Dielectric Cure Monitor

LTF-631은 UV 광경화 수지 및 경화속도가 빠른 열경화성 고분자의 경화거동에 관한 R&D, 소재의 품질 보증 / 품질 관리 및 제품 생산 시 수 초 이내로 빠르게 경화하는 재료를 연구하는 데 쓰이는 유전율측정기입니다. LTF-631의 10Hz ~ 10KHz 주파수 범위는 SMC / BMC 및 UV 경화 시스템에 대한 탁월한 감도를 제공하고, 경화 온도와 경화 속도, 재료 특성의 상관 관계를 연구하는 데 효율적입니다. 본 제품을 이용한 경화거동분석에는 주로 Varicon Disposable Variable Conductivity Sensor가 사용됩니다.

- 10 Hz, 100 Hz, 1.0 kHz, 10 kHz의 여기 주파수 (excitation frequency)

- SMC / BMC 및 UV 경화 시 탁월한 감도 제공

- 온도센서를 통해 재료 특성과 경화 속도, 온도 상관 관계 분석

- 최대 4 개의 dielectric channel

- 경화 모니터링 파라미터의 정의

- 일회성 또는 재사용 가능한 dielectric sensor

- CureView 데이터 포집 전용 소프트웨어

The LTF-631 is available with a maximum of four dielectric channels. Each channel consists of one mid-conductivity dielectric sensor input and one thermocouple input. A single-channel instrument may be upgraded at any time with additional channels. In addition to the dielectric channel(s), the LTF-631 has two general analog inputs which may be used for pressure sensors and LVDT signals.

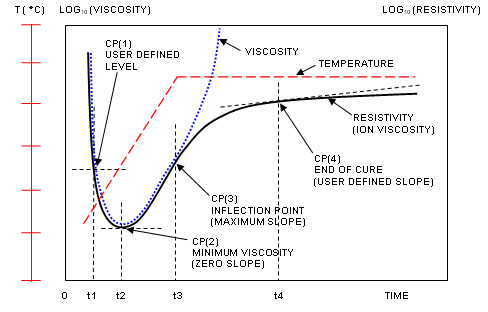

The CureView Data Acquisition Software has functions for defining cure monitoring parameters; data acquisition, analysis and recall; plotting and printing.

When used with either disposable or reusable dielectric sensors, also available from Lambient Technologies, or the user’s own sensors, the LTF-631 High Speed Dielectric Cure Monitor and CureView data acquisition software form a complete measurement system for studying dielectric material properties in all processing environments.

Materials

- Epoxy

- Polyurethane

- Polyester

- Polystyrene

- Composites and laminates

- Bulk molding compound/Sheet molding compound

- Paints and coatings

- Reaction injection molding

- UV curing resin systems

Processing environments

- Ovens

- Presses

- Autoclaves

- Pultruders and extruders

- Batch reaction vessels

Specifications

Measurement:

- Excitation frequencies: 10 Hz, 100 Hz, 1.0 KHz, 10 KHz

- Excitation amplitude: Sine wave, 1.0 V nominal (2.0 V peak-to-peak)

- Maximum sampling rate: 55 milliseconds or better

- Dielectric interface: Maximum of four (4) channels of mid-conductivity with -one (1) dielectric sensor, and one (1) thermocouple per channel

- Instrument inputs: Two (2) start/triggers, and two (2) analog inputs (0 - 5 V range) per instrument, analog inputs may be used for pressure sensor or LVDT with suitable electronic interfacing

- Outputs: Two (2) TTL/digital outputs

- Dielectric sensor type: Interdigitated, parallel plate or single electrode for Mid-Conductivity interfaces

- Thermocouple type: J standard, K by special order

- Number of channels: 1 channel for LT-631/1, 2 channels for LT-631/2

- Communications: RS-232C, USB with adapter

Physical

- Dimensions: 17” W x 16” L x 3.25” H (43.2 cm W x 40.6 cm L x 8.3 cm H), Weight: 16 lbs (7.3 Kg)

- Electrical Power: 100 VAC ? 240 VAC, 50/60 Hz autoswitching universal input, 4 A max

The LTF-631 is designed for the study of rapidly reacting materials in Research & Development, Quality Assurance/Quality Control, and Production applications involving thermoset materials--resins, composites, paints and coatings. The 10 Hz to 10 KHz frequency range of the LTF-631 permits excellent sensitivity for SMC/BMC and UV curing systems, and the associated thermocouple input allows correlation of temperature with cure rate and material properties.