nanoCVD-WPG Wafer-scale CVD system은 고품질 그래핀을 빠르게 합성하는 강화 플라즈마 웨이퍼 급의 CVD(Chemical Vapour Deposition) 시스템입니다.

"A compact, plasma-enhanced, wafer-scale CVD (Chemical Vapour Deposition) system for rapid synthesis of high-quality graphene."

Techniques:

Applications include: Graphene & 2D materials, Electrodes for photovoltaics, Touchscreen displays, High-performance electronics Biological, chemical and mechanical sensors, Electrical energy storage

Developed in collaboration with academic partners, nanoCVD technology is proven for the rapid throughput production of high-quality graphene for R&D applications via the well-established chemical vapour deposition (CVD) route that is considered most promising for future commercialisation of graphene-based technologies.

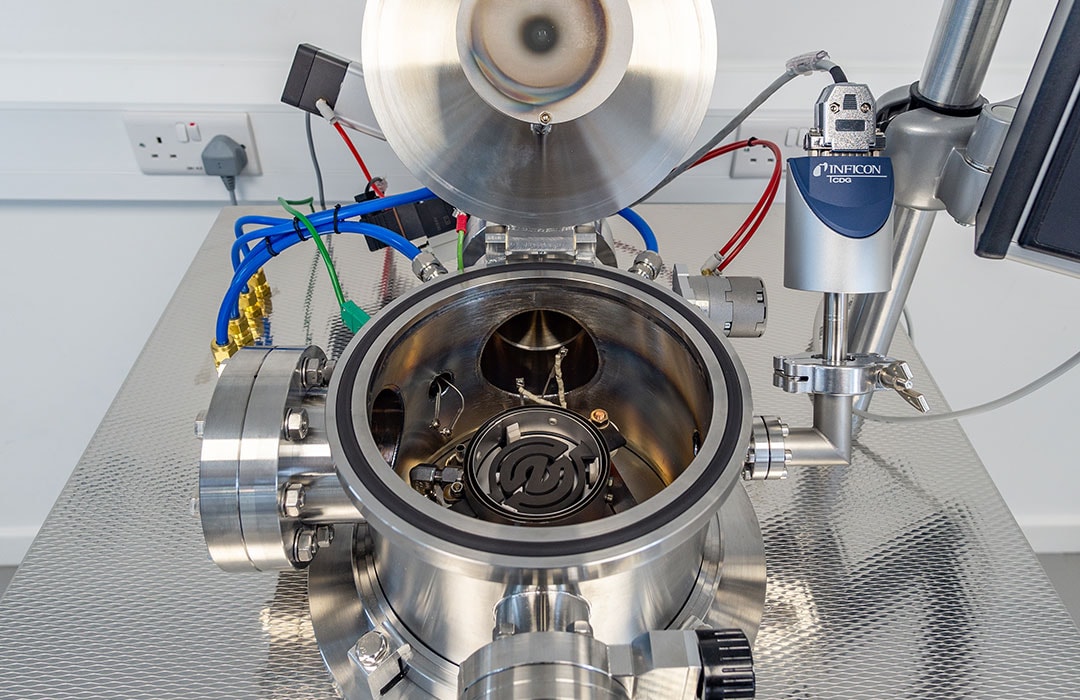

Model nanoCVD-WGP is the result of the scaling of this technology to the wafer scale (3” or 4”), together with the addition of plasma-enhanced capability in a cold-walled chamber. While this represents a significant leap in the capabilities of the nanoCVD range, intelligent design means the compact nature of the units has been maintained for efficient location and integration.

Growth schemes

Compatible with numerous CVD methods:

- Substrates: Cu, Ni, etc. (films or foils)

- Feedstocks: CH4, C2H4, solids (PMMA), etc.

- Process gases: H2, Ar, N2, etc.

Key features

- Compact design

- Wafer-scale synthesis: 3” or 4”

- 150 W/13.56 MHz RF power supply

- Multiple in-chamber plasma electrodes

- 1100 °C maximum platen temperature

- Cold-walled technology

- Fully-automatic control of critical conditions

- User-friendly, touchscreen interface

- Define/save multiple growth recipes

- PC connection for data-logging

- Equipped for easy servicing

- Comprehensive safety features

- Cleanroom compatible

- Implements proven nanoCVD technology

Typical configurations

- Process chamber: Cold-walled, stainless steel with heat shielding.

- Pumping system: Turbomolecular pumping system; <5×10-7 mbar base pressure.

- Substrate stage: Up to 4″ diameter. Up to 1100 °C with 1 °C control resolution.

- System operation: Touchscreen HMI and PC software. Manual or automatic control.

- Process gases: MFC controlled. Ar, CH4 and H2 as standard.

- Pressure control: Automatic.

- Plasma generation: 150 W/13.56 MHz RF power supply. Generation at substrate stage or remote electrodes.

- Safety features: Coolant and vacuum interlocks. Gas dilution modules.