한 레이어에 36개의 시편을 로딩 할 수 있는 2개의 레이어를 가진 Stackable Auto Loader가 장착된 Sundy SDCHN536 CHN Analyzer는 스틸 플랜트, 환경 산업, 발전소, 야금, 석유 화학 산업, 탄광, 석탄, 코크스, 식품, 고형 폐기물, 토양, 비료 등의 탄소, 수소 및 질소 함량을 측정하는 데 사용할 수 있습니다.

Highlights

High Automation.

- Autoloader with 36 positions (72 optional),samples can be added or replaced in the process of testing.

- Automatic sample introduction and testing,realize to work unattended.

Short Thermostatic Time and High Test Efficiency.

- Independent and accurate thermostatic control for analyzer and sensor unit,thermostatic time only need 90 minutes.

High Precision.

- Sample introduction component adopted air curtain design,it can prevent the air into the furnace.and auxiliary by flow equalize unit,guarantee the sample combustion completed,avoid sample splashing when drop,ensure the test result is accurate.

- Adopted high-performance and precision IR sensor to testing the carbon and hydrogen element,and monitoring the combustion situation in real time,competently assess the combustion completion,shorten the test time and obtain a high precision test result.

- With high sensitivity and ultra low temperature drift diffusion type thermal conductivity cell,independent and accurate thermostatic control,ensure the thermal conductivity baseline stable.

Short and Reliable Gas Path.

- Adopted confluence board to integrated the gas path,low dead volume,short gas path and less water vapor residue,accurate and automatic flow control,gas path reliability improved.

Humanized Design, Easy to Operate.

- Easy and convenient to check the air tightness, operators only need to click on the software.

- Replace the crucible from the top of the analyzer,easy to change the furnace reagent and disassemble the furnace body.

Low Operation Cost.

- High stability IR sensor can get stability in short time,adopted throttling device,the helium consumption is only 0.7L/min during sample testing and 0.05L/min at other time.more efficiency than competitor and saving operation cost.

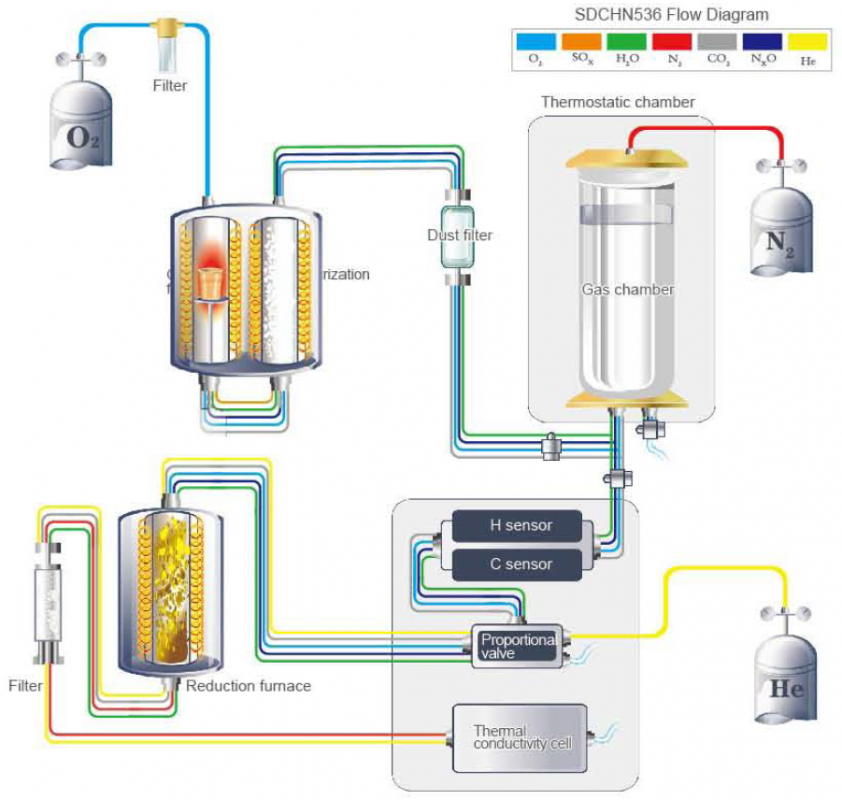

Process Diagram

SDCHN536 Carbon Hydrogen & Nitrogen Analyzer is used to analysis the carbon, hydrogen and nitrogen content in coal or other substances.

A complete sample analysis by SDCHN536 consists of three steps: gas circuit purging, combustion and analysis. First, the operator will put samples into the sample placing tray in sequence. Then input parameters, and Click on "Start test". The system will analyze the carbon, hydrogen and nitrogen content in the sample automatically under specified procedures. Finally, result will be displayed on the interface.

In the combustion process, sample is delivered into the combustion tube for oxygen-excess combustion. Gases generated shall be carried into reagent tube for secondary combustion and desulphurization. After multi-stage filtration, the gases will be collected in the gas collection chamber.

During the analysis process, the combustion gases collected in the gas collection bottle will be mixed completely and then flow into the CO2 infrared sensor, H2O infrared sensor and the proportional chamber. After the gas is stable and balanced, the carbon will be detected by the CO2 infrared sensor in the form of CO2; and the hydrogen will be detected by the H2O infrared sensor in the form of H2O. Gases in the proportional chamber will firstly be carried by helium over heated copper for elimination of oxygen and transform of nitrogen oxides to N2. The carbon dioxide, moisture will be absorbed by alkali asbestos and dehydrite. Then the gas will be introduced to the thermal conductivity cell to detect the nitrogen content.

The final results will be shown on the main interface window in percentage.

Specifications

|

Description

|

SDCHN536

|

|---|---|

|

Measuring Range

|

C: 0.005%~100%

H: 0.01%~50%

N: 0.01%~50%

|

|

Reproducibility

|

Cd≤1.00%

Hd≤0.25%

Nd≤0.15%

|

|

Repeatability

|

Cad≤0.5%

Had≤0.15%

Nad ≤ 0.08%

|

|

Auto loader

|

36/72 Samples

|

|

Analysis time

|

≤ 5min/Sample

|

|

Sample Mass

|

75 ~ 105 mg(Recommended:100 mg)

|

|

Analysis Method

|

CH:Infrared Absorption

N:Thermal Conduction

|

|

Combustion Supporting Gas

|

Oxygen Purity:≥99.5% Pressure:≥1MPa

|

|

Carrier Gas

|

Helium Purity:≥99.99% Pressure:≥1MPa

|

|

Driving Gas

|

Nitrogen / Dry Compressed Air Pressure:≥1MPa

|

|

Preheating Time

|

< 2.5 hour

|

|

Sample Adding/Replacing Function

|

Available

|

|

Auto Analysis

|

Yes

|

|

Crucible Replacing

|

Automatic

|

|

Furnace Temperature

|

Combination Furnace,950 ℃ ±5℃

Reduction Furnace:700 ℃ ±5℃

|

|

Air Tightness Detection

|

Automatic

|

|

Humidity

|

20% to 85%, non-condensing

|

|

Ambient Temperature

|

15 ℃ to 28 ℃

|

|

Power requirement

|

220 V(-15%~10%)50/60Hz

|

|

Max.Power

|

3 kW

|

|

Dimensions

|

680 x 640 x 996 mm

|

|

Weight

|

160 kg

|

|

Advance Calculation

|

Yes

|

|

Analysis Report

|

Yes

|

|

Statistics Report

|

Yes

|

|

System Monitor

|

Yes

|

|

Standards

|

AS 1038.6.4, ASTM D5373, ASTM D5291, ISO 16634, ISO 16948, ISO 29541, EN 15407,EN ISO 16948:2015-0, UNI 15104, UNI CEN/TS 15407

|

|

Options

|

SDCH536, SDC536, SDH536, SDN536

|

Sundy SDCHN536 Carbon Hydrogen & Nitrogen Analyzer can be used to determine the carbon, hydrogen and nitrogen content in coal,coke,food,solid wastes,soil,fertilizer,etc in the fields of power plant,coal mine,metallurgy,petrochemical industry,steel factory environmental industry and so on.

Stackable auto loader, 36 samples per layer,2 layers with 72 samples available