Precise nanoparticle generation and analysis

Crafting precise coatings using Charged Nanoparticles

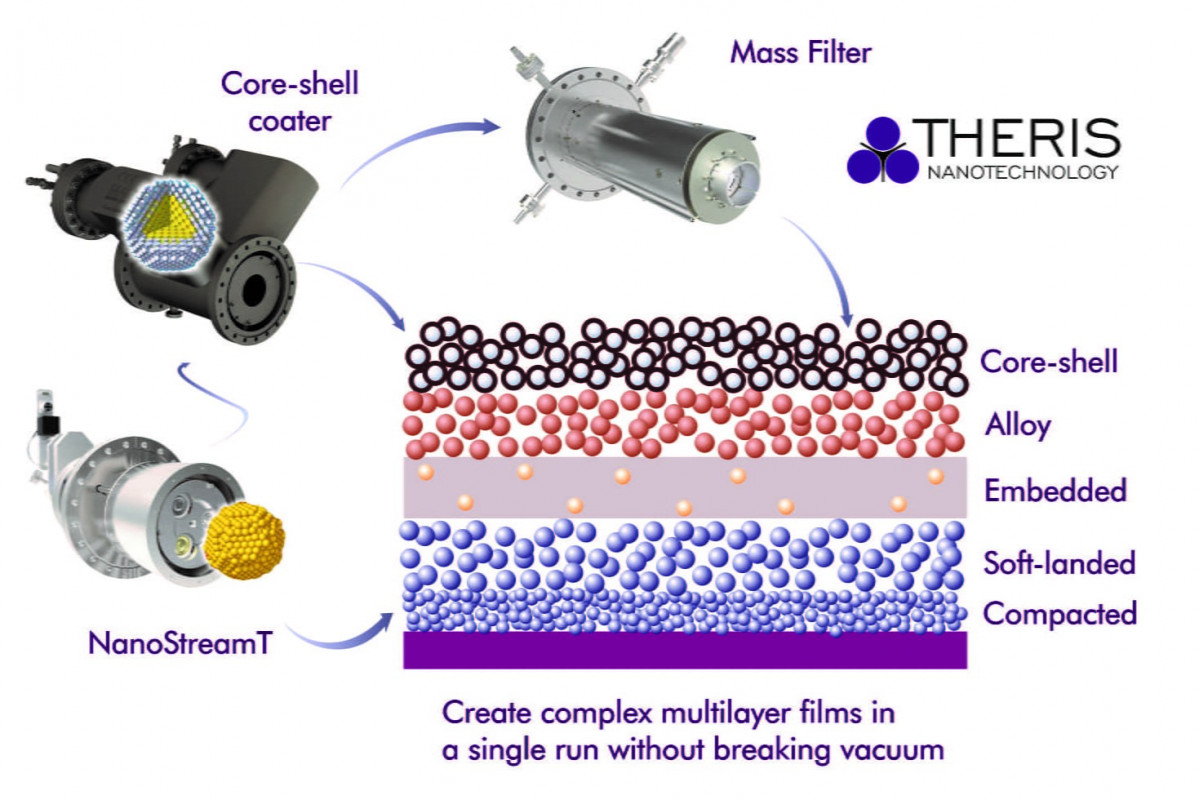

NANOPARTICLE COATING SOURCES

Theris Nanotechnology offer a wide range of UHV Nanoparticle deposition equipment.

Designed with total user control in mind, enabling the creation of ultra pure and size selected nanoparticle films and the additional options of creating alloy and core-shell nanoparticles. The custom software allows simple control of cutting edge and complex process.

NANO PARTICLE PRODUCTION METHOD

ULTRA-PURE NANOPARTICLES

Gas condensation of size-selected Nanoparticles in vacuum for contaminant-free films

In the Theris NanoStreamS and NanoStreamT sources the nanoparticles are produced by a ‘terminated gas condensation’ method. In this technique, a DC magnetron is used to sputter target material. The sputtered atoms enter the high pressure condensation zone where their mean free path becomes very small and they quickly thermalise. Nanoparticles are formed as these thermalised atoms migrate towards the expansion zone.

The NPS generated by this method tend to possess one additional (negative) electronic charge and this allows them to be electrostatically manipulated either through deflection, focusing or acceleration. The acceleration towards the substrate allows the particle impact energy to be controlled precisely. At low acceleration (<<1eV per atom) the particles soft-land without deformation. At higher energies they undergo a small degree of interface mixing and form a highly porous layer of bound nanoparticles. At very high energy the particles fuse to revert to bulk material. Such nanoparticle manipulation produces a wide variety of coating morphologies from nanoparticle powder, through porous films with an exceptionally high surface area to crystalline structures.

The gas flow characteristics within the condensation zone ensures refinement of size distribution of the beam to allow precise definition of the particle size in the emergent beam. The unique configuration of the condensation zone also maximises the ratio of nanoparticles to carrier gas entering the main deposition chamber. Nanoparticles can be generated with as few as 30 atoms up to those with diameters close to 20 nm.

TAILORED COMPOUND NANOPARTICLE SYNTHESIS

NanoStreamT

Triple-head source for compound nanoparticles

The NanoStreamT is operated in the same way as the NanoStreamS, but uses an internal sputter source with three independent targets, enabling the user to form compound nanoparticles. By varying the respective power applied to the three targets, the composition of the nanoparticles can be tailored to explore the properties of alloy and compound nanoparticles.

PRECISE SIZE SELECTION

The Nanostream sources, in isolation, produces a beam of nanoparticles with a well-defined size distribution, typically +/- 20% at FWHM. The mean diameter can be varied from just 30 atoms to those with diameters approaching 20nm (material dependent) which represents a huge variation in mass. The size of the nanoparticles can be determined and further refined with the use of the optional QNF quadrupole mass filter specifically designed for high-mass particles.

ULTIMATE NANOPARTICLE ANALYSIS

QNF Mass Filter

Mass measurement and filtering of nanoparticles

The QNF quadrupole mass filter can be used in line with the NanoStream sources to analyse and further filter the nanoparticle beam with throughput up to 10 amu. The quadrupole has an ultimate size resolution of 2% filtering mode, allowing precise particle size definition to be achieved. It is supplied as standard with software control for analysis from a windows-based PC.

PRECISE SIZE SELECTION

The QNF mass filter can be used in line with the NanoStream sources to analyse and further filter the nanoparticle beam with throughput up to 10^6 amu. The quadrupole has an ultimate size resolution of 2% filtering mode, allowing precise particle size definition to be achieved. The mass filter can also be equipped with deflection and focus electrodes to allow manipulation of the beam post-filtering. It is supplied as standard with software control for data capture and subsequent analysis from a windows-based PC.

ADVANCED NANOPARTICLE GENERATION

FROM BATTERY ELECTRODES TO CNT GROWTH

NANOPARTICLE APPLICATIONS

The unique method of nanoparticle generation, which allows pure films of size-selected nanoparticles to be deposited, lends itself to a wide array of applications which cannot be accomplished using chemically-grown or self-assembled nanoparticles. The additional feature of using acceleration to tailor the density of the films, adds another layer of control over the films and further broadens the range of applications.

- Alloy nanoparticles

- Core-shell particles

- Ultra-pure, size-selected particles

- Compacted nano-porous films

NANOSTREAM SOURCES APPLICATIONS

The extreme purity, size-selection and ability to electrostatically manipulate the nanoparticles produced by the NanoStream sources gives rise to a wealth of applications including:

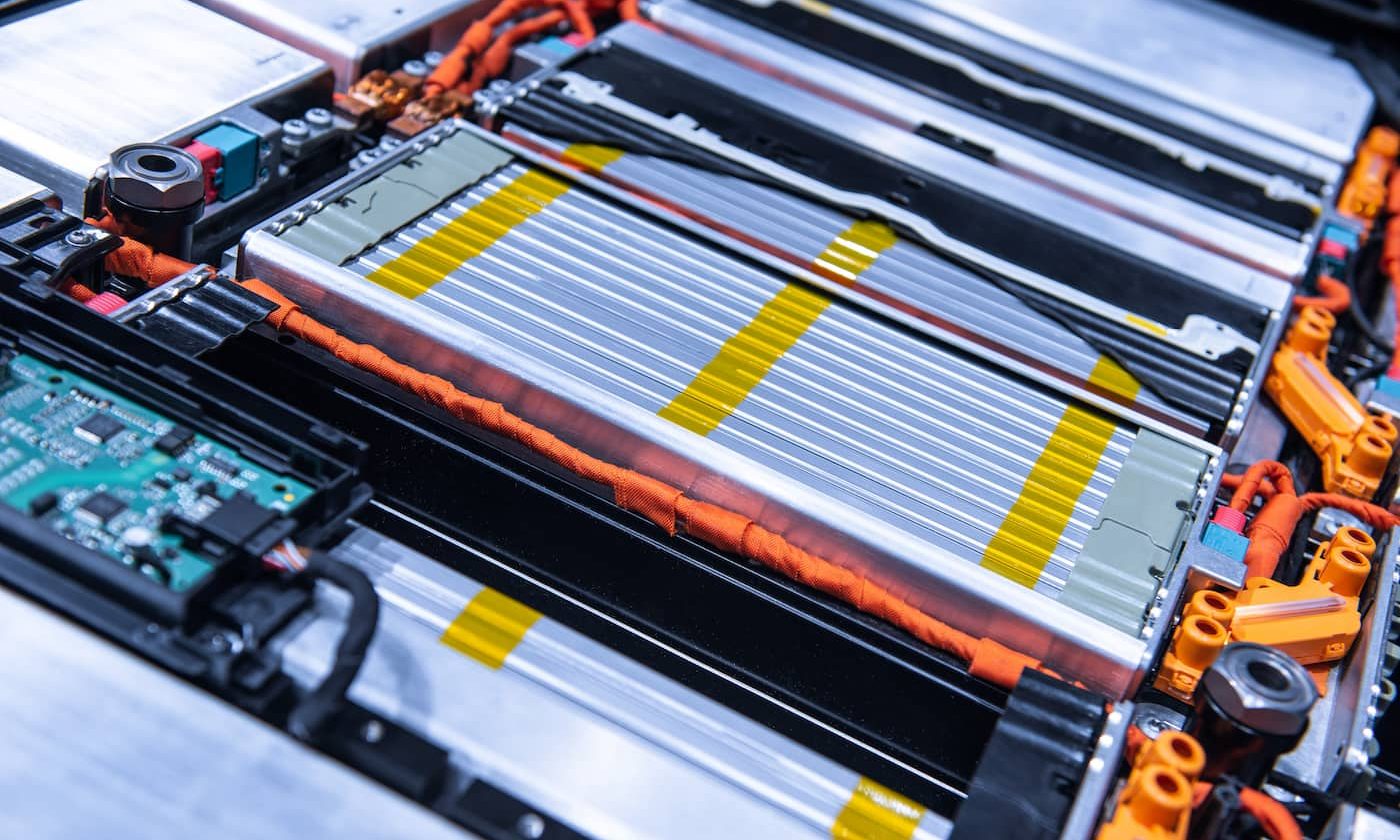

- Nanostructured battery electrodes

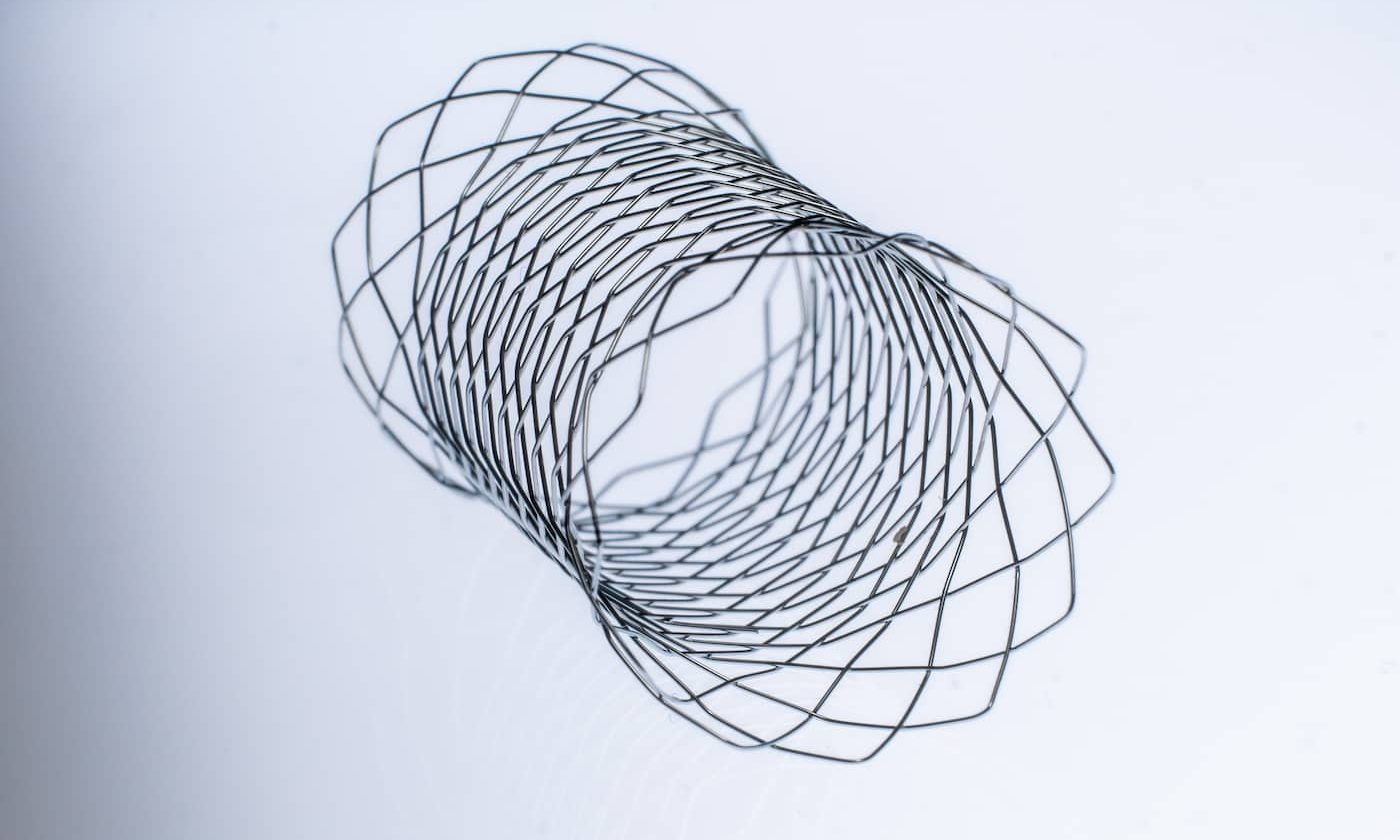

- Porous films for medical devices or selective filters

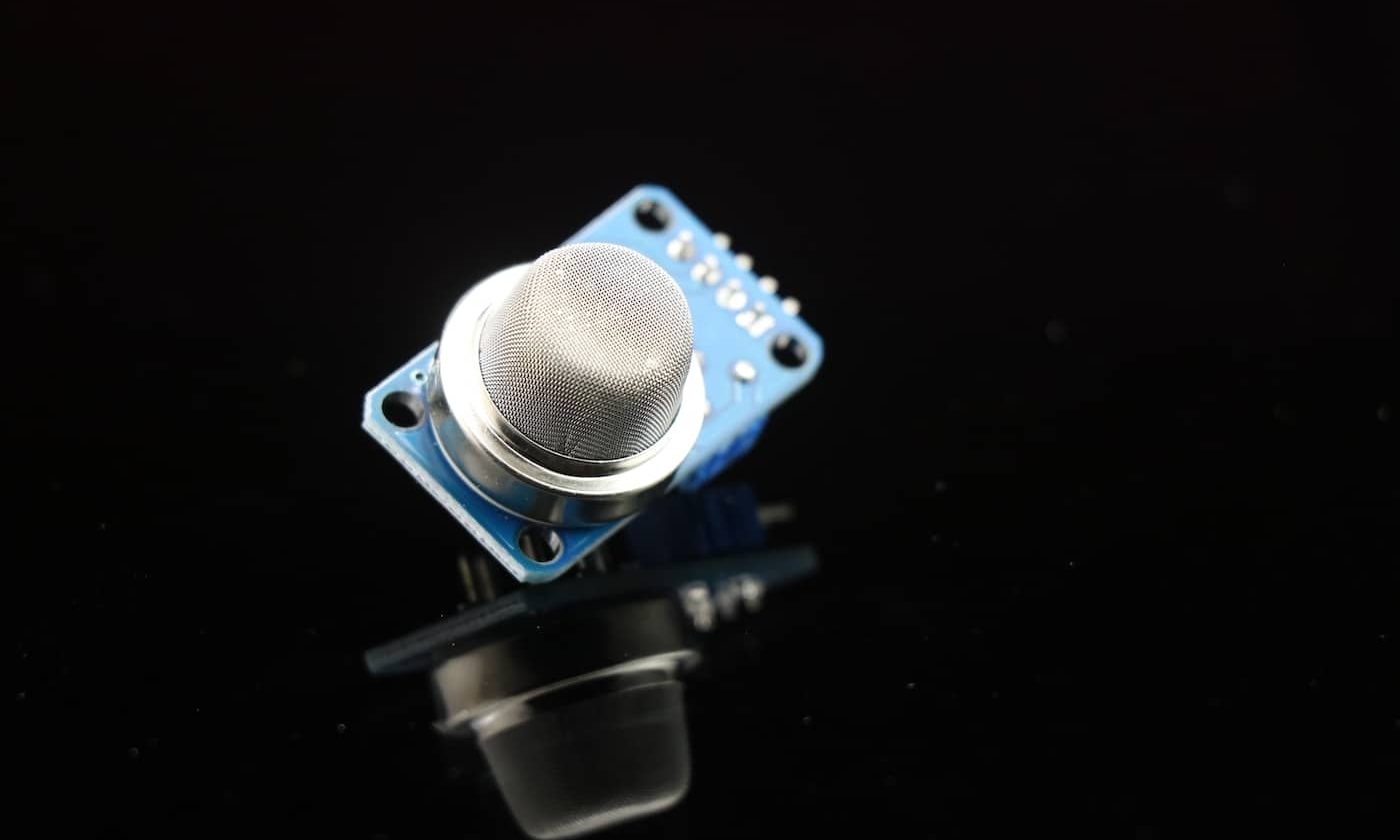

- Highly specific gas or liquid sensors

- Catalytic surfaces with vast surface area

- Fuel Cell research

- Photovoltaic films

- Seeding layers for nanowire or CNT growth

하기