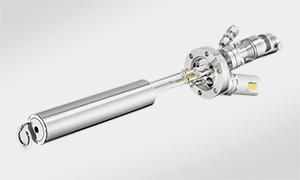

OME Organic Material Effusion Cell

The patented Organic Material Effusion Cell OME was specially designed for the evaporation of volatile organic substances at operating temperatures up to 300°C.

- Patented Thermal Conduction Cooling (TCC)

- Ideal for evaporation of sensitive organic materials in UHV and OLED applications

- Temperature range 15-300°C

- Fast and precise temperature control < ±0.02K with excellent temperature stability

- Crucibles capacities 2 cm³, 10 cm³ and 35 cm³

- Full UHV and MBE compatibility

OEZ Organic Material Effusion Cells

Thermal evaporators of the OEZ type are dedicated to the controlled evaporation of all kind of volatile organic materials.

- Controlled evaporation of volatile organic materials in research and industry

- Fabrication of OLED and organic photovoltaic cells, or spintronic devices

- Precise deposition with no temperature overshoot (stability to ±0.05K)

- Operating temperatures 50 - 700 °C

- 2 to 8-fold cluster arrays are offered for co-deposition processes

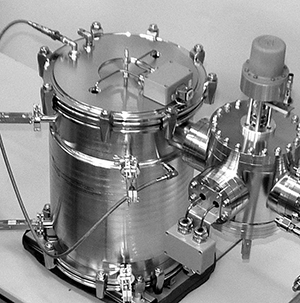

OEZ-Cluster Organic Material Effusion Cell Cluster

The OEZ-Cluster Sources offer two/four effusions cells on a single flange, designed for controlled evaporation of all kind of volatile organic materials.

- Controlled evaporation of volatile organic materials in research and industry

- Fabrication of OLED and organic photovoltaic cells, or spintronic devices

- Precise deposition with no temperature overshoot (stability to ±0.1K)

- Operating temperatures 50 - 700 °C

- 2 to 8-fold cluster arrays are offered for co-deposition processes

Industrial Point Sources

The OEZ-Cluster Sources offer two/four effusions cells on a single flange, designed for controlled evaporation of all kind of volatile organic materials.

- Flange size DN 100 ISO-K

- Patented Thermal Conduction Cooling (TCC)

- Ideal for evaporation of organic materials

- for PV, display and OLED applications

- Fast and precise temperature control

- Temperature range 15-400°C

- Fully UHV and MBE compatibility

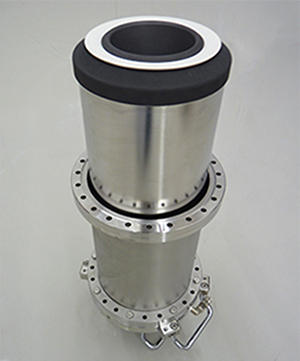

Thermostar

The Thermostar is a Cu crucible inset for reduction of temperature gradients of organic evaporants.

- Cu inset for reduced temperature gradients in the organic source material

- Au, Ag or other coating on request

- Flexible design to fit various crucibles

- Temperature range 15-700°C

PEZ-G Production Scale CIGS Evaporation Source

- Large capacity up to 55 kg Cu

- Very high flow rate up to 220 g/h for Cu

- Long lifetime

- Designed for easy maintenance

- Proprietary encapsulation of heater and shielding

- Simple ingot handling

- High material efficiency through beam shaping insert

- Encapsulated thermocouple

- Pyrometeric temperature control option

- Well proven in the field

LES Production Scale Linear Evaporation Source

- Large capacity up to 6000 cm³

- High flow rate

- Long lifetime

- Propriatary encapsulation of heater and inner shielding

- Excellent homogeneity due to beam shaping nozzle design

- Encapsulated thermocouple

- Evaporation zones up to 220 cm width

PVSS Production Scale Valved Selenium and Sulfur Source

- Reservoir Volume 9600 cm³, larger volume on request

- Pneumatically actuated normally closed valve

- Easy refill

- Optimized for fast maintenance

- Robust heater design

- Water-cooled assembly

- Option for carrier gas version

Depending on the type of organic material which you want to deposit you may select the evaporation source by our selection guide by organic material below.

Our organic evaporators are specially designed for use with volatile organic materials. They are applied both in research and in industrial deposition processes.

The small version of the Organic Material Effusion Cell (OME) is dedicated for use in research applications where only small quantities of sensible organic evaporants are loaded with a sublimation temperature below 300°C. It OME allows fast heating and cooling which makes it an ideal source for expensive organic material evaporation.

For materials with typical evaporation temperatures above 200°C up to 700°C we recommend our Organic material effusion cell (OEZ). This source is also available as various clusters with two, 4 or more cells on one mounting flange with shutters quartz monitors etc.

For high capacity industrial applications like OLED or solar cell fabrication we offer large versions of the OME and the OEZ as well as large capacity linear sources. Please contact us for more detailed information.

Selection by Organic Material

|

Material |

Chem.Formula/ CAS number |

Tevap [°C] |

Source |

Application |

|---|---|---|---|---|

|

Tris-(8-hydroxyquinoline) aluminum (Alq3) |

C27H18AlN3O3 |

~ 150 low flux |

OLED research |

|

|

> 300 high flux |

OLED industrial |

|||

|

Fullerene (C60) |

C60 |

~ 225 low flux |

cosmetics, organic PV and reserach |

|

|

> 300 high flux |

||||

|

Fluorinated fullerene |

C60F48 |

~ 110 |

research |

|

|

3,4,9,10-Perylenetetracarboxyldiimid (PTCDI) |

C24H10N2O4 |

~ 200 |

dye and reserarch |

|

|

Melamin |

C3H6N6 |

~ 80 |

resin, plastics, and research |

|

|

Perylen |

C20H12 |

~ 95 |

dye, OLED, and organic PV |

|

|

Pentacene |

C22H14 |

~ 220 |

OFET and research |

|

|

Chloro[subphthalocyaninato] boron(III) |

C24H12BClN6 |

~ 150 low flux |

CD-R and research |

|

|

> 250 high flux |

The table contains general recommendations without warranty.