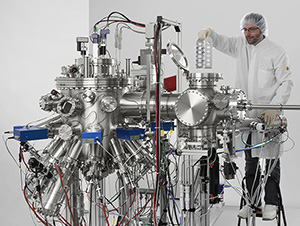

Thin Film CIGS, CZTS or CdTe Solar Cell Systems

OCTOPLUS 500

- Turbo molecular pumped growth chamber with reactive material trap

- Base pressure in 10-10 mbar range, lower on request

- Up to 12 source ports

- Substrate size up to 6 inch, or 100 mm x 100 mm

- large capacity sources for Cu, Ga, In, and for Se

- fast ramping source for Ga and In for sharp composition profile deposition on request

- uniformity of layers better +/-1% in thickness and composition

- Software allows fully automated layer by layer growth with growth recipes, cell ramping data logging. etc.

- Fast entry load-lock with 5-10 samples in a lift-magazine

- The loadlock can be pumped down <10-6 mbar in less than 25min. Base pressure is in the 10-9 mbar range

- This R&D CIGS system is well optimized and has shown excellent results in the field.

Product range and quality of Dr. Eberl MBE-Komponenten GmbH benefit from the many years of active research experience of its team members. We now look back on about 30 years of development and manufacture of complex systems and components for multiple tasks in the applied research and production of compound semiconductor materials. Each product is assembled and carefully tested in-house by our MBE experts.

| The Thin Film system in this category is based on our OCTOPLUS 500 chamber. It is a versatile and very thoroughly designed UHV deposition system, ideally suited for thin film deposition like CIGS, CZTS or CdTe solar cell absorber layer growth.

We provide special large capacity reactive material resistant effusion cells, as well as valved cracker sources for Selenium, Sulfur, CdTe and Te. The substrate manipulator allows well controlled substrate heating and manipulation up to 6 inch diameter or 10cm x 10cm size. The well proven software EpiSoft controls all shutters, cell- and manipulator temperatures, substrate rotation, the chamber pressure and other features. Excellent operation reproducibility and safety is guaranteed. |

View into the deposition system, wafer and port to the deposition chamber are visible |

|

|

The standard version of the OCTOPLUS 500 comprises up to 12 source ports with 4.5 inch (DN 63) and 6inch, (DN 100) flange size. Bellow-free soft-acting linear shutters are offered with very long life-time. The shutters provide 0.2sec open and closing time.A rapidly pump-down load lock chamber with a horizontal working transfer rod system allows easy substrate introduction without breaking the vacuum of the MBE chamber. |

PEZ-W 63-160-60-DF, Selenium resistant deposition source for copper, indium and gallium |

Information about material capacity of the PEZ-W 63-160-60-DF

| density | minimum | maximum | |

| copper | 8,954 g/cm3 | 98 g | 877g |

| indium | 7,31 g/cm3 | 95 g | 819 g |

| gallium | 5,904 g/cm3 | 77 g | 661 g |

The PEZ 63-160 effusion cell is suitable for fast ramping procedures to comparably high deposition rates. With a precise dynamic ramping, the rate profiles of inline deposition systems can be reproduced. Process development and transfer from MBE-like co-evaporation systems to inline production systems become much easier.

A more detailed description you will find in the attached paper (28th EU-PVSEC, 3BV.5.17).

|

VSCS, Valved Cracker Source for Selenium with Valve Controller MVCU and Power Supplies

|