HPT-300 & HPT-500

The HPT-300 & HPT-500 are microprocessor controlled benchtop plasma treatment systems which are ideally suited to surface activation, cleaning and modification of a wide range of materials including polymers, metals, glass and ceramics.

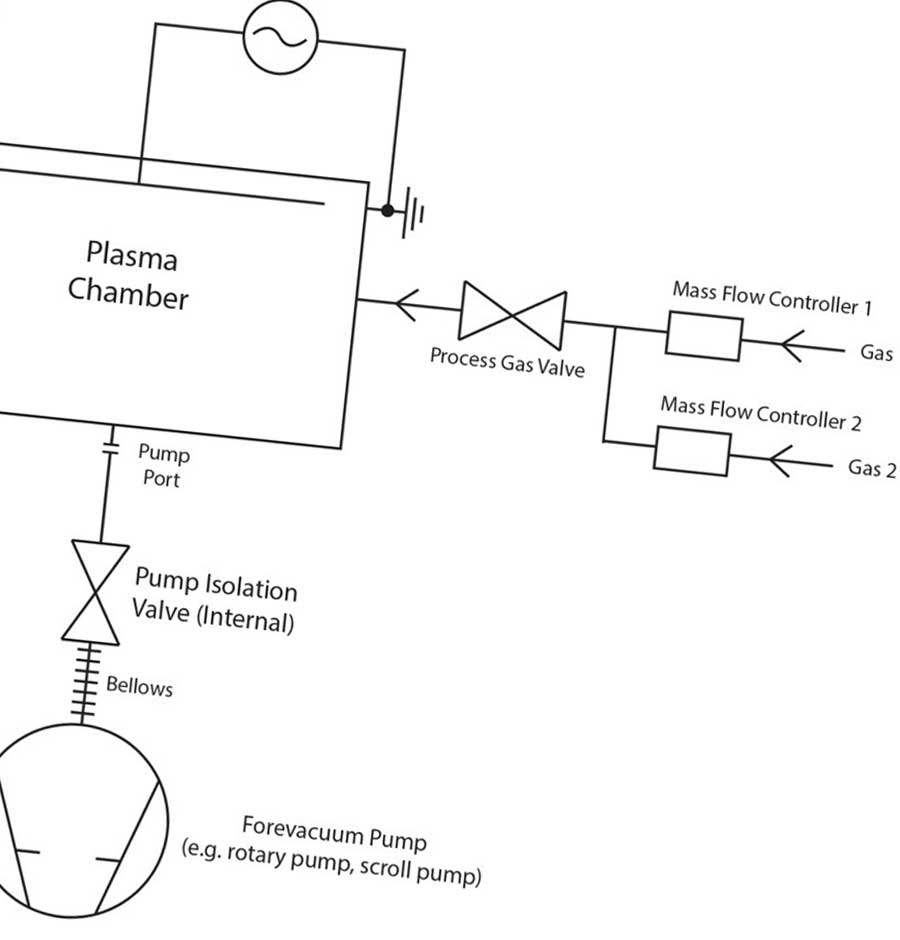

Available in single or dual gas inlet versions and with onboard gas mixing manifold, the HPT-300/500 systems are able to handle a wide range of gases for optimised treatments, including air, oxygen, hydrogen, argon, nitrogen and many others.

An optional vapour delivery inlet extends the use to liquid precursors and a corrosion-resistant version expands the choice even further to address specific material treatments including;

- Plasma cleaning

- Plasma surface activation to improve adhesion

- Functional plasma coatings

- Plasma etching

- PDMS & microfluidic devices

- PEEK & other engineering polymers

- PTFE

- Metals

- Ceramics

- Glass & optical devices

PROCESS RESULTS

TFT Colour touchscreen

Each system is supplied with a 5.7" colour touchscreen provides a rich, user-friendly interface. Variables such as gas flow rate, pressure, power level and plasma processing time can be freely set and then stored to produce a fully interlocked process cycle from a single keypress. A handy status display and end of process audible alarm informs the user of every step in the process.

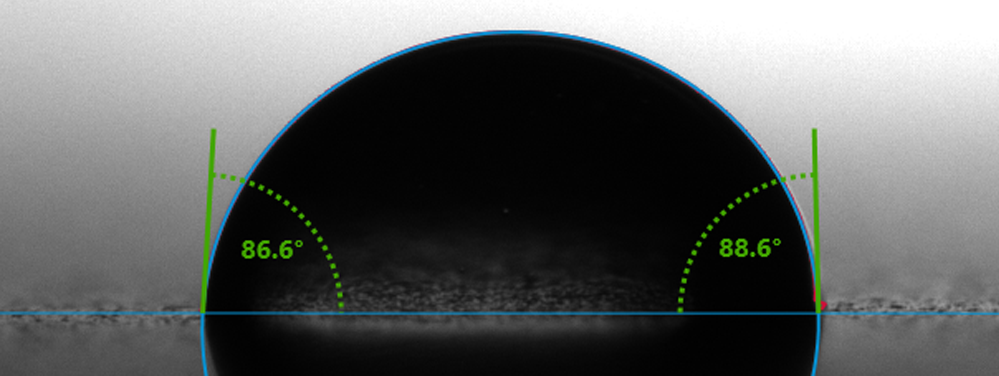

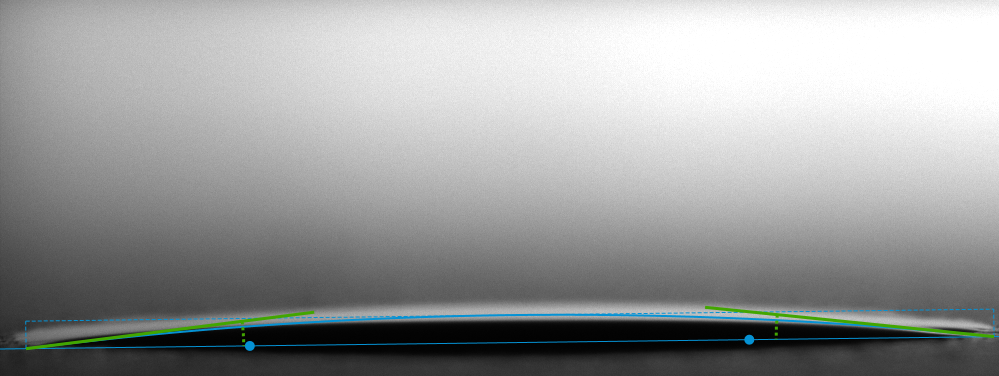

Surface Activation Example

- Material : PEEK

- Oxygen Plasma

- 60 seconds

Before plasma treatment

After plasma treatment

PLASMA ENVIRONMENT

Vacuum chamber & power

The HPT-300 system features a 200mm x 200mm (~12.5L) rectangular plasma process chamber in stainless steel with vacuum compatible materials throughout.

The HPT-500 feature a 240 x 240mm (~23L) rectangular plasma process chamber respectively. Both models feature removable parts/carrier trays which allow treatment of larger parts or many more smaller parts per batch.

Our proprietary, high stability HPS plasma generator is continuously variable over the entire 0-300W power range rather than being limited to discreet levels, delivering much finer control when processing delicate materials.

BENEFITS

Versatility

The base model of each system has a single gas inlet and optional second gas or vapour delivery inlet. The units can be prepared so that either option can be added at a later time if required, ensuring that future requirements can be accommodated without expensive reconfiguration.

Repeatable and Reliable

With precision digital mass flow controllers and integrated pressure gauge, the HPT-300 & 500 models deliver unmatched reliability and repeatability by removing common errors in gas flow and gas type settings which will be familiar to users of equivalent equipment that utilise manual needle valves.

BENEFITS

|

|

SPECIFICATION

Technical Specifications |

||||||

|

HPT-300 / HPT-500 Plasma Treatment Systems |

||||||

|

ENCLOSURE |

||||||

|

Dimensions |

HPT-300 - W 533mm x H 466mm x L 615mm (+50mm on rear for cables) HPT-500 - W 533mm x H 600mm x L 615mm (+50mm on rear for cables) |

|||||

|

Weight |

HPT-300 - ~40kg HPT-500 - ~45kg |

|||||

|

CHAMBER |

||||||

|

Material |

Stainless Steel |

|||||

|

Form |

Rectangular |

|||||

|

Dimensions |

HPT-300 - 200mm W x 200mm H x 320mm L HPT-500 - 240mm W x 240mm H x 405mm L |

|||||

|

REMOVABLE PARTS CARRIER |

||||||

|

Material |

Aluminium |

|||||

|

Material options |

Stainless steel |

|||||

|

Form |

Flat tray |

|||||

|

Options |

Multi-level shelf/electrode |

|||||

|

Dimensions |

HPT-300 - 190mm W x 310mm L, others to suit application HPT-500 - 200mm W x 370mm L, others to suit application |

|||||

|

PLASMA POWER SUPPLY |

||||||

|

Power |

HPT-300 - 0-250W, continuously variable output HPT-500 - 0-300W, continuously variable output |

|||||

|

Frequency |

40 kHz |

|||||

|

PROCESS CONTROL |

||||||

|

Interface |

5.7” Colour TFT with recipe store |

|||||

|

Gas channels |

x1 MFC |

|||||

|

Gas channel options |

x2 MFC or x1 MFC and x1 vapour inlet |

|||||

|

Vent inlet |

x1 |

|||||

|

Vent inlet options |

soft ventilation option |

|||||

|

Connections |

6mm compression or 1/4" compression |

|||||

|

Process timer |

1sec – 99.59min |

|||||

|

Recipe store |

Stores up to 4 x recipes with individual parameters |

|||||

|

Pressure gauge |

Pirani sensor |

|||||

|

Vacuum pump |

6 to 15 m3/hr pumping speed |

|||||

|

Vacuum pump options |

2-stage rotary pump (air/inert gas), PFPE rotary pump (oxygen compatible), dry pumps. All pumps include exhaust filter and connections |

|||||

|

SERVICES |

||||||

|

Electrical |

90-250 VAC, 50-60Hz, 1200-1500 VA (including pump), fused 6.3 A T / 10 A T |

|||||

|

Power cord |

Suited to region |

|||||

|

Compliance |

CE – UKCA - ROHS - WEEE |

|||||

|

**Henniker strive for continuous improvement and specifications are subject to change without notic |

||||||