Although many reactions run better when catalysed it is very difficult to know the best catalyst to use.

A recent survey of catalyst manufacturers suggested that in excess of 1000 versions of alumina supported platinum exist.

This raises questions. Which is the best system? What are the best conditions?

The ability to measure both kinetics and thermodynamics simultaneously allows users to select the parameters which are important to their process and monitor those as the catalyst is changed.

High pressure vessels (up to 10bar) now available with the Micro Reaction Calorimeter allow gas phase reactions (e.g. hydrogenation) to be examined.

The μRC can be supplied with a high pressure transducer for direct measurement of gas uptake during reaction or gas evolution measurement.

Our μRC-Pro, dedicated kinetics package gives users the ability to easily import data directly into a specialist kinetics analysis software and then to model the reaction using a wide range of purpose designed systems. μRC-Pro is compatible with the CISP software products which allows full-scale models of reactions to be implemented for reactor modelling, runaway prediction and other useful parameters.

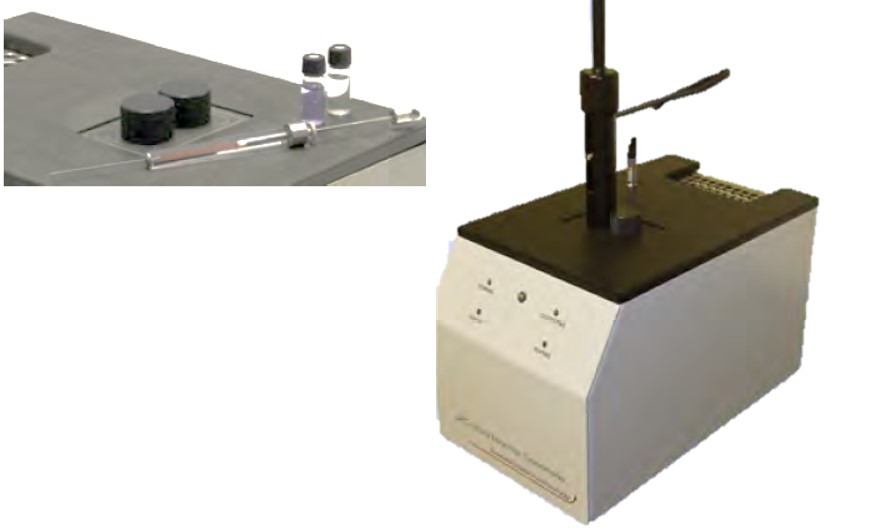

The THT Micro Reaction Calorimeter (µRC™) has a wide range of applications in the chemical, pharmaceutical and related fields. This brochure shows how using a microcalorimeter can help chemists and engineers in everyday tasks.

Some of the applications detailed within this brochure include:

- Reaction Kinetics

- Process Development

- Scanning Calorimetry

- Thermal Stability

- Heat Capacity Measurement

- Adhesive Curing Reactions

- Waste Management

- End Point Determination

- Hazard Analysis

All chemical, physical and biological reactions are accompanied by heat change. These reactions, though sometimes subtle, can be measured using calorimetry. This powerful analysis method works without modification of the sample or process. The THT Micro Reaction Calorimeter is based on power compensation technology making it faster in both signal response and temperature variation. Designed for maximum flexibility, the µRC has the capability to measure both kinetic and thermodynamic parameters in both rapid and slow reactions and in solids, liquids or gases. Measurements made by calorimetry are non-destructive and non-invasive making it valuable for initial analyses and for systems where other techniques fail. With the µRC there is minimal sample preparation and no limitation on the physical state of the material. Systems can be studied under ambient or modified environmental conditions.

Specification

- Baseline Noise: From 5μW

- Dynamic Range: 5μW to 600mW

- Temperature Range: -5°C to 170°C

- Standard Modes of Operation: Isothermal/Titration/ Scanning

- Optional Modes: Pressure - pressurise cell up to 10bar

uRC에 의한 촉매 선별 (Catalyst Screening by uRC) - Scanning Rate: Up to 2°C/min

- Isothermal Stability: +/- 0.0001°C over extended time period

- Cell Volume: 1.5 ml

- Cell Type: Removable glass vial

- Injection Volume: 1 to 250 μl

- Temperature Control: Peltier based (no external cooling)

- Stirring Speed: 0 - 400 rpm

- Measurement Principle: Power compensation

- Connection to PC: via USB cable

- Footprint (width x depth x height): 19 x 31 x 35 cm

- Certain other specifications may be possible by discussion