Indium bonding은 열전도도가 매우 우수하고 타겟으로부터 가장 효율적으로 열을 방출하므로, 스퍼터링 타겟을 접합하는 데 가장 좋은 방법입니다. 특수 타겟 물질의 경우, elastomer bonding이나 e-beam welding이 요구됩니다. 당사는 금속 타겟 재료와 복합 타겟 소재 모두에 대한 풍부한 target bonding 경험이 있으며, 재료의 특성과 작업 조건에 따라 고객에게 가장 적합한 본딩 솔루션을 제안합니다.

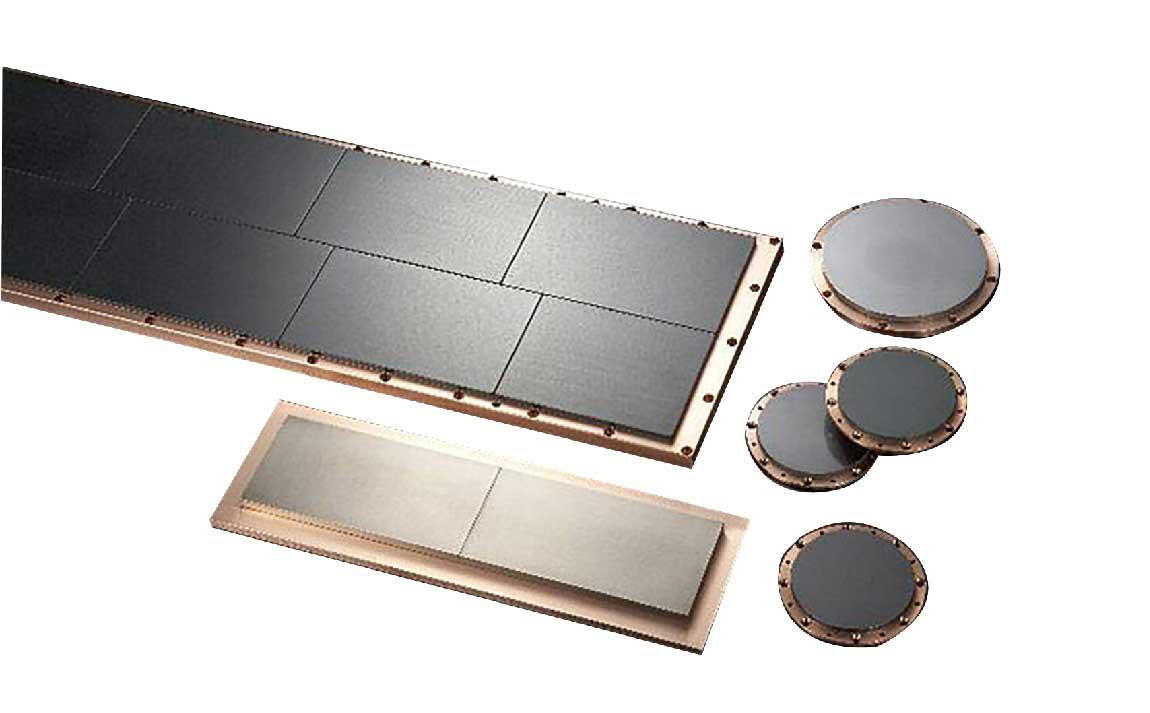

Bonding Service

For fragile and soft materials especially ceramic sputtering targets and soft metals sputtering targets, customer usually require to bond the target with backing plate. Because the bonding is not only a support to the targets materials, but also provide heat extraction(cooling) from sputtering process, as well as sealing from magnetron cooling system and vacuum chamber.

Indium bonding is the best method for bonding sputtering targets because it has the best thermal conductivity and is the most efficient at drawing heat away from the target. For special target materials , elastomer bonding or e-beam welding is required by customer.

We have abundant target bonding experience for both metallic target materials and compound target materials, and we suggest the best bonding solution to customer according to the materials properties and working condition.

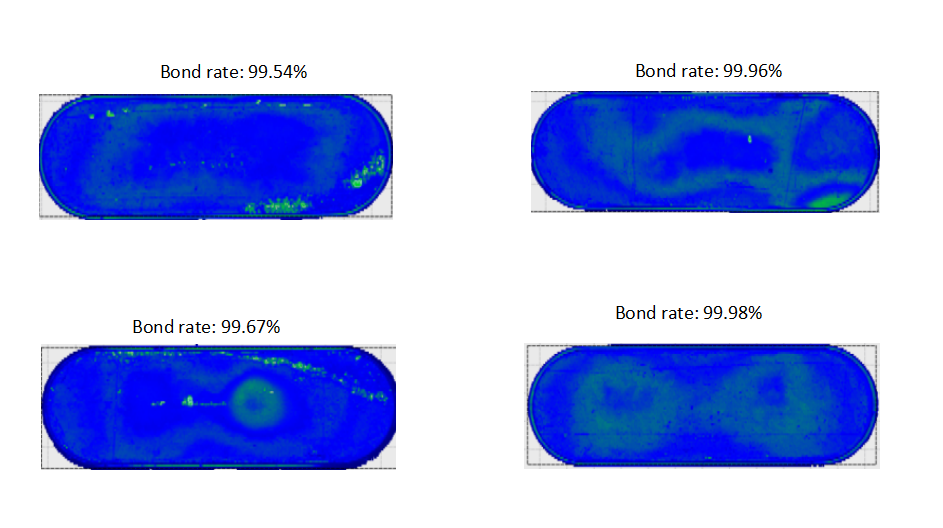

For indium bonding, the thickness of indium we controlled is 0.2-0.3mm, and we leave 0.2-0.3mm bonding gap between target tiles, and 95% bonding rate can be guaranteed form most targets bonding. C-scan report is available upon request.

We also customize backing plates according to customer request, pls contact us if you need it.

Selection of Backing Plate materials where the following factors must be considered:

Thermal Expansion of the Backing plate materials and Sputtering target.

- Electrical Conductivity

- Mechanical Properties to withstand the cooling water pressure and thermal cycling effect.

- Reusable

Backing plate materials commonly are made of by follow metals:

Oxygen Free Copper

The most commonly backing materials is is Oxygen Free Copper (OFHC) .This is readily available metal has good thermal conductivity and electrical conductivity, while also being easy to machine. Copper backing plates can be re-used, with care, twenty times or more.

Molybdenum Backing Plate

Molybdenum Backing Plate is suitable for high temperature bond , while copper may also oxidize badly or warp, and also matching with target materials where copper coefficient of expansion is mismatched, such as ceramics.

Aluminium Backing plate

Similarly for high thermal conductivity and matching to the target materials coefficient of expansion as well as suitable for diffusion bonding.

Stainless steel. Commonly used for Rotatable sputtering target where it provide a low cost recyclable backing tube.

Moreover, copper zinc (CuZn) alloy and copper chromium (CuCr) alloy backing plate are also available in our plant.