열량계는 시멘트 재료의 수화 작용으로부터 생성된 열을 측정합니다. 측정된 온도 그래프의 모양 및 피크점 위치등의 정보는 시멘트 혼합물의 상대적인 활동성과 혼합물간 반작용을 시각적으로 보여줍니다.

Calmetrix사의 단열열량계 (Semi-Adiabatic Calorimeter)인 F-Cal 시리즈는 휴대용 열량계로써 연구소뿐만 아니라 야외 현장에서도 전력공급 없이 최대 36시간 동안 사용할 수 있도록 만들어졌습니다. 최대 1.57 L의 샘플 측정이 가능한 4개 또는 8개의 채널로 구성되어 있습니다. 예를 들면, F-Cal 단열열량계는 콘크리트 혼합물의 비율 또는 새로운 첨가제에 대한 품질관리 및 리서치에 사용될 수 있습니다.

- Type of instrument: Semi-adiabatic Calorimeter

- Number of test channels: 8

- Suitable for mortar or concrete, conforms to ASTM C1753

Examples of use:

-

Mix designs

-

Troubleshooting (incompatibility of materials)

-

Inbound quality control of raw materials

-

Quick estimation of setting time

-

Portable diagnostics and troubleshooting instrument for admixture, cement or fly ash field technicians

F-Cal 8000 is a handy, portable calorimeter with eight sample channels that emulates the curing conditions of concrete flatwork. It is ideal for quick testing of concrete in field conditions.

F-Cal units are portable, yet rugged enough to be carried in the back of a pick-up truck, or left on site in a Concrete plant for testing in real conditions.

F-Cal 8000 enables testing of up to eight cement, mortar or concrete simultaneously, in standard 3"x6" (75 mm x 150 mm) cylinders or in any container of equal or smaller size. Calmetrix's proprietary CalCommander software for data retrieval and analysis lets users to select one of the F-Cal's cells as a temperature reference cell.

F-Cal 8000 is recommended for testing in field conditions for up to 36 hours (*) and does not require a dedicated computer or a power source. The equipment is battery operated and stores data logged for up to 7 days. Heat curves obtained can be interpreted almost instantaneously by the user, or stored and sent in a report to an off-site QC Manager.

Example of use:

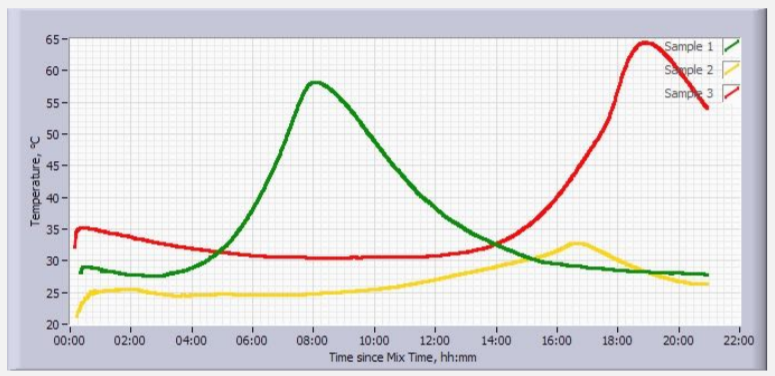

adverse material interaction (Applicable Instruments: any F-Cal or I-Cal instrument)

This example shows a potential adverse interaction. The green curve shows a normal Portland cement mix with 25% of a low calcium fly ash. The red curve is the same mix, with a retarder and a mid-range water reducer (brand A) at normal doses. The setting time is severely retarded, but the curve does not show any other adverse interaction. The yellow curve has the same retarder as in the red curve, but a water reducer of a different brand (“brand B”). The curve shows severe interaction, with no strength gain. The combination of fly ash, and retarder is not compatible with the “brand B” water reducer.

Example of use:

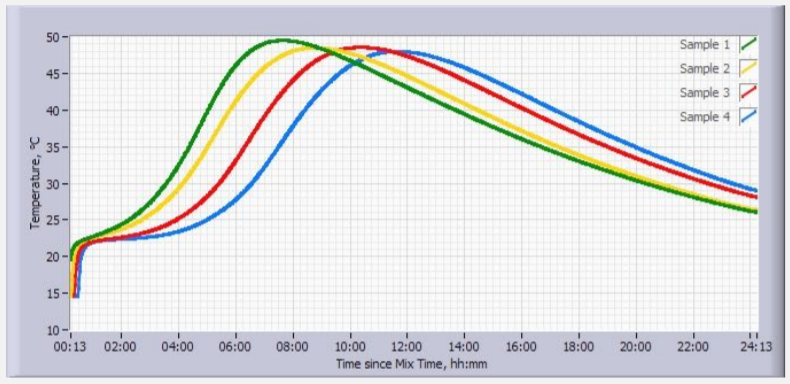

optimum admixture dosage (Applicable Instruments: any F-Cal or I-Cal instrument)

This example shows the effect in a given mix of gradually increasing dosage of a retarder. The progression shown in this example is a close-tolinear response to dosage, Differences in setting times can easily be inferred in the F-Cal calorimeter, with the blue curve setting 3 hours and 30 minutes after the green curve. The same test could be conducted with different cements to select the one that provides the most robust and predictable response to dosage increases. A common test is also to look at the effect of different admixture addition (upfront, with water or delayed).

Example of use:

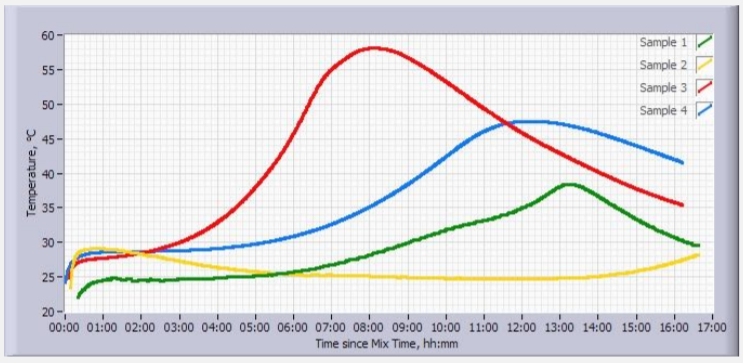

maximize cement substitution (Applicable Instruments: any F-Cal or I-Cal instrument)

This example shows the effect of a cement substitution by a high-calcium fly ash,. The red curve is a 100% Portland cement mix. The blue curve is the same mix with 12% substitution by fly ash, the green curve has 17% substitution and the yellow curve 22%. The calorimetry curves reflect the increase in setting time (curves shift to the right) and lower reactivity (lower peaks) leading to a decrease in early strength. In this test, the green curve shows that 17% is very close to a “danger zone”. 22% substitution will severely retard the mix, with no strength gain after one day.

F-Cal 8000's main applications are:

- on-site troubleshooting for material incompatibility (e.g. admixtures that do not work well for certain cement sources)

- quick estimation of setting times

- rapid screening of materials, e.g. different sources of cement, different brands of admixtures

- robustness test (how performance holds up to variations in material dosages)

- mix design optimization

(*) For improved signal-to-noise ratio and longer test periods up to 28 days or longer, see the Calmetrix P-Cal 1000 high performance calorimeter.