The identiPol QA2 has three modes of operation: Comparison, Confirmation and Identificaon. The Confirmation mode of the system can be used to confirm that a fresh batch or delivery of material from your supplier can be processed without issue.

First the system “learns” the properties of good material - in this case Polypropylene (PP) - by measuring 10 to 20 batches of good material that have previously been processed without problems. These measurements are used to build a reference set against which future batches can be compared against.

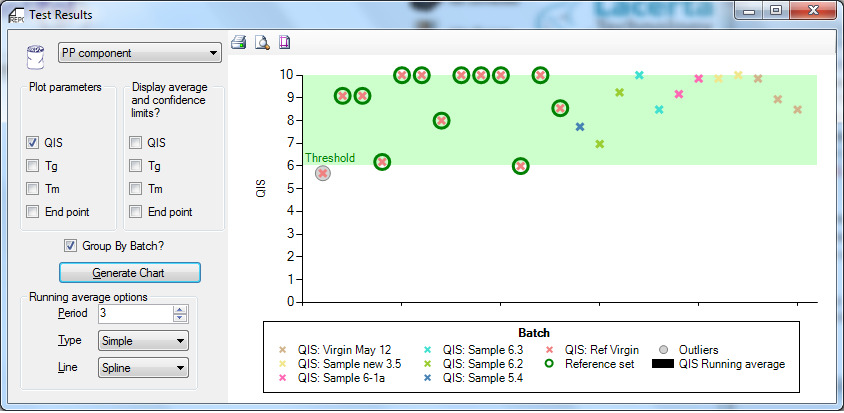

The identiPol system uses the Quality Index Score (QIS) as a measure of similarity between in-coming material and a reference set. A QIS of 10 would indicate that the samples are totally identical and a value of 0 would mean they are completely different. In practice values between 7 and 10 are perfectly acceptable in order to have confidence that the material may be put onto the production line with confidence. The simplicity of using the QIS value as a measure of PASS (7 or over) or FAIL (less than 7) cannot be over emphasised as it enables new, inexperienced or non-technical staff to quickly make a judgement prior to pung material into the manufacturing process.

Test samples are prepared by moulding a couple of plastic granules within the identiPol QA2 to give a consistent material for measurement. This is then followed by a second heating regime to measure the properties of the new batch of material.

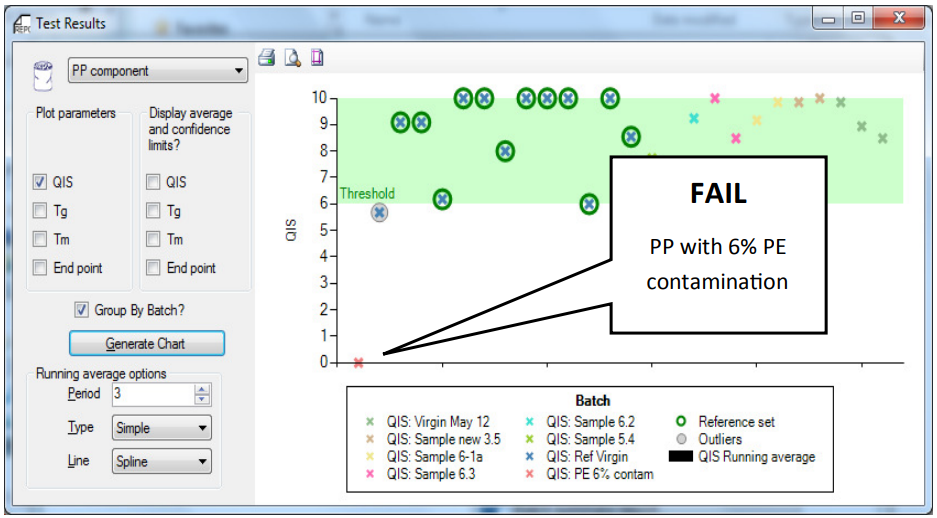

A sample score between 4 and below 7, would usually indicate it is very similar, but a key property (e.g. a lower softening temperature) is different. Contamination is one reason why a QIS value could drop below 7. If there is contamination in sufficient quantity to affect the QIS, then it will almost certainly affect either processing or product properties.

In the example below the QIS value is shown for various samples of a PP component. The consistency of these batches is clear, with average for each batch scoring over 7.

So, within 10-15 minutes of a new delivery, an operator can make a decision about the suitability of accepting and using the fresh material on the production line.

Small levels of contamination can make a large difference to the processability of a material and of the properties of the final moulded part.

A fresh batch of material, contaminated with only 6% of PE (Polyethylene), was then evaluated using the QA2. The QIS value is seen to drop to zero with only a small amount of contamination, illustrating the sensivity of the QA2 to detecting differences between batches of material.

The identiPol QA2 has three modes of operation: Comparison, Confirmation and Identification. The Confirmation mode of the system can be used to confirm that a fresh batch or delivery of material from your supplier can be processed without issue.

First the system “learns” the properties of good material - in this case Polypropylene (PP) - by measuring 10 to 20 batches of good material that have previously been processed without problems. These measurements are used to build a reference set against which future batches can be compared against.

The identiPol system uses the QIS as a measure of similarity between in-coming material and the reference set. A QIS of 10 would indicate that the samples are totally identical and a value of 0 would mean they are completely different. In practice values between 7 and 10 are perfectly acceptable in order to have confidence that the material may be put onto the production line with confidence. The simplicity of using the QIS value as a measure of PASS (7 or over) or FAIL (less than 7) cannot be over emphasised as it enables new, inexperienced or non-technical staff to quickly make a judgement prior to putting material into the manufacturing process.

In the example below the QIS value is shown for various samples of a PP component. The consistency of these batches is clear, with average for each batch scoring over 7.

So, within 10-15 minutes of a new delivery, an operator can make a decision about the suitability of accepting and using the fresh material on the production line.

Small levels of contamination can make a large difference to the processability of a material and of the properties of the final moulded part.

A fresh batch of material, contaminated with only 6% of PE (Polyethylene), was then evaluated using the QA2.

하기