A300-XP UHV Magnetron Sputtering Sources

The AJA A300-XP UHV Magnetron Sputtering Sources are the next generation, "expanded performance" version of the industry standard A300 SERIES magnetron sputtering sources that have dominated the high end, UHV sputter gun market since 1991. New "expanded performance" features include higher pressure operation, improved magnetic material sputtering performance, and a larger product range. Although our competitors have attempted to incorporate certain "AJA innovations" into their product lines during the last 10 years, the new A300-XP source developments will continue to ensure AJA's position well ahead of the pack in the UHV magnetron market.

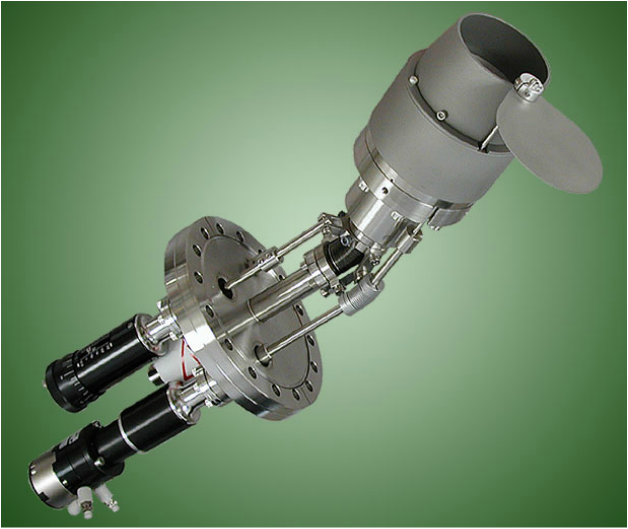

Shown above is a typical A320-XP 2" UHV source with in-situ tilt, pneumatic shutter, gas ring, conical chimney and integral gas injection.

4" Target UHV magnetron sputtering source on 8" CF rotatable flange

(bolt ring not shown) with chimney, gas ring and pneumatic shutter.

UHV magnetron sputter source with in-situ tilt shown in a con-focal orientation

for uniform deposition onto 150 mm Ø substrates.

A310 Series Miniature UHV Magnetron Sputtering Sources

AJA’s unique A310-XP source fits through the port of a 2.75” CF flange. Target changes can be made with one hand either inside or outside of the chamber. This revolutionary design is full ceramic to metal construction. These sources can also be combined into multi-gun clusters.

The design is ideal for Surface Science chambers and anyone working with small substrates (up to 2” Ø). The A310-XP is suitable for RF and DC operation.

CTM Series Magnetron Sputtering Sources

In 1994 AJA was awarded a joint patent with the U.S. Air Force for the CTM (Conical Target Magnetron) designed to provide efficient off axis deposition of HiTC superconductors. Variations have since been created. Most current applications are based on minimizing damage due to high energy ions or neutrals. One particularly interesting application is the deposition of conductive oxides such as ITO for displays. These sources all feature integral process gas distribution and are available in both HV and UHV versions.

Unique Modular Magnet Array

AJA's magnetron sputtering sources feature a unique "modular magnet array" which is completely isolated from the cooling water to eliminate magnet deterioration and subsequent degradation of source performance. This design permits access to the internal magnet arrangement thus allowing the same source to be:

- Operated as a balanced magnetron

- Configured for maximum target utilization

- Configured for high or low rate sputtering

- Operated in a variety of unbalanced magnetron configurations

- Changed for uniform or intentionally non-uniform depositions

- Configured for high or low electron energies as they arrive at the substrate surface

- Operated with thick magnetic material targets

- Optimized for easy magnetic target removal and replacement

Typical Features

- Modular magnet array isolated from cooling water

- Magnetic material sputtering of thicker targets

- Easy removal of larger magnetic targets

- Integral gas injection and chimney system

- Efficient target cooling with no vacuum/water seals

- Clamped target mounting for optimal heat transfer

- RF & DC compatibility

- Rugged HV construction

- Operating pressure: (0.3 mTorr - 1.0 Torr)

- In-situ tilt or manual tilt for optimum uniformity

- Custom versions available

- Source/power supply/target packages available

Typical Applications

- CD/DVD disk coatings (e.g. reflective, phase change)

- Semiconductor

- Conductive metal/resistive metal/Insulating Films

- Transparent electrical conductors (e.g. ITO)

- Optical communications applications (e.g. pump lasers)

- Wear resistant films

- Lens coatings (reflective/anti-reflective/ hard/color)

- Precious metals (for maximum target utilization)

- Thin film sensors

- Coatings for surgical/medical implements & implants

- Magnetic storage media and heads (HD, GMR , TMR)

- Photovoltaic thin films (solar cells)