Simulation of the beam distribution of evaporation sources and the deposition of material on a substrate.

Simulation of the material evaporation and deposition in vacuum is usually

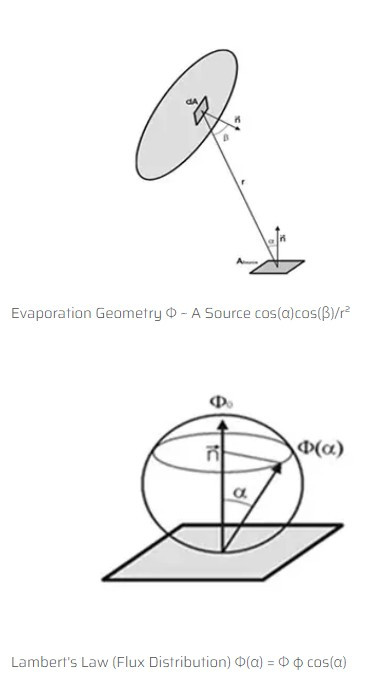

Simulation of the material evaporation and deposition in vacuum is usually based on the fundamental physical laws for the evaporation geometry (1/r2 -Law) and Lambert’s Law, which explain the angular flux distribution from and to a surface element. These allow the application of different concepts to calculate the beam distribution of evaporation sources and therefore the deposition of material on a substrate.

The popular concept of geometrical approximation uses a simplified modell of the evaporation source to calculate the deposition onto a substrate. For certain directions the emitted beam intensity from the source is determined experimentally and fitted to a mathematical function. Often a cosn (α) angular distribution is used for the further calculation of the beam flux distribution on the substrate. Due to the simplifications, the precision of this concept is typically limited to about 5…10%.

For achieving a much better precision of about 1% and better we use the concept of Monte Carlo particle tracing. Starting from the surface of the evaporated or sublimated material the path of several millions of single particles within the source and through the vacuum chamber is tracked until they hit the substrate. Considering the real source geometry (crucible, beam shaper, etc.) allows the precise determination of the angular beam flux distribution on a wide angular range, even for an assymmetric setup.

After calculation of the beam flux distribution on the substrate plane, many other characteristic results can be derived, like layer thickness distribution or material composition for co-evaporation processes assuming stationary or moved substrates (e.g. rotation, linear motion, roll-to-roll deposition or spherical substrates)

|

|

“Particle Ping-Pong” in the Monte Carlo particle tracing concept and example for the resulting beam flux distribution on the substrate |