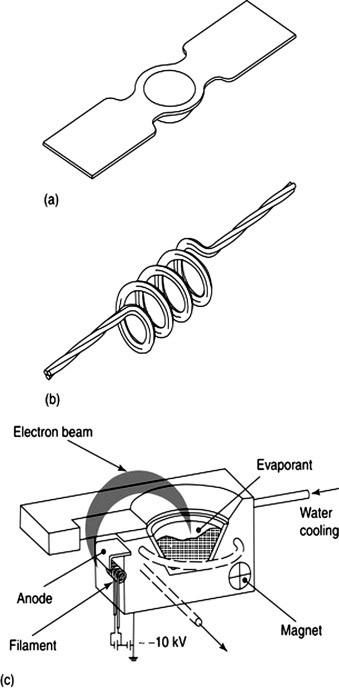

The evaporation process is a common technology for PVD coating, and it comprises evaporating source materials in a vacuum chamber below 1 × 10−6 torr (1.3 × 10−4 Pa) and condensing the evaporated particles on a substrate. Usually, the heating element which was used for evaporating source materials is often referred to as an "evaporation crucible".

Evaporation sources are generally made of refractory metals (with very high melting points) such as Cu, W, Mo, or Ta, with or without ceramic coatings, or refractory ceramic materials such as quartz, Al2O3, ZrO2, BN, BN-TiB2 and graphite.

Alumina (Al2O3) Crucible

- High thermal conductivity

- Excellent thermal shock resistance

- Low thermal expansion

- Exceptional heat resistance

- Good Chemical Inertness

- High electrical resistance

- Low dielectric constant and loss tangent

- High volume resistivity

- Excellent machinability

Tantalum (Ta) Crucible

- High melting point up to 2996°C

- Highly resistant to corrosion

- Moderate hardness and ductility

- Excellent chemical properties

- Does not react to hydrochloric acid, concentrated nitric acid and aqua regia under hot and cold conditions

- It can be used to manufacture evaporation vessels and can also be used as electrodes, rectifiers and electrolytic capacitors for electronic tubes

Molybdenum (Mo) Crucible

- High density over 10g/cm3

- It has great strength under high temperature, anti-friction corrosion resistance

- High thermal conductivity

- High thermal expansion coefficient

- Ra<6.3

- Mainly used as containers and heating element for evaporation coating machine in optical glasses and spectacles field

- Excellent machinability

Tungsten (W) Crucible

- High density over 18.7g/cm3

- Excellent corrosion resistance

- High melting and boiling points

- High temperature strength

- High abrasion resistance

- Ra<6.3

- The crucible can be used in vacuum inert gas environment under the temperature of 3400℃

- Excellent machinability

Copper (Cu) Crucible

- High density

- Excellent corrosion resistance

- Low resistivity

- High Strength

- Ra<6.3

- Using temperature below 1083.4ºC in vacuum or deoxidize atmosphere

- Excellent machinability

Niobium (Nb) Crucible

- High density

- Excellent corrosion resistance

- Low resistivity

- High Strength

- Ra<6.3

- Using temperature below 2450ºC in vacuum or deoxidize atmosphere

- Excellent machinability

Boron Nitride (BN) Crucible

- High thermal conductivity

- Excellent thermal shock resistance

- Low thermal expansion

- Exceptional heat resistance

- Good Chemical Inertness

- High electrical resistance

- Low dielectric constant and loss tangent

- High volume resistivity

- Excellent machinability

All other evaporation crucible available on request.

Customization available.

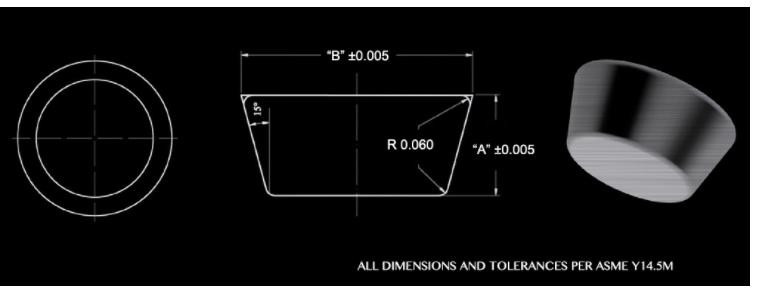

The most common evaporation sources we make are the following 3 types.

Wire type evaporation sources

It’s made from tungsten wire and can be formed into filaments, baskets, heaters or looped shaped point sources.

Boat type evaporation sources

It’s made from tungsten, tantalum, molybdenum or ceramic type materials capable of withstanding high temperatures.

Crucible liners type evaporation sources

It’s made from tungsten, tantalum, molybdenum, copper, graphite and refractory ceramic materials.

검색 결과 4건

- 분류 : 박막증착타겟

Why You Choose Us

We Can Not Only Provide You With Excellent Service, Cost-Effective and Good-Quality Products, But Also Customize Products According To Your Needs

Stable Supply Chain

With a well-established stable supply chain and long-term partnership with suppliers, we better respond to your needs with no delay and secure the materials supply for you.

Strict Quality Control

Trusted by the world's leading enterprises, famous universities and institutes, the supplier follows the quality standard ISO 9001 and ISO 14001 in the whole process of PVD coating products.

Fast Lead Time

We can follow your schedule and remain quality as a excellent supplier even if you need it urgently. Regular products are in stock, and customized products are delivered within 2-4 weeks; Enjoy fast production with experienced manufacturers directly.

Full Customer-orientation

We have worked for 20+ years with most of our customers for the sales of scientific equipments, as customer value and satisfaction are always our first thoughts.

One Stop Solution

We can provide a full range of solutions for materials science and the analytical solutions.

하기