Substrate Manipulation

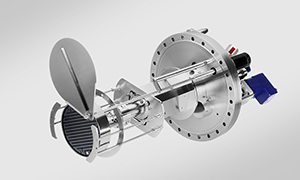

SH, Substrate Manipulators / Deposition Stages

SH substrate manipulators are used in standard III-V MBE, GaN MBE, SiC growth and SiGe MBE. Heaters made from tungsten, tantalum, graphite and SiC are available.

- Uniform heating of substrates from small samples to 6 inch wafer diameter

- Wafer temperatures up to 1200°C

- Heater materials: Tungsten, Tantalum, Graphite, Silicon Carbide, Platinum, PBN encapsulated

- Special heaters for oxygen and reactive gas atmosphere

- Water-cooled ceramic bearings for continuous rotation

- Full adaptability to sample transfer by user-specific linear travel and custom sample holders

- Option for masked deposition:

- transferable wafer mask stage

SH-O, Oxygen Resistant Substrate Manipulator / Heated Station

Using SiC or noble metal heaters, MBE-Komponenten offers substrate manipulators and heated stations that are resistant to oxygen or other corroding atmospheres.

- Oxygen resistance option of the SH substrate manipulator

- Substrate temperatures up to 700°C with Ni-alloy heater; up to 900°C with noble-metal-alloy heater

- up to 900°C with SiC heater depending on oxygen partial pressure

- Pressure range from UHV up few mbar oxygen

- Water cooled ceramic bearings for continuous rotation

- Substrate sizes up to 6 inch

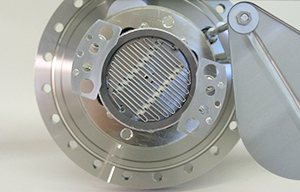

WH, Wafer Heater / Sample Heater / Heated Stages

The wafer heaters or heated stations - WH - are suited for all substrate heating applications where the full functionality of a substrate manipulator is not required.

- Tungsten, tantalum, SiC or graphite heaters

- Wafer temperatures up to 1200°C

- Clean operation and high reliability

- Substrate sizes from 1" up to 6"

- Oxygen resistance and customized solutions possible

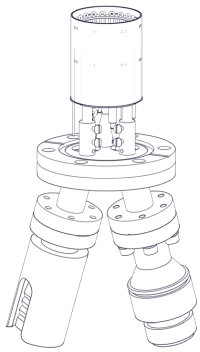

WH40, Loadlock Heater

Main purpose of the Loadlock Heater WH 40 is the controlled heating of both chamber walls and substrates within a loadlock under ultra-high vacuum conditions.

- Tantalum or Tungsten heater

- Wafer or chamber temperatures according to setup (~400°C)

- Clean operation and high reliability

- Suitable for substrate sizes from 1" to 6"

- Customized solutions possible