Thermal plate system은 일상적인 연구실 벤치 탑 실험뿐만 아니라 프로빙과 특성분석에 필수적입니다. INSTEC은 수십 년에 걸친 온도 컨트롤 전문 지식을 업계 최고의 thermal plate에 집약시켰습니다. 플레이트는 20mm ~ 300mm 정사각형 표준 샘플링 면적으로 제작됩니다. 600mm 이상의 크기도 커스터마이즈 가능합니다. -190ºC ~ 600ºC (필요 시 최대 1500ºC)의 온도 컨트롤은 ± 0.1ºC 의 온도 분포도와 안정성을 제공합니다. 플레이트는 AFM 및 여러 스캐닝 프로브에 잘 어울립니다. Defrost, gas purge, 또는 vacuum 기능이 있는 씰드 챔버로 전환이 가능한 선택적 커버로 플레이트의 제작이 가능합니다.

BENCHTOP THERMAL PLATES

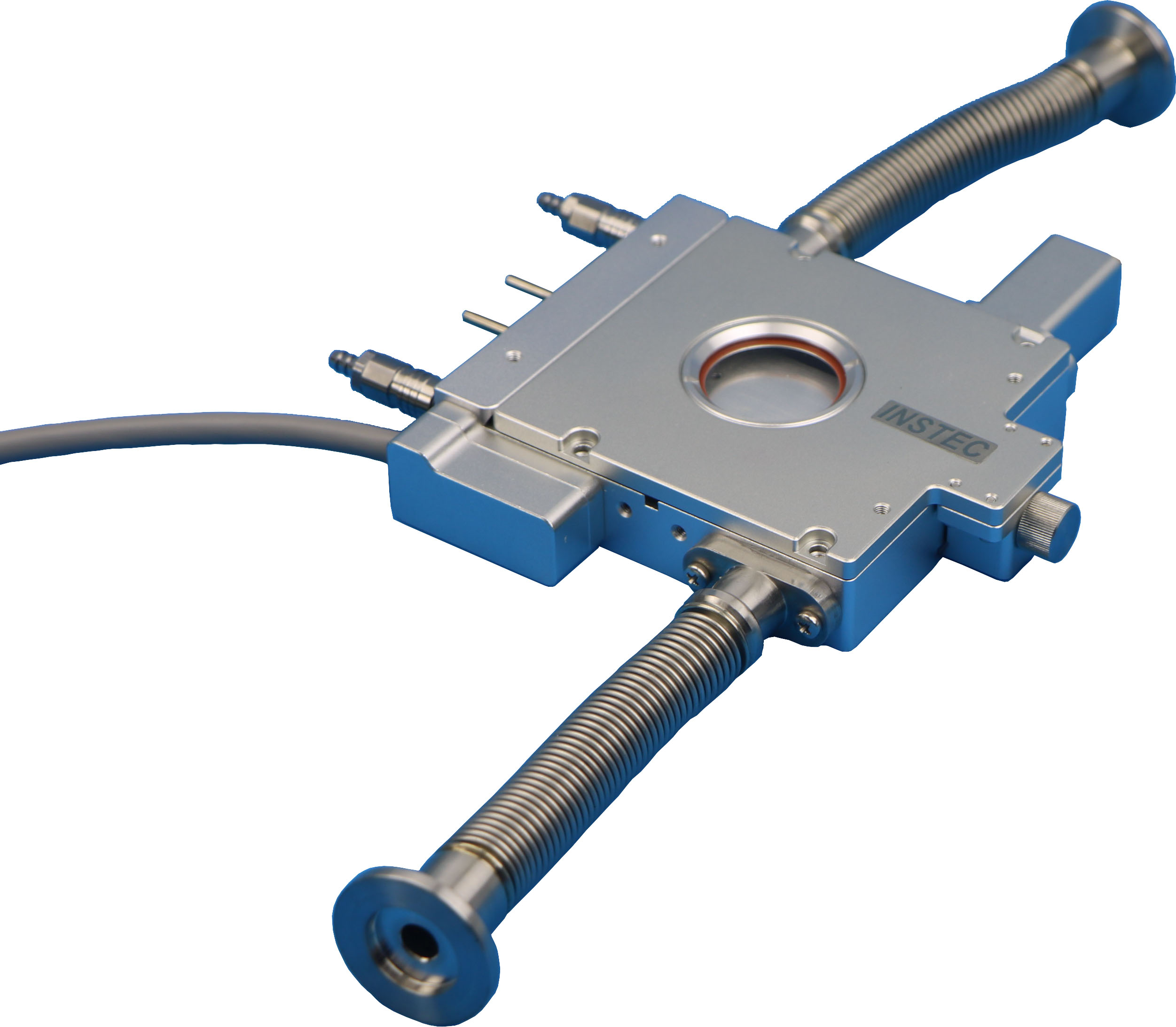

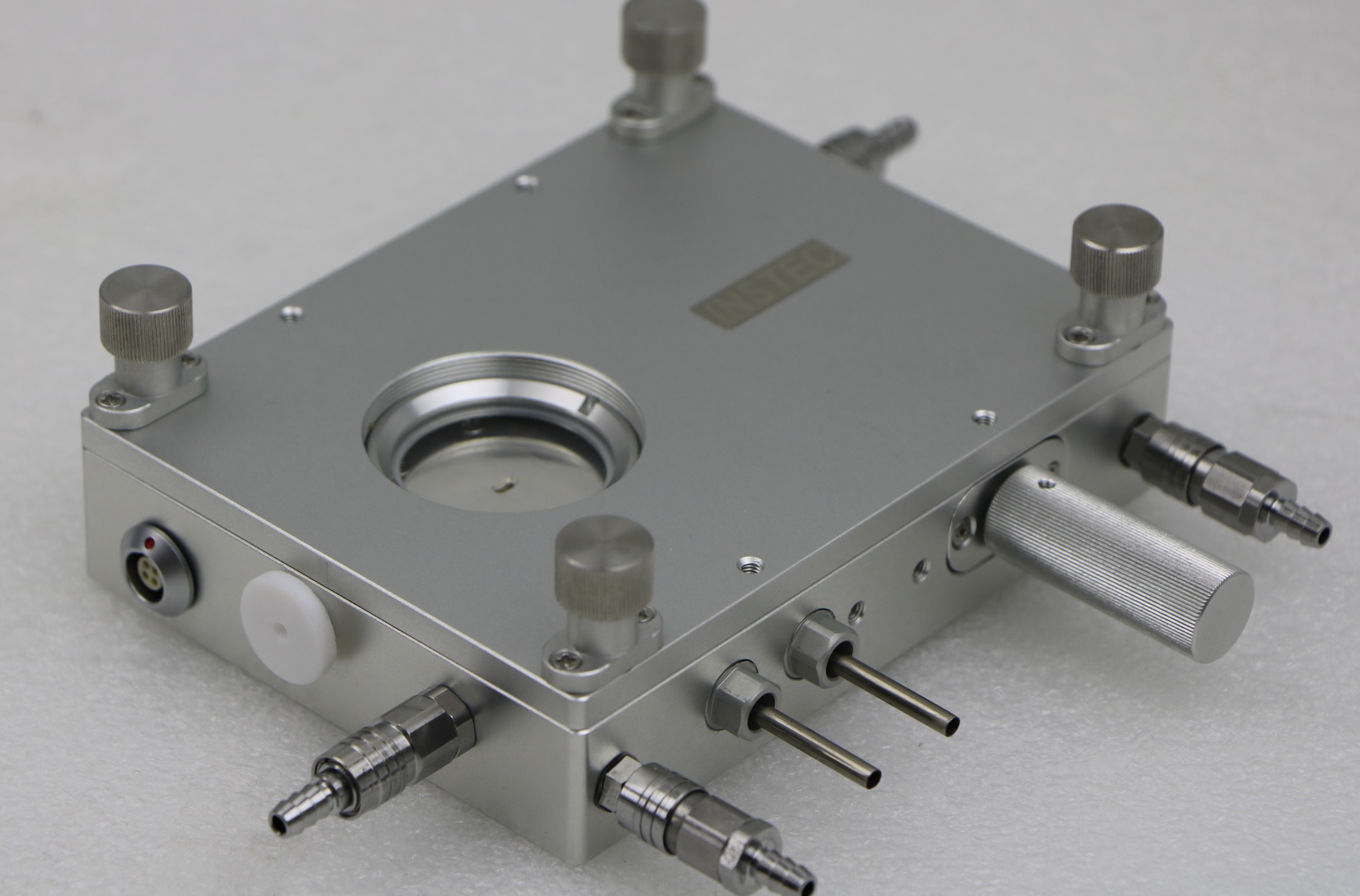

TP 102 / 104 / 106 / 108 / 10C SG Series |

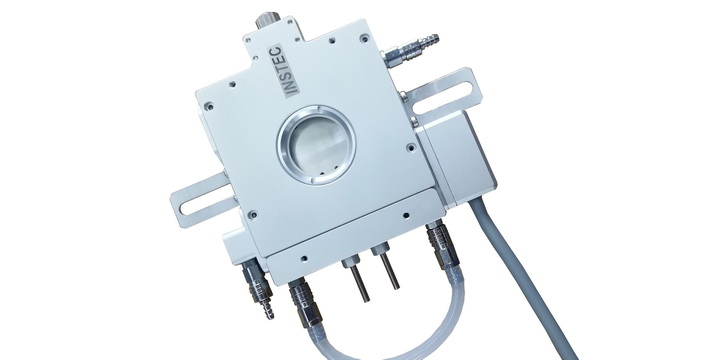

Square Hot and Cold Plates with Gas Tight Covers |

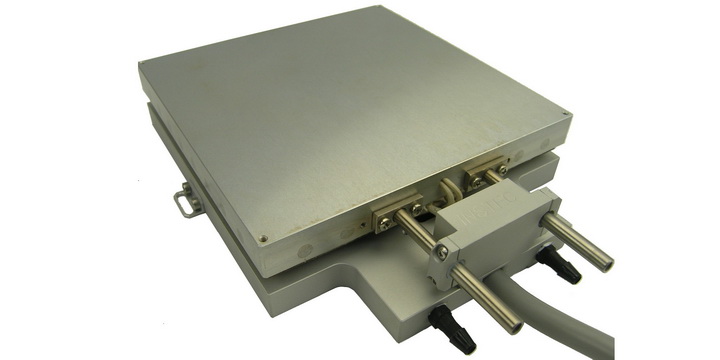

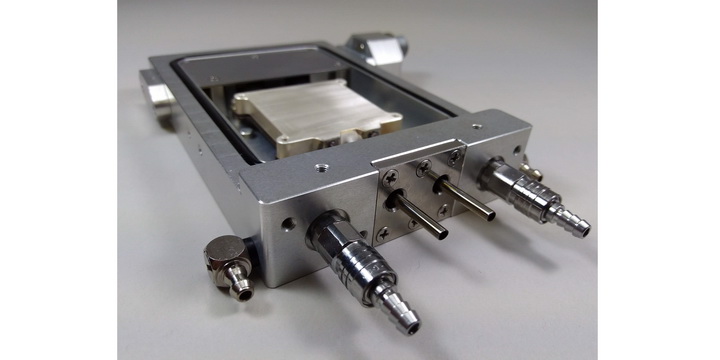

Square Hot and Cold Plates without Cover |

|

Benchtop workhorses for all purpose laboratory use |

Benchtop workhorses for all-purpose laboratory thermal control |

Benchtop workhorses for thermal control in any application |

|

Precision temperature control from -30°C ~ 120°C (Cooling down to -30°C without using LN2) |

Precision temperature control -190°C ~ 600°C depending on model |

-190°C ~ 600°C depending on model |

|

Standard square plates from 40 mm to 300 mm |

Standard square plates from 50 mm to 300 mm |

Standard square plates from 50 mm to 300 mm |

|

Optional frames with sealed covers for gas purging or vacuum capability |

Frames with sealed covers for gas purging ( vacuum optional ) |

Frameless design integrates in narrow spaces |

|

Removable handles and electrical feedthrough options |

Removable handles and electrical feedthrough options |

|

|

Bench mounting capability |

|

COMPACT THERMAL PLATES

HP1200G |

HP1500G |

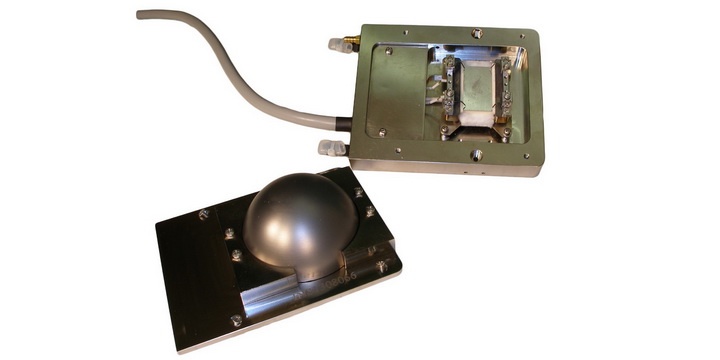

TP102SG |

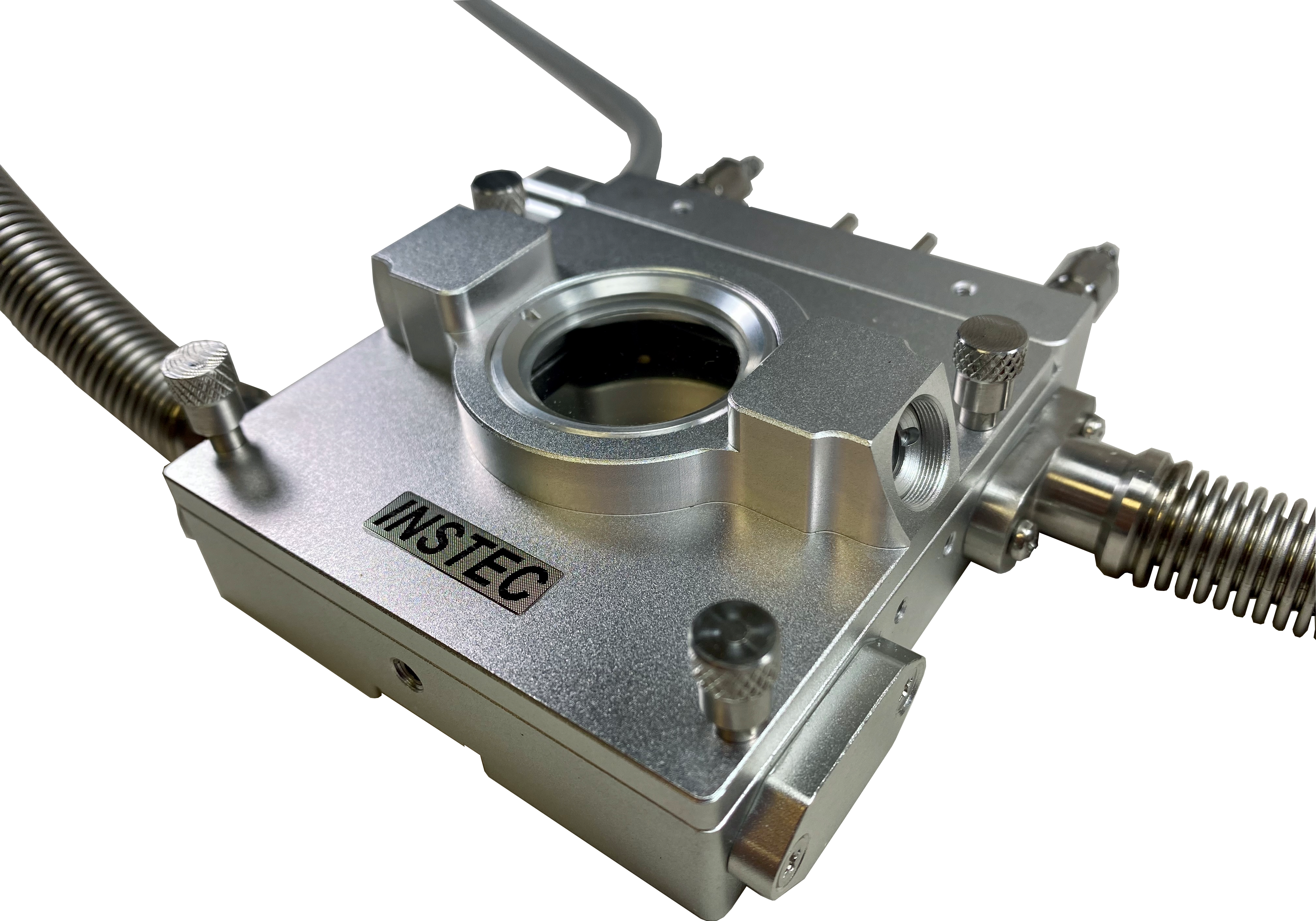

HCP621G |

HCP421V |

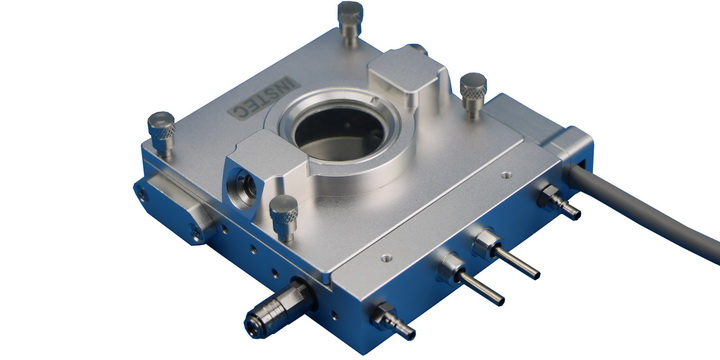

HCP622G |

|

High temperature microscopy & spectroscopy plate |

High temperature microscopy & spectroscopy stage |

Thermoelectric cooling stage enables cooling without use of liquid nitrogen |

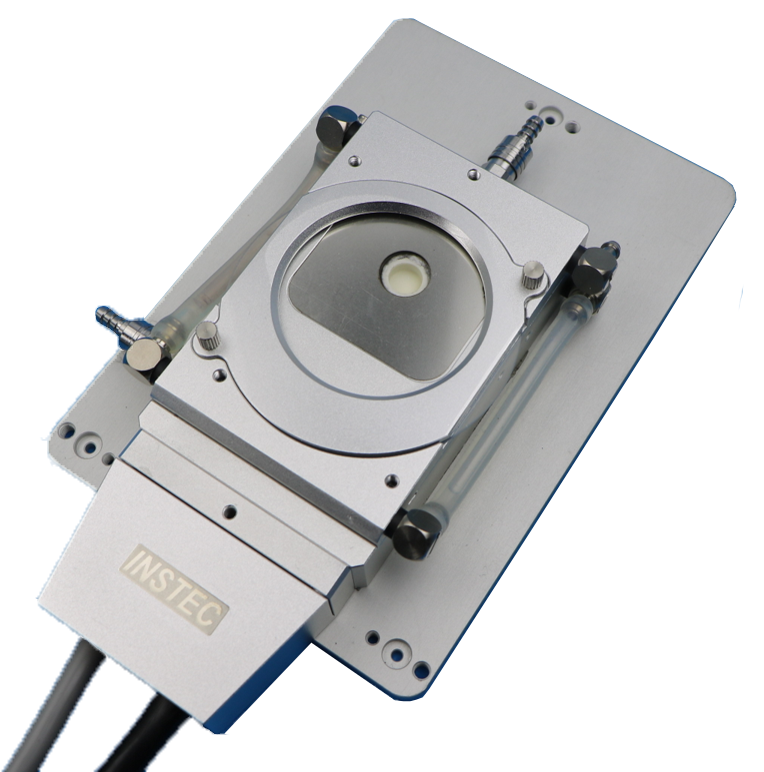

Best-selling do-it-all tool for microscopy and spectroscopy in a compact design that integrates with all instruments |

Compact reflection stage for microscopy & spectroscopy |

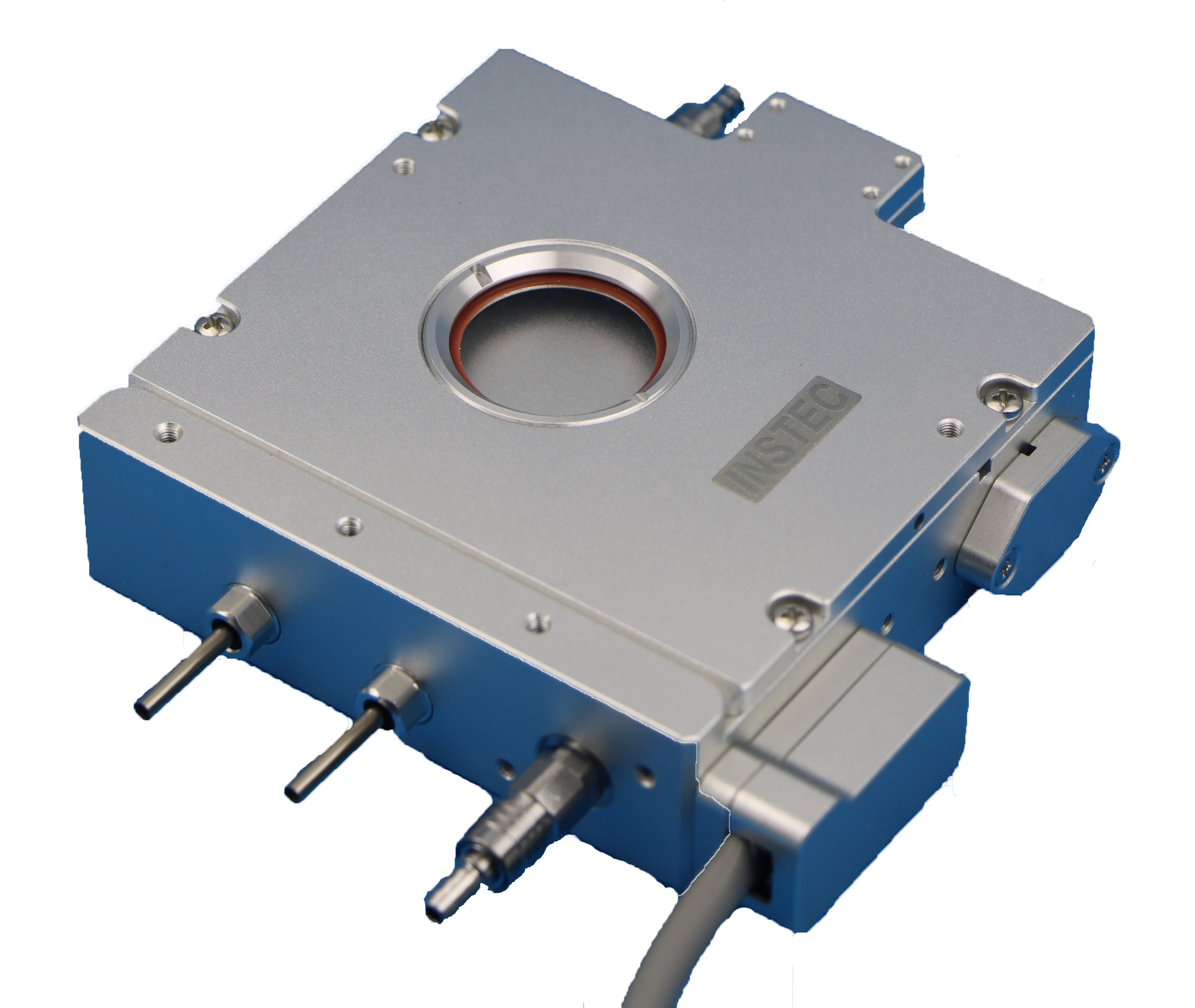

Compact microscopy and spectroscopy stage |

|

30°C ~1200°C |

30°C ~ 1500°C |

-40°C ~ 120°C |

-190°C ~ 600°C with liquid nitrogen cooling option |

-190°C ~ 400°C with liquid nitrogen cooling option |

-190°C ~ 600°C with liquid nitrogen cooling option |

|

Φ12 mm sample area |

8 mm diameter sample area |

40 mm x 40 mm |

28 mm × 30 mm sample area |

28 mm × 30 mm sample area |

35mm × 35mm sample area |

|

Gas-tight chamber *Vacuum-tight model available (HP1200V) |

Rotating sample observation window |

Gas-tight chamber *Vacuum-tight model available (TP102SV) |

Sealed chamber with gas purging capability |

Sealed vacuum-tight chamber |

Sealed gas-tight chamber |

SPECIALTY THERMAL PLATES

|

|

|

|

|

|

HCP421V-ELP |

HCP621G-ELP |

HCP600G-CAP |

HP1100XR - 1100°C |

TP102LC4 |

|

Compact plate for Ellipsometry applications |

Compact plate for Ellipsometry applications |

Compact Hot/Cold Plate for capillary tube applications |

HOT PLATE FOR X-RAY REFLECTION |

Temperature-controlled Automatic Liquid Crystal Testing (ALCT) measurements. |

|

70° incident & emergent light angles |

70° incident & emergent light angles |

Manipulate capillary tube while maintaining chamber atmosphere |

φ360° azimuth angle |

For use with Instec’s S-type and SG-type LC cells |

|

-190°C to 400°C with liquid nitrogen cooling option |

-190°C to 600°C with liquid nitrogen cooling option |

-190°C ~ 600°C |

1100°C high temperature |

-30°C ~ 90°C |

|

28 mm × 30 mm sample area |

28 mm × 30 mm sample area |

28 mm × 30 mm sample area |

Sample size 15 x 15mm |

|

|

Vacuum-tight chamber |

Gas-tight chamber |

Gas-tight chamber |

Graphite dome cover |

FEATURES

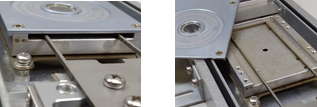

THERMAL BLOCK

- The heart of all electrical probe systems, stages, chucks, and thermal plates is a thermal block or sample plate for heating and cooling

- Built from aluminum, silver, or ceramic depending on the intended temperature range

- Embedded with heating elements and liquid nitrogen cooling channels as well as temperature sensors to provide the most precise thermal control for the sample

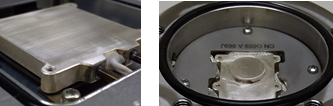

SAMPLING AREA

- The sample area of the heating block is the effective area over which the set temperature is maintained

- Typically flat to heat and cool samples from the bottom, but can be designed to accommodate samples of different dimensions

- Sample surfaces can be made with/without a transmission aperture

- Chuck surfaces can be made with vacuum grooves for securely fixing samples

- Place samples directly on the surface, on or in the arm of the XY positioning mechanism, or in custom-built holders

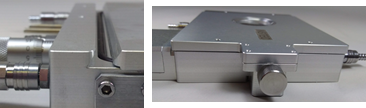

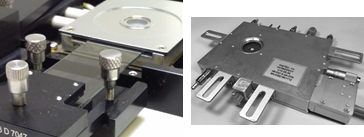

SAMPLE POSITIONING

- Position samples anywhere within the sampling area for fast in situ adjustments

- Precisely align specific sample features in optical paths

- Consists of a thin metal square or circular looped arm that extends over part of the sample area

- Arm is controlled externally by Vernier dials with 10mm of travel in two dimensions

- Greater flexibility, sample area accessibility, and precision control in moving the sample inside the chamber than in moving the stage on the microscope

- XY positioning is optimal for use with a rotational stage on a polarizing microscope due to the directional nature of polarization

FRAME & OUTER COVER

- Solid lightweight aluminum construction for some models

- Cover edge slides easily under beveled lip in the frame and cover is held securely in place with spring-loaded screws, for some models

CHAMBER HEIGHT & INNER COVER

- The chamber height is the distance between the top surface of the thermal block and the bottom surface of the outer cover, when inner cover is present

- This distance is minimized in design to allow for just enough height for intended samples (slides, slipcovers, wafer pieces, and any clamps or probes) and to decrease the minimum objective working distance

- Some stages feature a removable inner cover with a separate built-in window

- The inner cover significantly reduces vertical temperature gradients

SAMPLE LOADING

- Some models feature convenient sample side loading and unloading without opening stage covers

- Some models feature covers configurable to swing or pivot from any single corner for quick sample access

MOUNTING

- Various mounting adaptors are available for all most all microscope models, or other instruments

- Vertical mounting is possible for almost all Instec stages, for horizontal beam access to the samples

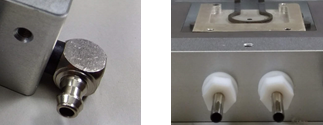

GAS PURGING & VACUUM PORTS

- Some models feature gas purging capability

- Either port can be input or output for purging gas flow

- Some models feature vacuum capability

- Two ports allow one to be used for pumping and the other for a pressure gauge

FRAME COOLING

- For some models, the integrated frame cooling dissipates heat and allows the frame to remain cool or warm to the touch

LIQUID NITROGEN COOLING

- Integrated liquid nitrogen cooling on some models allows precision thermal control down to -190C

- Different LN2 pump options are available

- Different Dewar sizes are available

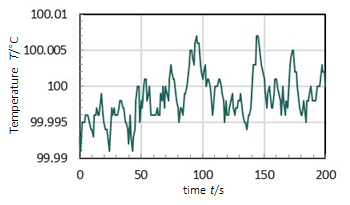

THERMAL CONTROL, mk2000 Temperature Controller

STATIC OPERATION

- In normal operation the controller uses a PID algorithm to adjust heating power and cooling pumping flow to maintain the current temperature

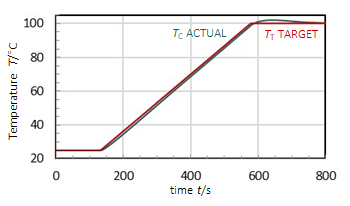

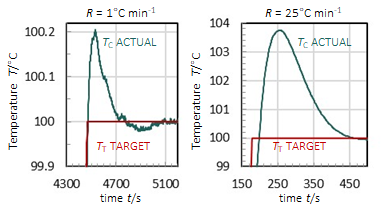

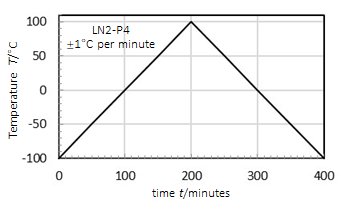

RAMP OPERATION

- To ramp to a user-defined target temperature TT at a specified ramp rate R from a current temperature TC, the controller calculates a target temperature profile

- The controller then adjusts the heating power and cooling pumping flow to achieve the target temperature profile

- In a real system, the wiring, a sample on the heating block, and the surrounding atmosphere are thermal loads that dissipate power

- Electrical and thermal inertia can result in short time delays in electrical and thermal responses and in achieving stability in the target temperature

- Faster ramp rates can result in greater overshooting of target temperatures because of thermal inertia

- Overshoot and delay can never be eliminated fully in a real system, but can be minimized by using the slowest ramp rate possible for the process

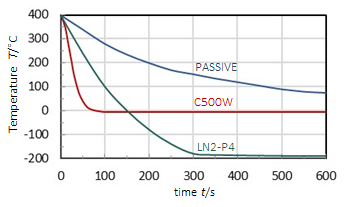

SAMPLE COOLING

- To achieve below ambient temperatures an active cooling system is necessary: a recirculating water chiller or a liquid nitrogen cooling system

- Active cooling has the advantage over passive cooling to allow fast experiment cycling

FRAME COOLING SYSTEMS

- Frame cooling option with recirculating chiller allows thermal control of frame independent of sample thermal block

- Keeps frame safe to touch and prevents frost buildup on windows

LIQUID NITROGEN COOLING SYSTEMS

- Liquid nitrogen systems provide sample cooling to as low as -190°C depending on pump power and thermal block size

- Systems consist of a pump, a Dewar, a lid with a stoppered port for refilling during operation, and connecting tubing

- Three liquid nitrogen pump output options available, LN2-P2, LN2-P4, and LN2-P8, which suction liquid nitrogen through the equipment and are controlled by the mK2000

- Three Dewar sizes, 2 L, 10 L, and 30 L, with easy refillable lid options to control liquid nitrogen supply to instruments

- Integrates with mK2000 PID controller with ±0.1% resolution

LIQUID NITROGEN SYSTEM MINIMUM TEMPERATURES |

|||

|

LN2-P2

|

LN2-P4

|

LN2-P8

|

|

|

CHUCKS & PLATES

|

|||

|

-40°C |

-60°C |

-120°C |

|

-20°C |

-40°C |

-100°C |

|

NA |

-30°C |

-80°C |

|

NA |

-20°C |

-60°C |

|

-120°C |

-170°C |

-190°C |