Different Shapes of Sputtering Targets

(주)연진에스텍은 Planar (flat) Target과 Rotary (cylindrical) Target, Circular Target 및 Ring Target 등 대부분의 증착 공정에 부합하는 다양한 형태의 스퍼터링 타겟을 제공하며, 타겟 크기의 커스터마이즈가 가능합니다.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.

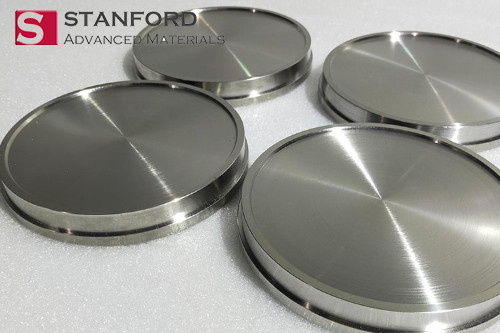

Cobalt Chromium Molybdenum Target (CoCrMo Target)

Description of Cobalt Chromium Molybdenum Target (CoCrMo Target)

The CoCrMo Target is a high-strength, corrosion-resistant sputtering material renowned for its outstanding mechanical integrity and chemical stability. This ternary alloy leverages the unique properties of cobalt, chromium, and molybdenum to deliver exceptional performance under extreme conditions. Cobalt forms the primary matrix, providing excellent wear resistance, high-temperature strength, and inherent toughness. Chromium enhances corrosion resistance by creating a stable, passive Cr₂O₃ oxide layer that safeguards the material against oxidation and chemical attacks in both acidic and oxidative environments. Molybdenum contributes to the alloy’s strength at elevated temperatures, increases hardness, and boosts resistance to pitting and crevice corrosion, particularly in chloride-rich or reducing settings.

The microstructure of CoCrMo is typically refined using powder metallurgy or vacuum melting techniques, resulting in a dense, homogeneous material with controlled grain size and minimal porosity. The alloy boasts a high melting range (approximately 1300-1400°C, depending on the composition), moderate thermal conductivity, and a coefficient of thermal expansion compatible with common substrate materials, ensuring stability during sputtering processes. Its moderately low electrical resistivity makes it suitable for producing uniform thin films. Overall, the CoCrMo Target exhibits excellent thermal, mechanical, and chemical properties, making it highly reliable for precise and stable deposition processes.

Specifications of Cobalt Chromium Molybdenum Target (CoCrMo Target)

Properties:

- Chemical Composition: Co, Cr, Mo

- Purity: 99.95%

- Shape: Planar Disc

Please note: The information provided is based on theoretical data. For specific requirements and detailed inquiries, contact us directly.

Size

Customized to meet your specific needs.

Applications of Cobalt Chromium Molybdenum Target (CoCrMo Target)

-

Biomedical Coatings: Widely used for orthopedic and dental implants due to its excellent biocompatibility, wear resistance, and corrosion resistance in body fluids, enhancing the longevity and functionality of prosthetic devices.

-

Aerospace & Turbine Components (Protective Films): Applied as thin films on engine parts and turbine blades to improve surface durability, thermal resistance, and performance in high-stress, high-temperature environments.

-

Microelectronics & MEMS Devices: Suitable for magnetic thin films and microelectromechanical systems (MEMS) thanks to its stability and moderate electrical resistivity, which are critical for maintaining mechanical integrity and corrosion resistance.

-

Wear-Resistant Coatings: Utilized in industrial tools, cutting instruments, and sliding components to provide superior hardness and abrasion resistance in chemically or mechanically aggressive environments.

-

Chemical Processing Equipment Surface Engineering: Protects surfaces in valves, reactors, and pumps exposed to corrosive or erosive chemical flows, requiring both mechanical strength and corrosion resistance.

Packaging of Cobalt Chromium Molybdenum Target (CoCrMo Target)

Our CoCrMo Targets are packaged in customized cartons tailored to the dimensions of the material. Smaller items are securely packed in polypropylene (PP) boxes, while larger items are placed in custom wooden crates. We prioritize packaging customization and use appropriate cushioning materials to ensure optimal protection during transportation.

Packaging Options:

- Carton

- Wooden Box

- Customized Packaging

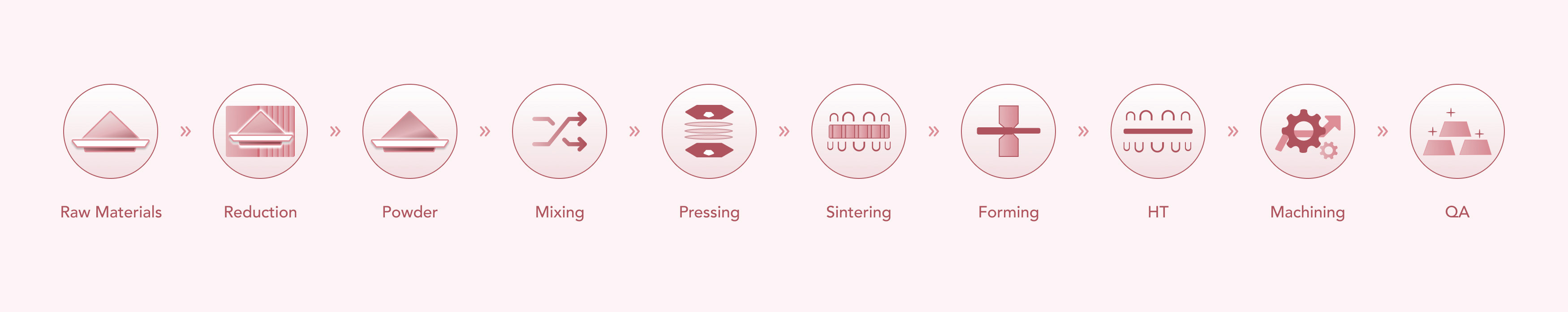

Manufacturing Process

Overview of Manufacturing Process

Testing Methods

- Chemical Composition Analysis: Verified using techniques such as Glow Discharge Mass Spectrometry (GDMS) or X-Ray Fluorescence (XRF) to ensure purity requirements are met.

- Mechanical Properties Testing: Includes tensile strength, yield strength, and elongation tests to assess material performance.

- Dimensional Inspection: Measures thickness, width, and length to ensure adherence to specified tolerances.

- Surface Quality Inspection: Checks for defects like scratches, cracks, or inclusions through visual and ultrasonic examination.

- Hardness Testing: Determines material hardness to confirm uniformity and mechanical reliability.

FAQs about Cobalt Chromium Molybdenum Target (CoCrMo Target)

Q1: How are your CoCrMo targets manufactured?

A1: We utilize vacuum arc melting and/or powder metallurgy techniques combined with hot isostatic pressing (HIP) to achieve high density, low porosity, and excellent compositional homogeneity.

Q2: What sputtering methods are compatible with CoCrMo targets?

A2: CoCrMo targets are compatible with both Direct Current (DC) and Radio Frequency (RF) magnetron sputtering systems. Process parameters may vary based on film thickness and substrate material.

Q3: Can you provide custom sizes or shapes for the target?

A3: Yes, we offer a wide range of customization options, including planar, circular, rectangular, and rotary targets, with additional options for backing plates and bonding services.

Performance Comparison: CoCrMo Target vs. Titanium Target vs. Stainless Steel Target

|

Specification |

CoCrMo Target |

Titanium Target |

Stainless Steel Target |

|---|---|---|---|

|

Composition |

Co, Cr, Mo |

Ti |

Fe, Cr, Ni, Mo |

|

Hardness |

High hardness and wear resistance |

Moderate hardness |

Moderate to high hardness, depending on alloy composition |

|

Corrosion Resistance |

Excellent, especially in biological environments |

Excellent in harsh environments |

Good, generally lower than CoCrMo and Titanium |

|

Thermal Stability |

High, suitable for high-temperature applications |

High, ideal for aerospace and medical use |

Moderate, used in industrial and some medical applications |

|

Wear Resistance |

Superior wear resistance |

Moderate wear resistance |

Moderate wear resistance |

|

Biocompatibility |

Highly biocompatible, ideal for medical implants and prosthetics |

Highly biocompatible, commonly used in implants |

Generally biocompatible, varies with alloy (e.g., 316L for implants) |

|

Electrical Conductivity |

Low |

Low, valued for strength and lightness |

Good |

|

Applications |

Medical implants, prosthetics, aerospace components, dental implants |

Aerospace, medical devices (e.g., implants), electronics |

Industrial equipment, medical tools, coatings, aerospace components |

|

Density |

8.3-8.6 g/cm³ |

4.5 g/cm³ |

7.9-8.1 g/cm³ |

|

Melting Point |

1,300°C to 1,400°C |

~1,668°C |

1,400°C to 1,500°C |

|

Typical Purity |

99.5% or higher |

99.9% or higher |

99.9% or higher |

Additional Information

Raw Materials – Cobalt

Physical Properties:

- Density: ~8.90 g/cm³

- Melting Point: 1495°C

- Boiling Point: 2927°C

- Magnetism: Ferromagnetic up to 1115°C (Curie temperature), suitable for magnetic applications

- Appearance: Bright silver-gray with a slight bluish tint; stable in air at room temperature

Chemical Properties:

- Resists oxidation by forming a passive oxide layer in air.

- Exhibits +2 and +3 oxidation states, forming various oxides, chlorides, and sulfates.

- Cobalt compounds are typically strongly colored, such as cobalt blue from CoAl₂O₄.

Industrial Applications:

- Superalloys: Enhances high-temperature strength and oxidation resistance in turbine blades and aerospace components.

- Magnetic Materials: Essential in permanent magnets like AlNiCo and samarium-cobalt used in electronics and motors.

- Batteries: Utilized in lithium-ion battery cathodes (e.g., LiCoO₂) for excellent electrochemical performance.

- Sputtering Targets & Thin Films: Used in thin film deposition for magnetic, wear-resistant, and corrosion-resistant coatings.

Other Features:

- Mechanical Strength: High strength and ductility at both room and elevated temperatures.

- Corrosion Resistance: Good resistance to acids and moisture, ideal for chemically aggressive environments.

- Biological Role: Essential trace element in human nutrition (found in vitamin B₁₂), though elemental cobalt is toxic in excess.

Raw Materials – Chromium

Physical Properties:

- Density: ~7.19 g/cm³

- Melting Point: 1907°C

- Boiling Point: 2671°C

- Hardness: One of the hardest metals (Mohs hardness ~8.5), providing excellent wear resistance

- Appearance: Silvery-gray, brittle metal with high polish and reflectivity

Chemical Properties:

- Highly resistant to oxidation and tarnishing due to the formation of a stable Cr₂O₃ oxide layer.

- Common oxidation states are +3 and +6; Cr³⁺ is more stable and less toxic, while Cr⁶⁺ is a strong oxidizing agent and environmentally hazardous.

- Chromium compounds are known for vivid colors, such as chrome green and chrome yellow, widely used in pigments and dyes.

Industrial Applications:

- Stainless Steel & Alloys: Key component in stainless steel, typically added at ≥10.5% to enhance corrosion and oxidation resistance.

- Protective Coatings: Used in chrome plating and Physical Vapor Deposition (PVD) coatings for tools, automotive parts, and electronics.

- Sputtering Targets & Thin Films: Employed in the production of hard, conductive, and corrosion-resistant coatings for semiconductors, displays, and optical devices.

- Refractory Materials: Utilized in high-temperature ceramics and bricks due to its high melting point.

Other Characteristics:

- Electrical Resistivity: Moderate (~12.9 μΩ·cm), suitable for controlled conductive layers.

- Toxicity: Metallic chromium and Cr³⁺ compounds are generally safe, but Cr⁶⁺ compounds are toxic and regulated.

- Environmental Stability: Forms stable compounds that resist degradation in harsh chemical environments.

Raw Materials – Molybdenum

Physical Properties:

- Density: ~10.2 g/cm³

- Melting Point: 2623°C (one of the highest among metals)

- Boiling Point: 4639°C

- Hardness: High strength and hardness, especially at elevated temperatures

- Thermal and Electrical Conductivity: Good conductor of heat and electricity; thermal conductivity ~138 W/m·K

Chemical Properties:

- Relatively inert in air and water at room temperature.

- Forms stable oxides (notably MoO₃) and is resistant to many acids, especially when alloyed.

- Common oxidation states are +4 and +6, with Mo⁶⁺ being the most prevalent in compounds.

Industrial Applications:

- Alloying Agent: Widely used in steel and superalloy production to enhance strength, toughness, and corrosion resistance.

- Electronics and Thin Films: Key material in sputtering targets for semiconductor interconnects, TFT back electrodes, and solar cells due to its conductivity and adhesion.

- High-Temperature Components: Ideal for furnace parts, filaments, and aerospace components exposed to extreme heat.

- Catalysis: Molybdenum compounds serve as catalysts in petroleum refining and chemical synthesis.

Other Attributes:

- Vacuum Compatibility: Excellent for use in vacuum environments due to low vapor pressure.

- Machinability: While hard, molybdenum can be machined with appropriate tooling and care.

- Biological Role: Trace amounts are essential in human and animal metabolism, involved in enzyme function.

하기