Valved Sources

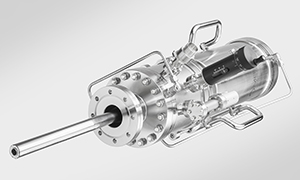

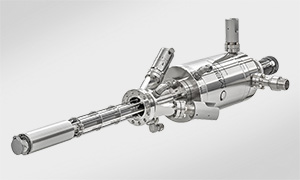

VACS Valved Arsenic Cracker Source

The Valved Arsenic Cracker Source is designed for high performance growth of III-V materials and combines large crucible capacity with precise and fast flux control.

- Compatible with all MBE systems

- Crucible capacity 300 cm³, 500 cm³ or 2000 cm³

- Large valve opening

- Precise and very fast flux control

- Easy handling and refilling procedure

- Integrated water cooling shrouds

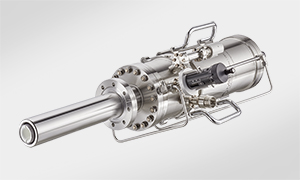

VGCS Valved GaP Compound Source

The Valved GaP Compound Source VGCS is a high purity P2-source, based on the decomposition of high purity GaP.

- Produces pure P2 species (P2/P4 > 150)

- Fast, stable and reproducible flux control

- Large crucible capacity of 420 cm3

- Safe cell loading and operation

- Reliable large cross section cone valve

- No hot cracker zone

- Injector length and flux distribution adjustable to fit most MBE systems

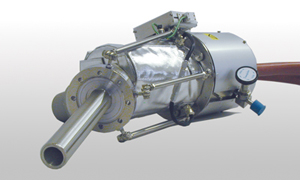

VCS Valved Sulfur Cracker Source

The VCS is a valved sulfur cracker, employed in high efficiency CIS solar cell growth and other II-VI semiconductor material deposition applications.

- Provides cracked or uncracked sulfur flux

- Suitable for other materials like Cs, Pb, K as well (modifications on request)

- Flux modulation and on/off control by motorized valve

- Source capacities from 300 up to 9600 cm³

- Water-cooled assembly

- Excellent flux uniformity due to beam shaping nozzle

- Avoids loss of sulfur during system bakeout

VSCS Valved Selenium Cracker Source

The VSCS is a valved Selenium cracker source, employed in high efficiency CIGS solar cell growth and other II-VI semiconductor material deposition processes.

- Provides cracked or uncracked selenium flux

- Flux modulation and on/off control by motorized valve

- Source capacities from 300 up to 9600 cm³

- Water-cooled assembly

- Excellent flux uniformity due to beam shaping nozzle

- Avoids loss of selenium during system bakeout

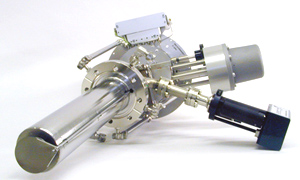

VCCS Valved Corrosive Material Cracker Source

The Valved Corrosive Material Cracker Source VCCS is designed for controlled injection of radicals of antimony, tellurium, magnesium or other corrosive materials in standard MBE applications.

- Evaporation and cracking of Sb, Te, Mg, and other corrosive materials

- Large crucible capacity of 420 cm³

- All PBN construction of valve and cracker stage

- Fast, stable and reproducible flux control

- Easy installation and refilling procedure

- Injector length and mounting flange adjustable to fit most MBE systems

AKS Valved Alkali Metal Source

The Valved Alkali Metal Source AKS is designed for evaporation of elemental high vapor pressure alkali metals like Cs and Rb in standard MBE or UHV systems.

- Compatible with most MBE systems

- Large capacity 150 cm3 evaporator

- Ideal source for Cs and Rb evaporation

- Easy and safe refilling procedure

- Precise and very fast flux control

HGS Valved Mercury Evaporation Source

The Valved Mercury (Hg) Evaporation Source HGS is designed for evaporation of elemental mercury in standard UHV or MBE systems.

- High throughput of up to 60g Hg/h

- Large capacity 250 cm3 evaporator

- 3000 cm3 (40kg Hg) equalizing tank

- Larger capacity on request

- Easy and safe refilling procedure

- Compatible with most MBE systems

VSS Valved Sulfur Source

The Valved Sulfur Source VSS aims at R&D applications where valve controlled small or medium flux rates of high vapor pressure materials are required.

- Provides sulfur flux rates for R&D applications on a DN40CF flange

- Flux regulation and on/off control by motorized valve

- UHV-tight valve

- Water-cooled cracker with beam shaping nozzle

- 12 cm³ or 150 cm³ reservoir

- Reservoir and valve are located ex vacuum

VTCC Valved Thermal Cracker Cell

- Full PBN solution for corrosive materials like Te, Sb, Se, As, Zn and Mg

- DN40CF (O.D. 2.75") mounting flange compatible with all MBE systems

- Thermal cracking up to 1300°C

- 130 cm3 PBN reservoir

- Excellent thermal isolation between low temperature reservoir and hot cracking zone

- Integrated water cooling for cracker stage

- Integrated rotary shutter (optional)