaporation materials play a huge role in deposition processes to ensure high-quality deposited film. Stanford Advanced Materials (SAM) specializes in producing up to 99.9995% purity evaporating materials using quality assurance processes to guarantee product reliability.

Strontium Zirconate Evaporation Materials Specification

|

Compound Formula |

SrZrO3 |

|

Molecular Weight |

226.84 |

|

Appearance |

White to off-white powder or crystals |

|

Melting Point |

2700 °C |

|

Boiling Point |

9000 °C |

|

Density |

5.5 g/cm3 (20 °C) |

Strontium Zirconate Evaporation Materials Application

Solid Oxide Fuel Cells (SOFCs): Strontium zirconate is used as an electrolyte material in SOFCs due to its high ionic conductivity at elevated temperatures, enabling efficient conversion of chemical energy into electrical energy.

2. Oxygen sensors: Employed as a sensing material in oxygen sensors and gas detectors, where the high oxygen ion conductivity of strontium zirconate allows for accurate measurement of oxygen partial pressure in gases and liquids.

3. Catalysis: Used as a catalyst support material in heterogeneous catalysis, particularly in reactions involving oxygen activation and conversion, due to its high surface area and chemical stability under harsh reaction conditions.

4. Membrane separation: Strontium zirconate membranes are utilized in membrane separation processes, such as oxygen separation from air and hydrogen purification, due to their high oxygen ion conductivity and selectivity.

5. Thermal barrier coatings: Applied as a thermal barrier coating in gas turbine engines and other high-temperature applications, where strontium zirconate provides thermal insulation and protection against corrosion and oxidation.

Strontium Zirconate Evaporation Materials Packaging

Our strontium zirconate evaporation materials are carefully handled to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.