Different Shapes of Sputtering Targets

(주)연진에스텍은 Planar (flat) Target과 Rotary (cylindrical) Target, Circular Target 및 Ring Target 등 대부분의 증착 공정에 부합하는 다양한 형태의 스퍼터링 타겟을 제공하며, 타겟 크기의 커스터마이즈가 가능합니다.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.

Tungsten Carbide-Nickel Target (WC-Ni)

Tungsten Carbide-Nickel Product Description

The Tungsten Carbide-Nickel Target (WC-Ni) is a composite material renowned for its outstanding mechanical strength, wear resistance, and thermal and chemical stability. Tungsten carbide serves as the primary phase, offering exceptional hardness (typically above 1600 HV) and high melting points exceeding 2700°C, making it suitable for high-energy sputtering environments. Nickel acts as a metallic binder, enhancing the composite’s ductility and toughness while maintaining excellent corrosion resistance.

Produced through advanced processes like hot isostatic pressing or vacuum sintering, the WC-Ni target features a dense microstructure with minimal porosity. This ensures high sputtering efficiency and uniform thin film deposition. Depending on the WC:Ni ratio, the electrical resistivity ranges between 10-20 µΩ·cm, and the thermal conductivity remains high, aiding in effective heat dissipation during deposition. The material maintains structural integrity under both mechanical and thermal stress, making it ideal for demanding sputtering applications where consistent target performance and film quality are paramount.

Tungsten Carbide-Nickel Applications

- Hard Coatings: Ideal for creating durable coatings on tools, machinery parts, and cutting surfaces to enhance wear resistance and extend component lifespan.

- Wear-Resistant Coatings: Utilized in industries such as mining, aerospace, and automotive for depositing films on parts subjected to high friction and abrasive wear.

- Protective Coatings for High-Temperature Environments: Applied to components exposed to extreme temperatures and harsh conditions, like engine parts and industrial machinery, to protect against wear and oxidation.

- Decorative Coatings: Provides excellent finish and resistance to wear and corrosion for aesthetic and durable coatings.

- Sputter Deposition: Used in sputter deposition techniques to manufacture thin films with enhanced mechanical strength, hardness, and wear resistance.

Tungsten Carbide-Nickel Packaging

Our WC-Ni Targets are carefully packaged to ensure their integrity during transportation and storage. Depending on the size, smaller targets are securely placed in polypropylene (PP) boxes, while larger targets are shipped in custom wooden crates. We prioritize customized packaging solutions and use appropriate cushioning materials to guarantee maximum protection.

Packaging Options:

- Carton

- Wooden Box

- Customized Packaging

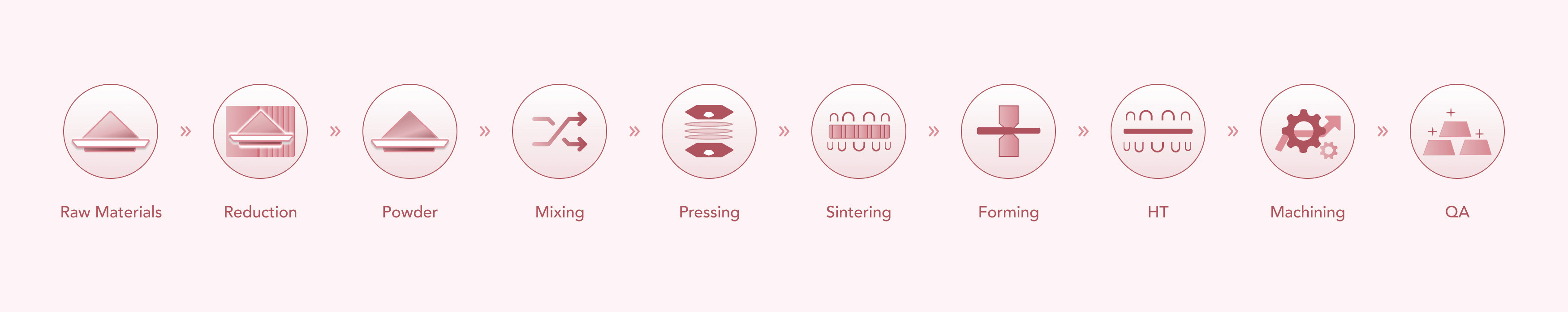

Manufacturing Process

Manufacturing Workflow

Testing Methods

- Chemical Composition Analysis: Verify purity and compositional accuracy using techniques such as Glow Discharge Mass Spectrometry (GDMS) or X-ray Fluorescence (XRF).

- Mechanical Properties Testing: Assess tensile strength, yield strength, and elongation to determine material performance.

- Dimensional Inspection: Measure thickness, width, and length to ensure compliance with specified tolerances.

- Surface Quality Inspection: Detect defects such as scratches, cracks, or inclusions through visual and ultrasonic examinations.

- Hardness Testing: Evaluate material hardness to confirm uniformity and mechanical reliability.

Frequently Asked Questions

Q1: What is a Tungsten Carbide-Nickel Target (WC-Ni Target)?

A1: The Tungsten Carbide-Nickel Target (WC-Ni) is a composite sputtering material composed of tungsten carbide (WC) combined with a nickel binder. It is primarily used in sputtering processes to deposit hard, wear-resistant coatings on various substrates.

Q2: Why combine Tungsten Carbide with Nickel in WC-Ni Targets?

A2: Tungsten carbide provides exceptional hardness and wear resistance, while nickel acts as a binder to improve the material’s toughness, ductility, and corrosion resistance. This combination results in a durable target suitable for extreme conditions.

Q3: What are the benefits of using WC-Ni Targets?

A3: WC-Ni targets offer excellent hardness (above 1600 HV), high melting points (over 2700°C), superior wear resistance, thermal stability, and corrosion resistance. These properties make them ideal for demanding sputtering applications and industries requiring tough, long-lasting coatings.

Performance Comparison: WC-Ni vs. Competitors

|

Property |

WC-Ni Target |

TiN Target |

Pure W Target |

|---|---|---|---|

|

Purity |

≥99.95% (sintered-agglomerated powder) |

≥99.9% (CVD synthesis) |

≥99.99% (high-purity) |

|

Density |

6.2-6.5 g/cm³ (95% theoretical density) |

5.4-5.6 g/cm³ (~92%) |

19.3 g/cm³ (pure tungsten) |

|

Hardness |

54 Rockwell C (limited by porosity) |

2,000-2,400 HV |

350-400 HV (annealed) |

|

Thermal Stability (°C) |

Stable up to 600°C (oxidizes to WO₃/NiWO₄) |

≤700°C (oxidation) |

>1,000°C (excellent stability) |

|

Electrical Conductivity |

Moderate (Ni matrix provides conductivity) |

Semiconducting (~10⁻²-10² S/cm) |

High (~1.8×10⁷ S/m) |

|

Thermal Conductivity (W/m·K) |

20-25 |

19-24 |

173 W/m·K |

|

Mechanical Strength (MPa) |

Flexural strength: ~300 (improved via HIP) |

400-500 |

1,000-1,200 (high ductility) |

|

Oxidation Resistance |

Forms WO₃/NiWO₄ above 600°C |

Forms TiO₂ above 600°C |

Forms WO₃ above 500°C |

Raw Materials

Tungsten (W)

Physical Properties:

- Atomic Number: 74

- Density: 19.25 g/cm³

- Melting Point: 3,422°C

- Structure: Body-Centered Cubic (BCC)

- Hardness: 7.5 on the Mohs scale

Chemical Properties:

Tungsten is a dense, hard metal known for its highest melting point among metals at 3,422°C. It is highly resistant to corrosion and oxidation, even at elevated temperatures. Tungsten’s exceptional hardness and electrical conductivity make it ideal for applications requiring durability and performance under extreme conditions.

Industrial Applications:

- Lightbulb Filaments: Utilized for their high melting points.

- Aerospace Components: Provides strength and durability.

- Armor-Piercing Ammunition: Offers high density and hardness.

- Cutting Tools: Enhances wear resistance.

- Industrial Machinery: Used in parts requiring high durability.

- Electronics and Medical Applications: Includes radiation shielding and electronic components.

Carbon (C)

Physical Properties:

- Atomic Number: 6

- Density: Varies by allotrope (e.g., graphite: 2.267 g/cm³, diamond: 3.51 g/cm³)

- Melting Point: Sublimes at ~3,500°C

- Structure: Allotropes include graphite, diamond, and carbon nanotubes

Chemical Properties:

Carbon is a versatile non-metal element essential in forming strong covalent bonds within carbides. In the WC-Ni target, carbon enhances hardness, wear resistance, and thermal stability. Carbon-based materials like graphene also offer high electrical conductivity and strength, making carbon indispensable in various technological applications.

Industrial Applications:

- Energy Storage: Utilized in batteries and supercapacitors.

- Electronics: Forms the basis of components like graphene and carbon nanotubes.

- Materials Science: Essential for creating high-performance composites.

- Coatings and High-Temperature Environments: Provides durability and resistance.

Nickel (Ni)

Physical Properties:

- Atomic Number: 28

- Density: 8.908 g/cm³

- Melting Point: 1,455°C

- Structure: Face-Centered Cubic (FCC)

- Malleability: Highly ductile

Chemical Properties:

Nickel is a silvery-white metal known for its hardness and corrosion resistance. It serves as a crucial element in alloys, enhancing strength, toughness, and resistance to oxidation. Nickel’s ability to form stable oxide layers makes it ideal for coatings that require durability and protection against harsh environments.

Industrial Applications:

- Alloy Production: Integral in stainless steel and superalloys.

- Batteries: Used in lithium-ion and nickel-metal hydride (NiMH) batteries.

- Electroplating: Provides protective and decorative coatings.

- Catalysis: Acts as a catalyst in various chemical reactions.

- Magnetic Materials: Utilized in manufacturing magnets with specific properties.

하기