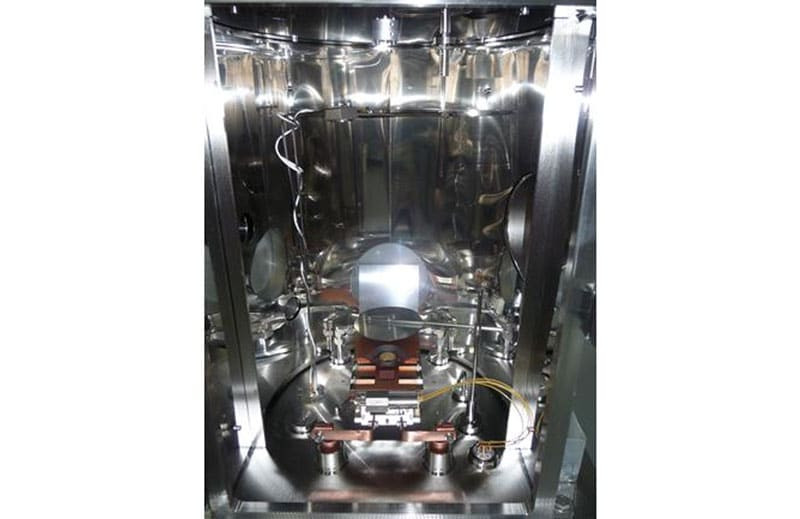

MiniLab 080은 최적의 균일한 증착 결과를 내고자 하는 열 증착 (thermal evaporation), e-beam evaporation, 저온 증착 (low-temperature evaporation)에 사용되며, MiniLab 080에는 working distance가 긴 챔버 (tall chamber)가 제공됩니다.

Techniques:

Thermal evaporation, Low-temperature thermal evaporation (LTE), E-beam evaporation, Magnetron sputtering

MiniLab 080은 최고의 균일성을 위해 긴 작동 거리를 필요로하고, 90°에 가까운 증발 입사각(evaporant incident angle)으로서 리프트 오프 애플리케이션(lift-off application)을 위한 최적의 결과를 도출하고자 하는 증착기술 요구사항에 매우 적합합니다. 또한 열 증착, LTE (저온열증착) 및 E-beam 증착 뿐 아니라 multi-technique에 의한 마그네트론 스퍼터링 장치를 장착할 수 있습니다.

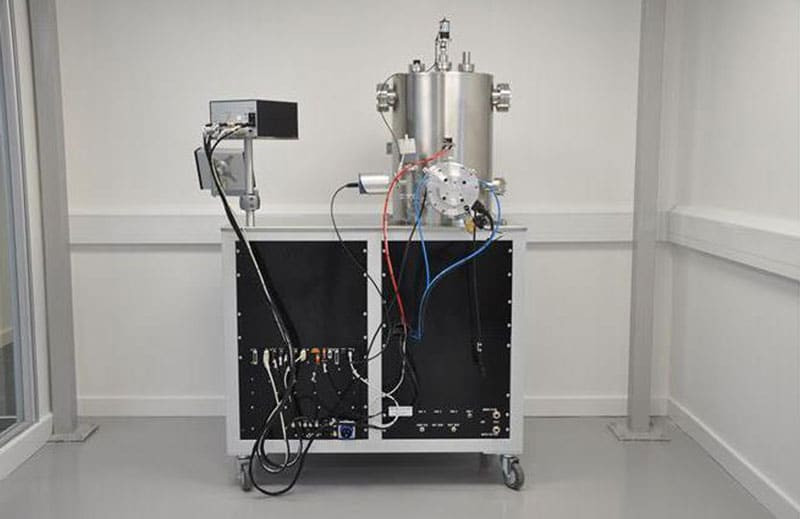

MiniLab 080 standard configuration에는 터보펌프가 포함되며, 이 펌프는 진공 챔버 후면의 ISO160 포트에 놓여있습니다. 진공 챔버는 모든 시스템 제어 전자 장치 및 전원 공급 장치를 포함하는 double-rack frame에 있습니다. MiniLab 080 시스템은 load-lock과 함께 사용할 수 있습니다.

일반적으로 챔버 상단에 있는 기판 스테이지는 최대 11" 직경의 기판 크기를 수용할 수 있습니다. 기판 가열 및 회전, bias 및 Z-shift, planetary stage, 소스 및 기판 셔터와 함께 사용할 수 있습니다. 본 시스템은 수동 열 증착 시스템에서 완전 자동화된 프로세스 컨트롤러를 갖는 멀티테크닉 장비에 이르기까지 다양하게 구성됩니다.

Key features

- Modular design

- Front-loading D-shaped vacuum chamber

- Turbomolecular and cryo pumping systems

- Base pressures <5 × 10-7 mbar

- Metals, dielectrics and organics deposition

- Up to 11” diameter substrates

- Touchscreen HMI/PC for system control

- Equipped for easy servicing

- Comprehensive safety features and interlocks

- Cleanroom compatible

- Load-locks available

Options

- Pumping: Turbomolecular or cryogenic high-vacuum pumps, rotary or scroll backing pumps.

- Gas/pressure: Manual or automatic control via MFCs and throttle valves.

- Load-locks: Single- and multiple-sample.

- Stages: Rotation, heating, cooling, Z-shift, bias and planetary.

- Shutters: Source and substrate, pneumatic or motorised.

- Operation: Manual or automatic via front panels, touchscreen HMI or PC.

- Process: Quartz crystal sensor heads for rate/thickness monitoring or feedback-loop control.

Typical configurations

Thermal evaporation (metals):

Four-source TE4 thermal evaporation component with source shutters and rotation stage. High power TEC-4A power supply and controller with recipe-based automated control. Quartz crystal sensor head with PC software for rate/thickness monitoring.

Thermal evaporation (metals and organics):

Two TE1 thermal evaporation sources for metals and four LTE-1CC components for organics. Source shutters and rotation stage. Evaporation power supplies linked to quartz crystal sensor head and Inficon SQC-310 process controller for automated process control per user-defined rates/thicknesses.

E-beam evaporation:

Multi-pocket (e.g., 6 × 7 cc or 8 × 4 cc) water-cooled e-beam source with 5 kW power supply/controller and automated pocket selection. Source and substrate shutters, and rotation. Quartz crystal sensor heads with Inficon SQC-310 process controller for automated process control per user-defined rates/thicknesses.

MiniLab 080 systems offer tall chambers ideally suited for thermal, LTE and e-beam evaporation techniques requiring longer working distances for optimum uniformity.

The MiniLab 080 standard configuration includes a turbomolecular pump positioned on an ISO160 port at the rear of the vacuum chamber. The vacuum chamber sits on a double-rack frame that contains all system control electronics and power supplies. MiniLab 080 systems are available with load-locks—please call for details.

The tools are ideally suited to evaporation techniques where long working distances are required for best uniformity, and where evaporant incident angles close to 90° allow for optimal results for lift-off applications. However, as well as thermal, LTE and e-beam evaporation, the tools can also be fitted for magnetron sputtering (commonly as a multi-technique system).

Substrate stages, usually at the top of the chamber, can accommodate substrate sizes up to 11” diameter. Substrate heating, rotation, bias and Z-shift are available, together with planetary stages and source and substrate shutters. Configurations range from a manually operated thermal evaporation system up to a multi-technique tool with fully-automated process control.

Service requirements

All MiniLab 080 tools require chilled water, dry compressed air, nitrogen for venting (optional) and electrical power (three-phase for e-beam evaporation). Sputtering systems also require process gases (argon, oxygen and nitrogen). Exact requirements will be provided with quotations or on request.