Different Shapes of Sputtering Targets

(주)연진에스텍은 Planar (flat) Target과 Rotary (cylindrical) Target, Circular Target 및 Ring Target 등 대부분의 증착 공정에 부합하는 다양한 형태의 스퍼터링 타겟을 제공하며, 타겟 크기의 커스터마이즈가 가능합니다.

Boron Oxide-doped Lithium Phosphate

Product Overview

Stanford Advanced Materials (SAM) presents the Boron Oxide-Doped Lithium Phosphate Target (Li₃PO₄: B₂O₃), a premium sputtering material meticulously developed for solid-state electrolyte and thin film applications. This target is engineered to deliver superior ionic conductivity and enhanced stability, making it ideal for cutting-edge lithium battery technologies and advanced microelectronic devices.

B2O3 Key Specifications

- Material: Li₃PO₄: B₂O₃

- Purity: 99.9%

- Shape: Planar Disc

Note: Specifications provided are based on theoretical data. For customized specifications and detailed inquiries, please contact our sales team.

B2O3 Product Description

The Boron Oxide-Doped Lithium Phosphate Target (Li₃PO₄: B₂O₃) combines the robust properties of lithium phosphate with the versatile characteristics of boron oxide. Lithium phosphate (Li₃PO₄) is renowned for its exceptional chemical stability, broad electrochemical window, and commendable ionic conductivity, making it a standout candidate for solid-state electrolytes. By doping with boron oxide (B₂O₃), the glassy structure of lithium phosphate is enhanced, promoting an amorphous nature that boosts ionic mobility. This doped target excels in forming uniform, high-quality thin films with excellent compatibility across various substrates. It maintains structural integrity during the sputtering process, offers superior thermal stability, and ensures the deposition of smooth, stoichiometrically consistent films. These features render it perfect for applications like thin-film batteries, protective electrode coatings, and sophisticated microelectronic components.

B2O3 Applications

- Solid-State Lithium Batteries: Acts as a solid electrolyte layer, enhancing ionic conductivity and overall battery performance.

- Protective Electrode Coatings: Prevents electrode degradation, thereby extending battery life and reliability.

- Microelectronics: Utilized in ion-conductive films essential for advanced microelectronic devices.

- Energy Storage Devices: Facilitates stable and uniform thin film deposition crucial for next-generation energy storage solutions.

- Research and Development: Ideal for developing all-solid-state batteries and microbattery systems due to its superior film-forming capabilities.

B2O3 Packaging

Our Boron Oxide-Doped Lithium Phosphate Targets are packaged with precision to ensure their safety and integrity during transit and storage. Depending on the size, smaller targets are securely packed in polypropylene (PP) boxes, while larger ones are shipped in bespoke wooden crates. We prioritize customized packaging solutions and utilize appropriate cushioning materials to provide maximum protection.

Packaging Options:

- Carton

- Wooden Crate

- Custom Packaging

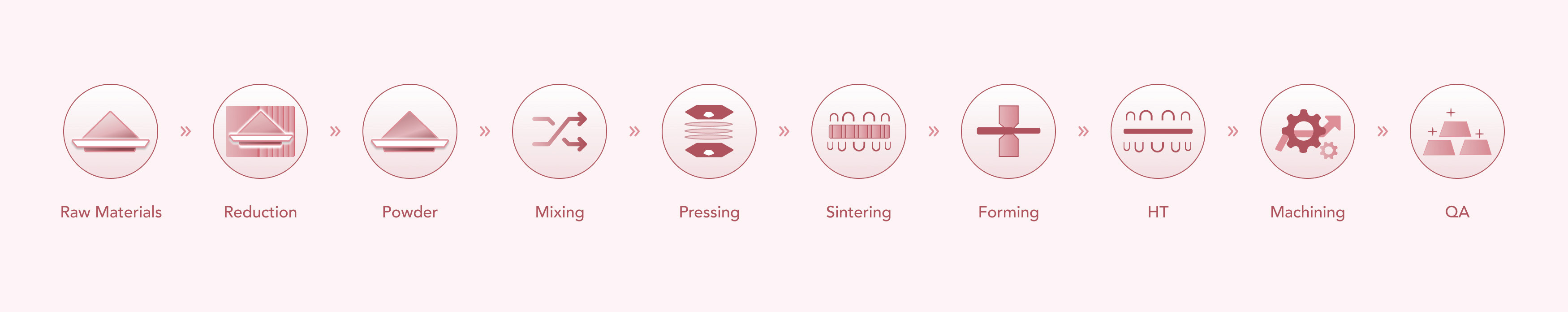

Manufacturing Process

Manufacturing Workflow

Testing Methods

- Chemical Composition Analysis: Ensure material purity and accurate composition using techniques like Glow Discharge Mass Spectrometry (GDMS) or X-ray Fluorescence (XRF).

- Mechanical Properties Testing: Assess tensile strength, yield strength, and elongation to determine material performance under stress.

- Dimensional Inspection: Measure thickness, diameter, and other dimensions to confirm compliance with specified tolerances.

- Surface Quality Inspection: Detect defects such as scratches, cracks, or inclusions through visual and ultrasonic examinations.

- Hardness Testing: Evaluate material hardness to ensure uniformity and mechanical reliability.

Frequently Asked Questions

Q1: What benefits does Boron Oxide-Doped Lithium Phosphate offer as a sputtering target?

A1: It provides outstanding ionic conductivity, exceptional chemical stability, and excellent film-forming properties, making it ideal for applications in thin-film batteries and other electrochemical devices.

Q2: What are the common uses of Li₃PO₄: B₂O₃ targets?

A2: These targets are primarily used in the production of solid-state lithium-ion batteries, thin-film batteries, and as solid electrolytes or protective layers in various electrochemical devices.

Q3: Is the target compatible with both RF and DC sputtering systems?

A3: Yes, the Boron Oxide-Doped Lithium Phosphate Target is suitable for use in both RF and DC sputtering techniques, depending on the specific system design and process requirements.

Performance Comparison: Li₃PO₄: B₂O₃ vs. Competing Materials

| Property | Li₃PO₄: B₂O₃ | Li₃PO₄ (Standard) | LiFePO₄ | YBCO (YBa₂Cu₃O₇) | STO (SrTiO₃) |

| Composition | Li₃PO₄ doped with B₂O₃ | Pure Li₃PO₄ | Olivine LiFePO₄ | Yttrium Barium Copper Oxide | SrTiO₃ Perovskite |

| Purity | 95%+ | 99% | 99% | 99.99% | 99.95% |

| Ionic Conductivity (S/cm) | ~1×10⁻⁴ (optimized) | ~1×10⁻⁵ | ~1×10⁻¹⁴ | Superconducting (below Tc) | High resistivity (~10¹² Ω·cm) |

| Thermal Stability (°C) | Up to 1200 | Up to 1000 | Up to 800 | Up to 900 (sintering) | Up to 1400 |

| Key Applications | Radiation detectors, optoelectronic films | Solid electrolytes, interface coatings | Cathodes for lithium-ion batteries | Superconducting films, quantum devices | Dielectric layers, substrates |

| Form (Target) | Custom shapes (disc, rectangular) | Powder, thin films | Pellets, powders | Sputtering targets | Single-crystal substrates |

Raw Materials Information

Lithium (Li)

Lithium is a soft, silvery-white alkali metal with atomic number 3, recognized as the lightest metal and one of the most reactive elements. It is highly flammable and reacts vigorously with water to produce lithium hydroxide and hydrogen gas. Due to its low atomic mass and high electrochemical potential, lithium is indispensable in energy storage systems, particularly in lithium-ion and lithium-polymer batteries. Additionally, lithium is utilized in ceramics, glass production, aerospace alloys, and nuclear fusion processes. In thin film and sputtering applications, lithium compounds are essential as cathode materials for rechargeable batteries.

Phosphorus (P)

Phosphorus is a non-metallic element with atomic number 15, existing in multiple allotropic forms, predominantly white and red phosphorus. It is vital for all living organisms, being a fundamental component of DNA, RNA, and ATP. Industrially, phosphorus is extensively used in fertilizers, flame retardants, metallurgy, and specialty glass and coatings due to its reactive and versatile nature.

Boron (B)

Boron is a metalloid with atomic number 5, known for its high melting point, complex bonding characteristics, and diverse structural forms. It plays a crucial role in the production of borosilicate glass, ceramics, semiconductors, and composite materials. Boron compounds, such as boric acid and boron carbide, are valued for their thermal stability, hardness, and applications in advanced materials, including nuclear reactors and permanent magnets.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.