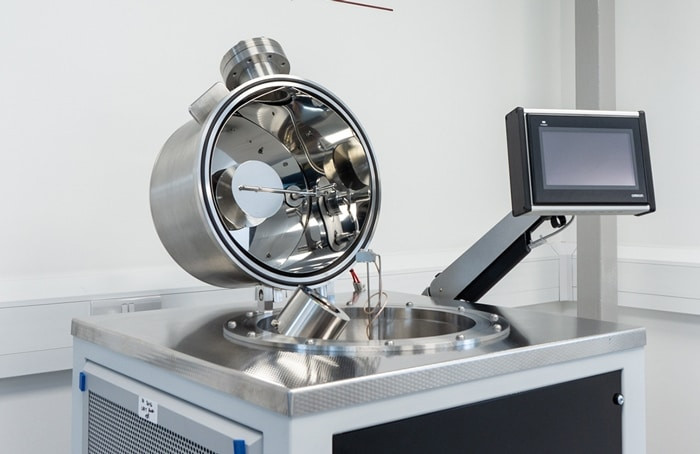

MiniLab 026 시스템은 evaporation 및 sputtering 기술을 이용한 금속, 유전체 및 유기물 증착에 적합합니다. ‘Clam-shell’ chamber를 갖는 컴팩트한 floor standing vacuum evaporator입니다.

Techniques:

Thermal evaporation, Low-temperature thermal evaporation (LTE), Magnetron sputtering

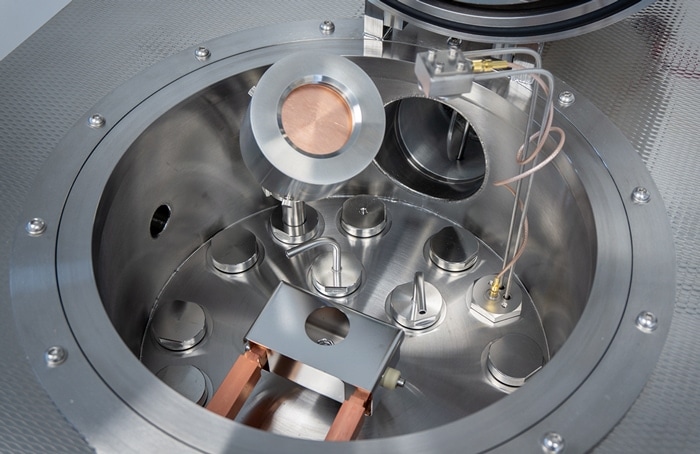

MiniLab 026 진공증착시스템에는 터보펌프가 포함되며, 본 펌프는 진공챔버의 후면 ISO100 포트에 놓입니다. 진공 챔버의 베이스도 서포트 프레임에 안착됩니다. Chamber lid는 Edwards E306과 유사한 스테인리스 스틸 top-hat style lid (즉, 'clam-shell' 유형 챔버) 또는 bell-jar 일 수 있습니다. MiniLab 026 시스템에는 다양한 증착 기술이 장착됩니다.

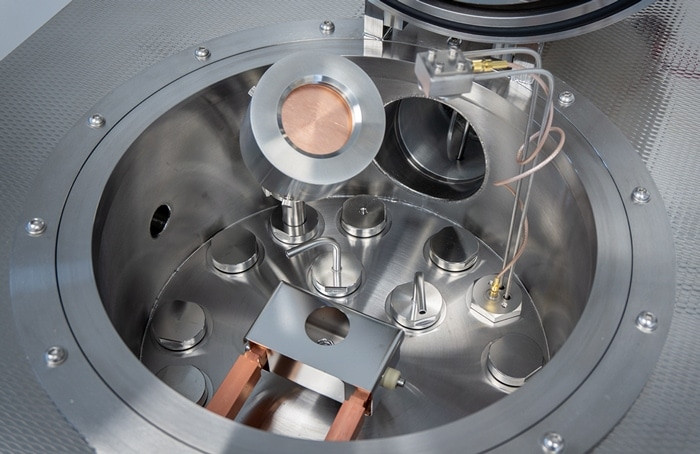

MiniLab 026의 기술은 열증착 및 저온 증발 소스(금속 및 유기물) 및 마그네트론 스퍼터링 소스(금속 및 무기물)에 적용됩니다. 증착 소스는 일반적으로 chamber baseplate에 장착됩니다. 기판 스테이지는 루프에 지지되며, 최대 6" 직경의 다양한 기판을 수용할 수 있습니다. 기판 가열, 회전 및 Z-shift를 사용할 수 있습니다. MiniLab 026은 또한 글로브박스와 호환되며 기존 글로브박스에 쉽게 적용될 수 있는 MiniLab 제품군의 유일한 시스템입니다.

Key features

- Modular design

- ‘Clam-shell’ or bell-jar chambers

- Turbomolecular pumping systems

- Base pressures <5 × 10-7 mbar

- Up to 6” diameter substrates

- Touchscreen HMI/PC for system control

- Equipped for easy servicing

- Comprehensive safety features and interlocks

- Cleanroom compatible

- Proven performance

- Glovebox-compatible

Options

- Pumping: Rotary or scroll backing pumps.

- Gas/pressure: Manual or automatic control via MFCs and throttle valves.

- Stages: Rotation, heating, and Z-shift.

- Shutters: Source and substrate, pneumatic or motorised.

- Operation: Manual or automatic via front panels, touchscreen HMI or PC.

- Process: Quartz crystal sensor heads for rate/thickness monitoring or feedback-loop control.

Typical configurations

Thermal evaporation (metals):

Three-source TE3 thermal evaporation component with source shutter and rotation stage. High power TEC-4A power supply and controller with recipe-based automated control. Quartz crystal sensor head with PC software for rate/thickness monitoring.

Thermal evaporation (metals and organics):

Two-source TE2 thermal evaporation component for metals and LTE-1CC component for organics. Source shutters and rotation stage. Evaporation power supplies linked to quartz crystal sensor head and Inficon SQC-310 process controller for automated process control per user-defined rates/thicknesses.

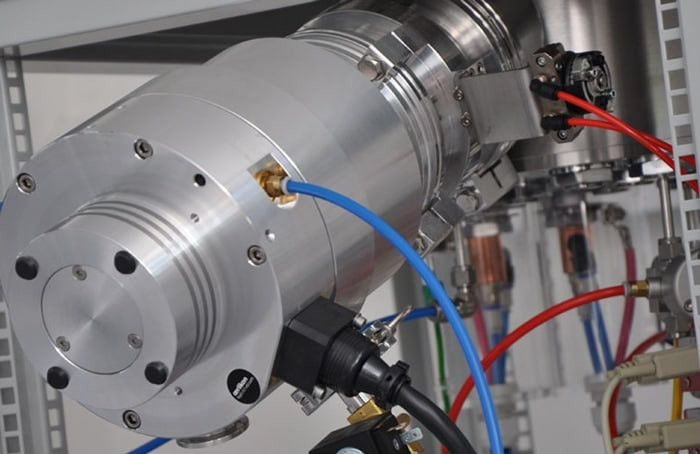

Magnetron sputtering:

Water-cooled magnetron source for 2″ diameter targets. RF power supply for metals and dielectrics. Source shutter and rotation stage. Recipe-based power vs. time process control.

MiniLab 026 systems are compact floor standing vacuum evaporators with easy-access ‘clam-shell’ chambers. Suitable for metal, dielectric and organics deposition via evaporation and sputtering techniques.

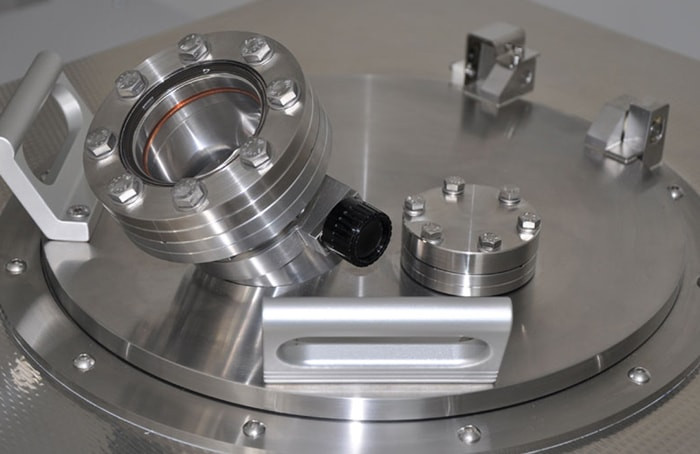

MiniLab 026 tools include a turbomolecular pump positioned on an ISO100 port at the rear of the vacuum chamber. The base of the vacuum chamber sits, as a well, into the supporting frame. The chamber lid can be either a stainless-steel top-hat style lid (i.e., for a ‘clam-shell’ type chamber arrangement), or a bell-jar — similar to the Edwards E306. Systems can be equipped with a wide variety of deposition techniques.

Techniques include thermal and low-temperature evaporation sources (for metals and organics), and magnetron sputtering sources (for metals and inorganics). Deposition sources are typically mounted on the chamber baseplate. Substrate stages are supported from the roof and can accommodate a range of substrate sizes up to 6” diameter. Substrate heating, rotation and Z-shift are available. The MiniLab 026 is also glovebox compatible and is the only system in the MiniLab range that can be easily retrofitted to an existing glovebox.

Service requirements

All MiniLab 026 tools require chilled water, dry compressed air, nitrogen for venting (optional) and electrical power. Sputtering systems also require process gases (argon, oxygen and nitrogen). Exact requirements will be provided with quotations or on request.