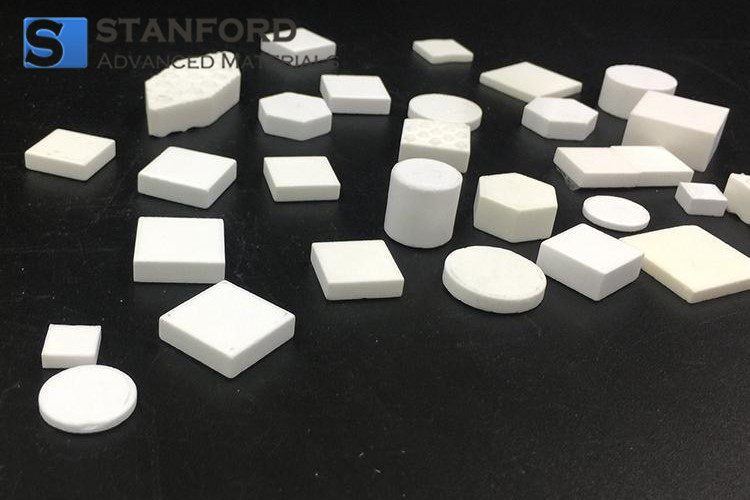

Different Types of Evaporation Materials

(주)연진에스텍은 Granule, Beads & Sphere, Lump, Rod, Powder, Single Crystal 등 대부분의 Evaporation Process에 부합하는 다양한 형태의 증발 증착물질을 제공합니다.

Aluminum Oxide (Al₂O₃) Evaporation Materials

Description

Aluminum Oxide (Al₂O₃) Evaporation Materials are meticulously engineered for precision in thin-film deposition processes. These materials play a crucial role in the production of coatings with specific optical and electrical properties, making them essential in various technological applications.

Key Features

-

High Purity - Our Al₂O₃ Evaporation Materials boast exceptional purity, ensuring the deposition of films free from contaminants that could compromise performance.

-

Stoichiometric Composition - The precise stoichiometric composition of aluminum oxide enhances its performance, making it a reliable choice for applications demanding accuracy.

-

Uniform Deposition - Achieve uniform and controlled film deposition, thanks to the high-quality manufacturing of our Aluminum Oxide Evaporation Materials.

-

Versatility - Suitable for a range of applications, from optical coatings to semiconductor devices, where precision and reliability are paramount.

Aluminum Oxide (Al₂O₃) Evaporation Materials Specifications

|

Property |

Value |

|---|---|

|

Chemical Formula |

Al₂O₃ |

|

Purity |

99.99% |

|

Melting Point |

2,072°C |

|

Density |

3.95 g/cm³ |

|

Thermal Conductivity |

30 W/m·K |

|

Refractive Index (at 550nm) |

1.77 |

|

Crystal Structure |

Hexagonal (Corundum) |

Aluminum Oxide (Al₂O₃) Evaporation Materials Applications

-

Optical Coatings - Al₂O₃ is extensively used in the production of optical coatings, providing specific refractive indices for lenses, mirrors, and other optical elements.

-

Semiconductor Devices - As a thin-film material, aluminum oxide finds applications in semiconductor devices, contributing to their electrical insulation and passivation layers.

-

Wear-Resistant Coatings - The hardness and durability of Al₂O₃ make it an ideal choice for wear-resistant coatings on various surfaces.

Aluminum Oxide (Al₂O₃) Evaporation Materials Packing

Our Aluminum Oxide Evaporation Materials are meticulously packed to ensure their integrity during transportation and storage. The standard packing includes vacuum-sealed plastic bags within a protective outer case.

Why Choose Our Aluminum Oxide (Al₂O₃) Evaporation Materials?

-

Quality Assurance - Our materials undergo stringent quality checks to ensure they meet the highest industry standards.

-

Precision - The stoichiometric composition and purity of our Al₂O₃ materials make them a precise choice for thin-film deposition.

-

Versatility - Whether for optical coatings, semiconductor applications, or wear-resistant coatings, our Aluminum Oxide Evaporation Materials offer versatility in performance.

For inquiries, customization, or to place an order, feel free to reach out. Elevate your thin-film deposition processes with Aluminum Oxide (Al₂O₃) Evaporation Materials.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.