SWISS CLUSTER AG (Thun, Switzerland)

Swiss Cluster started in 2019 as a spin-off by a team of researchers and engineers from the Swiss Federal Institute for Material Science & Technology (Empa) in Thun, Switzerland. The company was officially registered on November 2020, and in May 2021 was granted the Empa spin-off label.

The expertise of the team covers various thin films deposition techniques (ALD, CVD, and PVD); vacuum and plasma deposition technologies; as well as in the whole realm of materials characterization. The combined knowledge in these fields are harnessed to bring novel ideas towards optimizing research and production processes to ultimately synthesize novel and better materials.

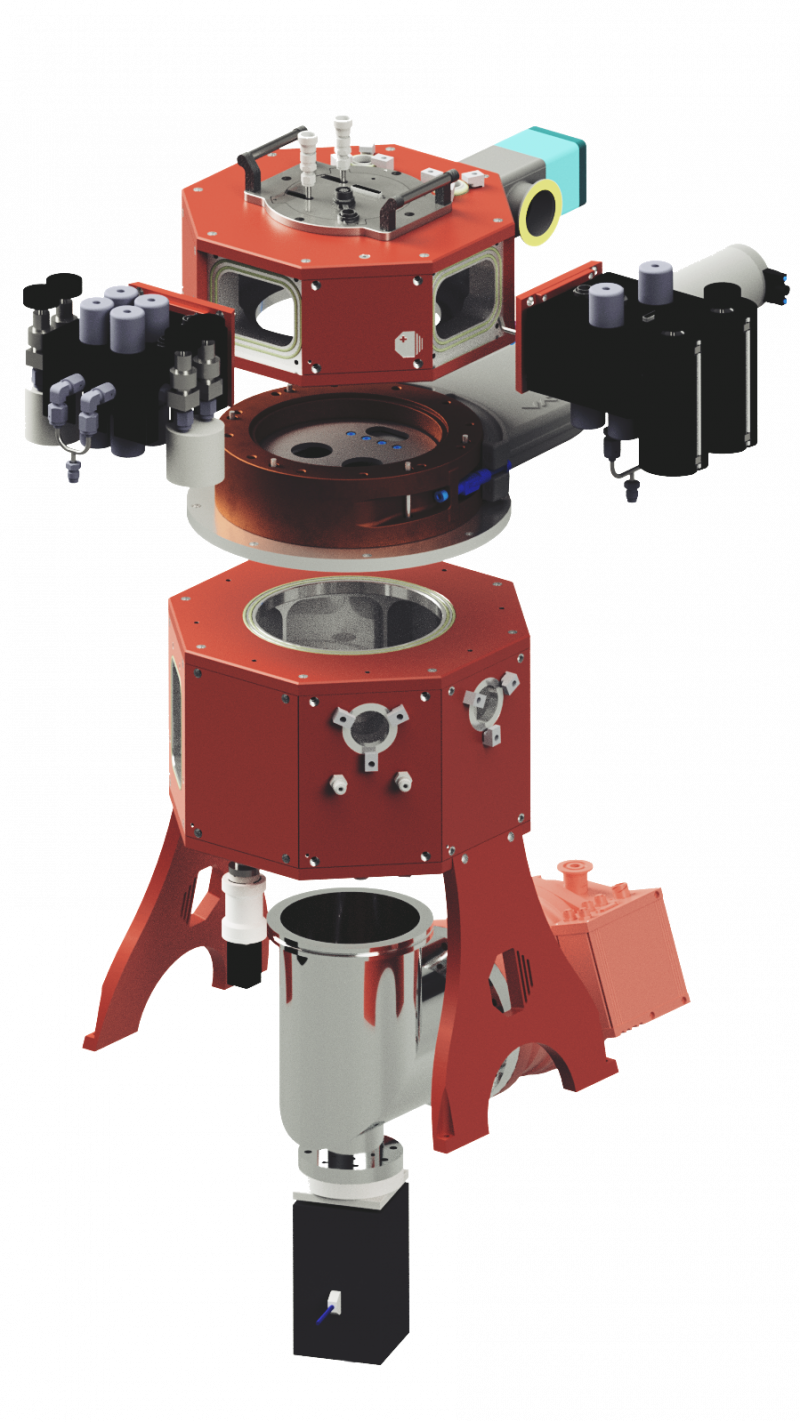

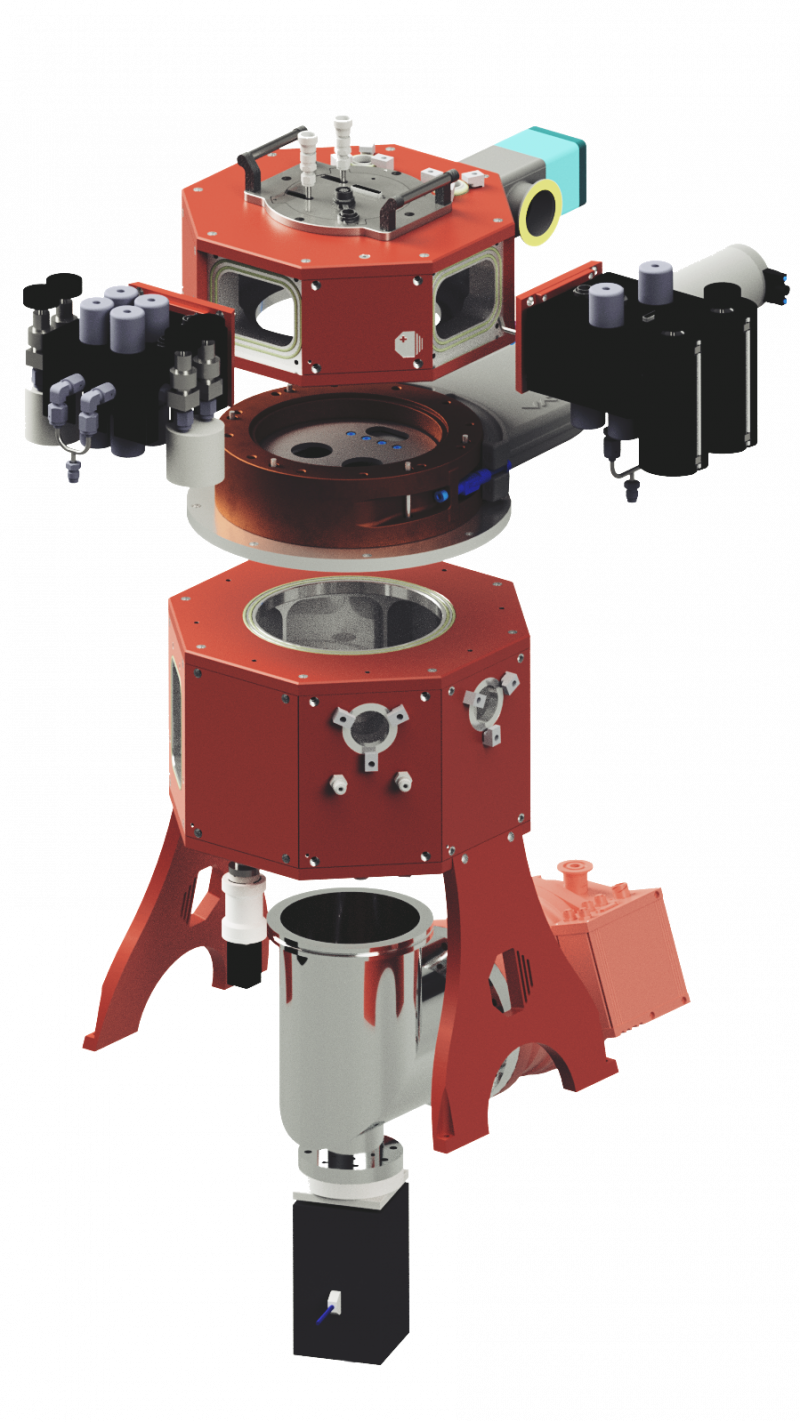

THE SC-1

The first compact cluster system for R&D

The SC-1 is our flagship deposition system that enables to research and develop the materials of the future. It features an innovative patent-pending cluster-design to create a compact, modular and fully automated multi-deposition equipment:

- Capable of performing both Atomic Layer Deposition (ALD) and Physical Vapor Deposition (PVD) without breaking the vacuum to fabricate films with hundreds of multinanolayers.

- No need for mechanical arms or antechambers; which significantly slow down the process, increase the complexity, lab space required and the investment costs.

- Modular and flexible system that allows to easily adapt new hardware and incorporate to our software.

THE SC-1 Combined ALD+PVD

FEATURES

MATERIALS FACTORY

With the benefits of both ALD and PVD

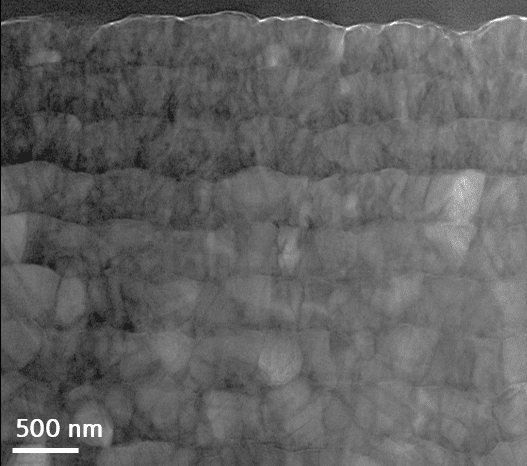

Multinanolayered Materials

Hundreds of multinanolayers of multiple material systems from the PVD and ALD materials library can be fabricated. The combination of ALD and PVD layers creates unique microstructures and properties to fit in your desired application.

Combinatorial Approach

The ALD-PVD microstructure can be further tailored with different film thicknesses along the cross-section and with different deposition temperatures throughout your substrate and process using our temperature gradient stage (TGS).

MODULAR

Customizable and Upgradable

Expandable

The ALD and PVD chambers in the SC-1 can be acquired and operated individually and then be upgraded to a cluster system. New hardware components or in-situ metrology equipment can be added and incorporated to our software and recipe creator.

Compact

By reducing the need of antechambers and mechanical arms, we reduce the complexity and lab space required.

FAST

Accelerating R & D

Automated

The system is fully automated; all the devices and components are connected to our easy-to use software. Hundreds of multinanolayers with both ALD and PVD can be fabricated with the push of a button.

Smart R&D

The temperature gradient stage (TGS) allows to screen a large temperature window to scan precursors, growth rates, microstuructures, chemical compositions, mechanical behaviour and more in a single deposition.

User-Friendly

Plug-and-Play functionality for beginner and advanced users.

Recipe Creator

With our easy-to use recipe creator, complex recipes can be made easy in order to fabricate hundreds of multinanolayers with different parameters in both ALD and PVD process during the deposition.

Low-Maintenance

The easy attachable/detachable panels makes this equipment extremely easy to replace, clean and service the parts.

The combination of ALD and PVD layers creates a unique microstructure with improved mechanical and thermal properties.

SPECIFICATIONS

HARDWARE

Substrate Sizes

- 4 inch wafers

- 6 inch wafers

- Different substrate holders available

Temperatures

- Up to 400 °C

- A gradient of 30 °C to 500 °C using our Temperature Gradient Stage

ALD Precursor Lines

- Up to 12 precursors with individual inlets - bottles and bubblers

Magnetrons

- Up to 4 magnetrons with 3 in. targets

Dimensions

- L x W x H (1250 mm x 600 mm x 1210 mm)

Add-ons

- Microwave plasma sources (PE-ALD)

- In-situ wafer stress measurements

- Customized ports and flanges

ALD-PVD Materials

- Al2O3, TiO2, ZnO, Y2O3, ZrO2, HfO2, Cu, Al, Ti, and more...

ELECTRONICS & SOFTWARE

Mass Flow Controllers

- 4 Analog MFC

- 60 Digital MFC

Pneumatic (ALD) valves

- 24 valves

Pressure Sensors

- 4 Analog

Gate valves

- 3 gate valves with feedback

Flow meters

- 4 Flow meters

Temperature

- 16 Channel PID regulation with K-Type sensors

- 4 PT100/PT1000

Interlocks

- 8 Interlock in

- 12 Interlock out

Additional Connections

- 2 Ethernet

- 2 RS485

CUSTOM SOLUTIONS

To meet your precise demands

EXPERTS IN ALD & PVD

We take your materials challenge and take it to production, from proof of concept to the design and development of your industrial coating system for manufacturing.

We provide technical, scientific, end engineering services for:

- R&D of new coating materials - Proof of concept

- Implementation of a new material into industrial production - Process development

- Electronics and software control systems for existing equipment

- Design and development of customized coating systems with our innovative concepts that challenges a 40 year industry standard

ANALYSIS

- Analysis of your demands and requirements

- Proof-of-concept coatings

- CFD and temperature simulations for homogeneously coating your particular 2D and 3D objects

- Definition of the concept

DESIGN

Design of hardware and software with our concepts aimed to:

- Reduce overall process times : Loading, Heat up, coating process, cool down, etc.

- A homogeneous coating process

- A user-friendly experience

- A clear line of communication to address your goals

PRODUCTION

- Fabrication and assembly

- Testing of the system

- Process development and optimization of times

- Materials characterization

INSTALLATION

- Delivery of system

- Training on site

- Assistance and follow-up on your progress

R&D services

To realize your material goals

- Design of new materials for specific applications

- Proof-of-concept coating materials

- Test and screen new gas precursors

- Scan a temperature range to identify deposition parameters

- Combinatorial deposition techniques for material discovery

- Fine-tune microstructure, morphology, stoichiometry, etc.

- Materials characterization

- Process development

- Translate R & D materials into production

The SC-1 The first compact cluster system for R&D

THE SC-1

The SC-1 is an innovative patent-pending cluster system:

- Atomic Layer Deposition (ALD) and Physical Vapor Deposition (PVD)

- No need for mechanical arms or antechambers

- Modular, flexible and customizable system