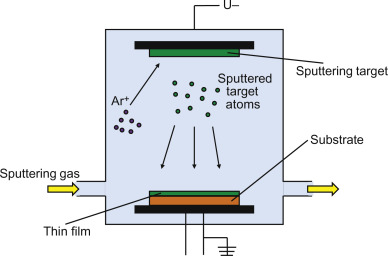

당사 (주)연진에스텍은 PVD 코팅 소재의 전문 공급업체로, 고객사의 용도에 따라 가장 적합한 고품질의 스퍼터링 타겟을 판매합니다. PVD는 금속, 세라믹, 플라스틱 등의 재료를 기판(샘플)에 증착하고 박막을 형성하는 증착 코팅 기술입니다. 일반적으로 스퍼터링과 증발의 두 그룹으로 나눌 수 있습니다. 스퍼터링 기법은 스퍼터링 타겟으로부터 원자를 방출하고 방출된 원자를 고진공 환경에서 기판에 타겟을 증착하는 물리 기상 증착(Physical Vapor Deposition, PVD) 공정입니다. 스퍼터링 타겟은 PVD 박막 코팅에 사용되는 필수 물질입니다. 스퍼터링 타겟은 PVD 시스템에 사용되는 금속 또는 합금, 세라믹과 같은 고체 물질입니다. 진공 상태에서 고에너지 플라즈마에 노출되면 타겟의 원자가 방출되어 기판 표면에 균일한 박막을 형성합니다. 이러한 막은 microelectronics, photovoltaics, 광학 및 보호 코팅에 필수적입니다.

구매 문의 Contact 02)2675-0566 ~7, info@yeonjin.com

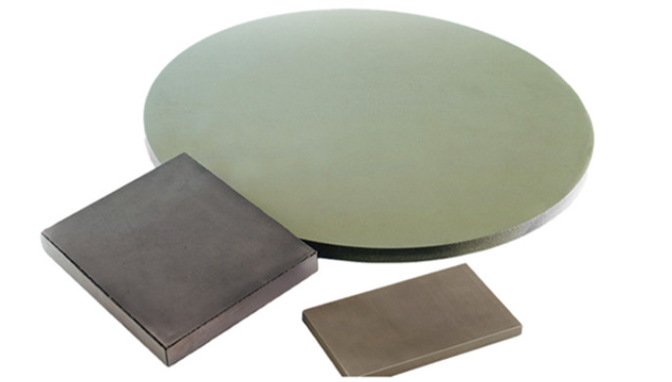

Different Shapes of Sputtering Targets

(주)연진에스텍은 대부분의 증착 공정에 부합하는 다양한 형태의 스퍼터링 타겟을 제공합니다:

- Planar (Flat) Targets: 대부분의 마그네트론 스퍼터링 시스템에서 사용됩니다.

- Rotary (Cylindrical) Targets: 대량 처리, 대면적 코팅에 적합합니다.

- Disc & Circular Targets: 소규모 영역이나 R&D 에 주로 사용됩니다.

- Ring Targets: 고급 마그네트론 스퍼터링 증착에 자주 사용됩니다.

- Custom Geometries: 비표준 챔버나 특이한 요청 시 타겟 크기의 커스터마이즈가 가능합니다.

Key Features

- High Purity & Performance: 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety: 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing: 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design: 반복 가능하고 균일한 박막 결과를 위해 엄격한 허용 오차로 제조되었습니다.

- Flexible Supply Chain: 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.

Sputtering Targets We Offer:

- Pure Metal

- Alloy

- Oxide Ceramic

- Nitride Ceramic

- Carbide Ceramic

- Fluoride Ceramic

- Silicide Ceramic

- Sulfide Ceramic

- Boride Ceramic

- Selenide Ceramic

- Telluride Ceramic

- Rare Earth Elements

스퍼터링 타겟은 타겟의 화학 조성에 따라 Metal sputtering target, Alloy sputtering target, Ceramic sputtering target 3가지 종류로 구분합니다:

1) Metal sputtering targets

(주)연진에스텍은 희토류 금속을 포함하여, 주기율표에 있는 대부분의 금속 재료를 공급할 수 있습니다. 일반적으로 제조사에서 사용하는 생산 기술은 진공 용해 (vacuum melting)및 열간 가압 소결(hot pressed sintering)입니다.

(주)연진에스텍은 희토류 금속을 포함하여, 주기율표에 있는 대부분의 금속 재료를 공급할 수 있습니다. 일반적으로 제조사에서 사용하는 생산 기술은 진공 용해 (vacuum melting)및 열간 가압 소결(hot pressed sintering)입니다.

제조사는 단조 및 압연, 어닐링 공정의 기술 사양을 제어함으로써 완성된 스퍼터링 타겟은 고밀도, 낮은 가스 함량, 균일한 내부 구조의 특성을 가지며, 실 사용자는 PVD 공정 중에 일정한 erosion 속도와 고순도, 균일한 박막을 얻을 수 있습니다.

전자, 광학, 에너지 등 다양한 분야에서 박막 증착에 적합한 다양한 금속 타겟을 확인해 보세요.

2) Alloy sputtering targets

고객의 요구 사항이 무엇이든 당사는 고객과 상담해드릴 수 있는 기술과 전문성을 보유하고 있습니다. 저희는 맞춤형 합금 및 고순도 금속에 대한 최고의 공급업체라는 자부심을 가지고 있습니다. 고객에게 항상 최고의 품질을 제공하는 것이 저희의 목표입니다. 박막의 독특한 특성과 기능을 부여하여 다양한 응용 분야에서 박막의 성능을 향상시키도록 합금 타겟을 제공합니다.

고객의 요구 사항이 무엇이든 당사는 고객과 상담해드릴 수 있는 기술과 전문성을 보유하고 있습니다. 저희는 맞춤형 합금 및 고순도 금속에 대한 최고의 공급업체라는 자부심을 가지고 있습니다. 고객에게 항상 최고의 품질을 제공하는 것이 저희의 목표입니다. 박막의 독특한 특성과 기능을 부여하여 다양한 응용 분야에서 박막의 성능을 향상시키도록 합금 타겟을 제공합니다.

3) Ceramic sputtering targets

당사 (주)연진에스텍은 세라믹 도가니의 공급 분야에서 풍부한 경험을 보유하고 있으며, 코팅 산업의 스퍼터링 타겟으로 사용되는 산화물 및 비산화물 세라믹뿐만 아니라 금속 및 합금도 공급합니다. 타겟 혼합물의 경도, 내화학성, 시각적 특성 등 고객의 요구사항에 맞춰 광범위하게 공급할 수 있습니다.

당사 (주)연진에스텍은 세라믹 도가니의 공급 분야에서 풍부한 경험을 보유하고 있으며, 코팅 산업의 스퍼터링 타겟으로 사용되는 산화물 및 비산화물 세라믹뿐만 아니라 금속 및 합금도 공급합니다. 타겟 혼합물의 경도, 내화학성, 시각적 특성 등 고객의 요구사항에 맞춰 광범위하게 공급할 수 있습니다.

또 다른 중요한 분야는 세라믹 소재와 금속의 혼합물, 즉 서멧(cermet)입니다. 제조사는 원자재 처리부터 세라믹 제조, 가공, 타겟 본딩까지 전체 가치 사슬을 자체적으로 보유하고 있습니다. 뛰어난 경도, 내마모성, 열적 특성을 갖춘 박막을 생산하는 데 필수적인 세라믹 타겟의 정밀성을 경험해 보세요.

스퍼터링 타겟의 품질은 다음 4가지 중요한 핵심 요소를 갖습니다.

- Materials Purity: The higher, the better

- Gas Content: The lower, the better

- Density: The higher, the better

- Inner structure: 미세한 입자 크기를 가진 균일한 microstructure가 더 좋을 것입니다.

제조사에서 사용하는 주요 생산 기술은 진공 유도 용해 (vacuum induction melting) 및 열간 프레스 (hot pressing), 열간 등방 프레스(hot isostatic pressing, HIP)를 포함하며, 타겟 재료의 특성과 고객 요구 사항을 고려하여 적합한 공정을 선택합니다. 아울러, 풍부한 생산 경험과 성숙한 기술의 이점을 활용하여 제조사에서 제조한 스퍼터링 타겟은 낮은 가스 함량, 매우 높은 밀도, 약 100um의 평균 입자 크기를 가진 균일한 미세 구조를 가지며, 실 사용자가 우수한 성능의 박막을 얻을 수 있도록 보장합니다.

제조사는 대량 생산용 스퍼터링 타겟 외에도 R&D 목적의 소형 스퍼터링 타겟 생산 라인도 갖추고 있습니다. 1"~4" 직경의 다양한 크기를 제공하며, 최소 주문량(MOQ) 없이도 맞춤 제작과 공급이 가능합니다.

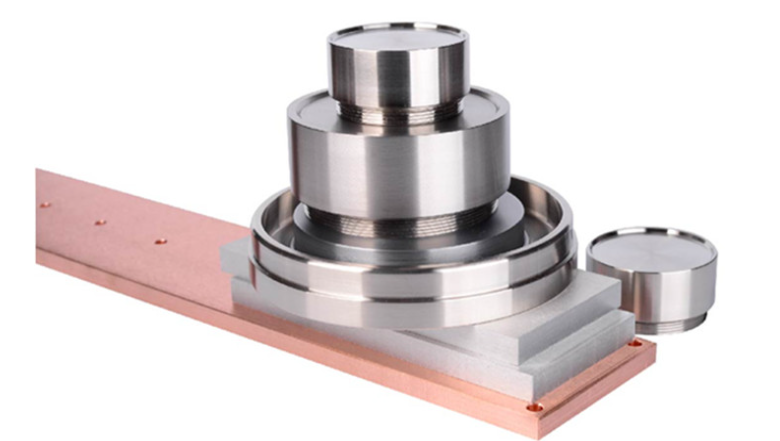

깨지기 쉽거나 소프트한 소재, 특히 세라믹 스퍼터링 타겟과 연성 금속 스퍼터링 타겟의 경우, copper backing plate에 Indium 본딩 서비스와 elastomer 본딩 서비스를 제공합니다. 백킹 플레이트는 타겟 소재를 지지하는 역할뿐만 아니라 스퍼터링 공정에서 발생하는 열을 방출(냉각)하고 마그네트론 냉각 시스템과 진공 챔버의 봉인 역할을 합니다. 세라믹 타겟의 경우, 직접 본딩할 경우 발생할 수 있는 균열 위험을 방지하기 위해 본딩된 타겟을 구매하실 것을 권장합니다.

Applications by Industry

Semiconductors & Electronics

-

IC fabrication, diffusion barriers, conductive and insulating films.

Display Technologies

-

Coatings for LCD, OLED, and touchscreens, including transparent conductors.

Solar & Renewable Energy

-

Thin-film solar cells (CIGS, CdTe), transparent conductive oxides (TCOs).

Optics & Photonics

-

Anti-reflective, mirror, and filter layers on lenses and precision glass.

Automotive & Aerospace

-

Wear-resistant or decorative coatings on engine parts, tools, and structures.

Medical & Research

-

Thin films for biosensors, diagnostic tools, and implant surface engineering.

Data Storage

-

Magnetic and protective coatings for hard drives and memory components.

PERIODIC TABLE OF THE ELEMENTS

1 H |

|

2 He |

|||||||||||||||||

3 Li |

4 Be |

|

5 B |

6 C |

7 N |

8 O |

9 F |

10 Ne |

|||||||||||

11 Na |

12 Mg |

|

13 Al |

14 Si |

15 P |

16 S |

17 Cl |

18 Ar |

|||||||||||

19 K |

20 Ca |

21 Sc |

22 Ti |

23 V |

24 Cr |

25 Mn |

26 Fe |

27 Co |

28 Ni |

29 Cu |

30 Zn |

31 Ga |

32 Ge |

33 As |

34 Se |

35 Br |

36 Kr |

||

37 Rb |

38 Sr |

39 Y |

40 Zr |

41 Nb |

42 Mo |

43 Tc |

44 Ru |

45 Rh |

46 Pd |

47 Ag |

48 Cd |

49 In |

50 Sn |

51 Sb |

52 Te |

53 I |

54 Xe |

||

55 Cs |

56 Ba |

57-71

|

72 Hf |

73 Ta |

74 W |

75 Re |

76 Os |

77 Ir |

78 Pt |

79 Au |

80 Hg |

81 Tl |

82 Pb |

83 Bi |

84 Po |

85 At |

86 Rn |

||

87 Fr |

88 Ra |

89-103

|

104 Rf |

105 Db |

106 Sg |

107 Bh |

108 Hs |

109 Mt |

110 Ds |

111 Rg |

112 Cn |

113 Nh |

114 Fl |

115 Mc |

116 Lv |

117 Ts |

118 Og |

||

|

|

|

||||||||||||||||||

*Lanthanoids |

57 La |

58 Ce |

59 Pr |

60 Nd |

61 Pm |

62 Sm |

63 Eu |

64 Gd |

65 Tb |

66 Dy |

67 Ho |

68 Er |

69 Tm |

70 Yb |

71 Lu |

|

|||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

**Actinoids |

89 Ac |

90 Th |

91 Pa |

92 U |

93 Np |

94 Pu |

95 Am |

96 Cm |

97 Bk |

98 Cf |

99 Es |

100 Fm |

101 Md |

102 No |

103 Lr |

||||