PVD는 금속, 세라믹, 플라스틱 등의 재료를 표면(기판)에 증착하고 박막을 형성하는 증발 코팅 기술입니다. 일반적으로 evaporation과 sputtering 두 그룹으로 나눌 수 있습니다.

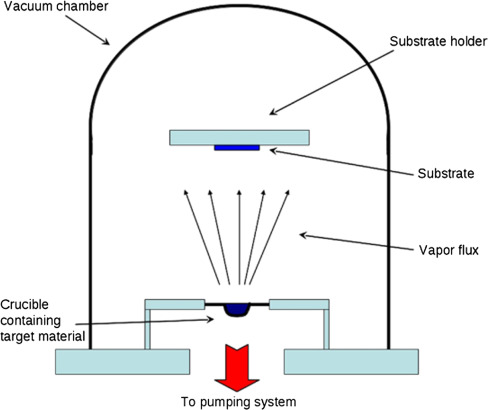

(주)연진에스텍은 PVD 코팅 재료의 전문 공급업체로서, 고객사의 용도에 가장 적합한 고품질의 evaporation target을 판매합니다. Evaporation process는 1×10−6 torr(1.3×10−4 Pa) 이하의 진공 챔버에서 타겟 물질을 증발시키고, 증발된 입자를 기판에 응축시키는 것으로 구성됩니다. 증착된 필름의 순도는 진공도와 증발 물질의 순도에 의존합니다. 고순도 증착 재료는 증착 공정에서 고품질의 증착막을 확보하는 데 중요한 역할을 합니다. 고순도 증착 재료는 전자빔 증착 및 박막 증착의 원료 물질 중 하나입니다.

당사 (주)연진에스텍은 thermal evaporation 및 증착 공정에 사용되는 고성능 물질을 다양한 형태와 순도로 맞춤형 크기의 제품을 판매합니다. 제공되는 형태에는 shot, 펠렛, granule, starter source, crucible liner, 막대 모양, wire, 랜덤한 크기의 lump 등이 있습니다.

Evaporation target 구매 문의 Contact 02)2675-0566 ~7, info@yeonjin.com

Evaporation Materials

당사는 모든 고객 요구 사항에 맞춰 다양한 순도와 크기의 고품질 원소 및 복합 증착 재료 뿐만 아니라 귀금속(금 Au, 이리듐 Ir, 팔라듐 Pd, 백금 Pt, 로듐 Rh, 루테늄 Ru, 은 Ag)과 비귀금속 박막 소재도 제공하고 있습니다.

모든 펠릿은 0.250" x 0.250" 또는 0.125" 또는 0.125" 크기로 제공되며, 고객의 독특한 요구 사항에 맞추는 커스터마이즈도 가능합니다. 사용 가능한 어떠한 순도의 gram, kilogram, troy ounce, pound, pellet, granules, shot, slug, spool, starter source로 공급할 수 있습니다. 재료의 크기, 조성, 희망하시는 순도를 알려주시면 고객의 요구 사항에 맞춰 제작해 드리겠습니다. 자주 요청되는 증착 재료도 빠른 납기로 공급할 수 있습니다.

저희는 코팅의 고순도, 재현성 및 균일성에 대한 고객의 우려를 해소해 줄 수 있는 증착 재료를 공급합니다. 이러한 재료는 다음과 같은 여러 장점을 제공합니다:

- 금속, 합금, 세라믹 등 다양한 소재로 제공됩니다.

- 최대 99.999% 순도의 초고순도

- 수율 향상

- 배치 간 일관된 소재 특성

- 다양한 형태로 공급

증착 물질의 화학적 구성에 따라 다음 3가지 유형으로 구분합니다:

- Metal evaporation materials

- Oxide evaporation materials

- Fluorides evaporation materials

증착 물질의 화학적 조성에 따라 다음 3가지 유형으로구분합니다:

- Pellets

- Starter sources

- Granules

- Tablets

증착 재료의 품질은 다음 세 가지 핵심 요소가 매우 중요합니다.

- Materials Purity: The higher, the better

- Gas Content: The lower, the better

- Density: The higher, the better

또한 당사는 금속 및 세라믹 보트(ceramic boat), 필라멘트, 도가니(crucible) 및 히터, e-beam crucible liner를 포함하여 thermal, e-beam evaporation을 위한 다양한 증착소스와 증착 펠릿을 제공합니다.

Thermal Evaporation Sources: Filaments, Basket Heaters, Boats and Boxes

Evaporation Pellets & E-Beam Source Used Crucibles

도가니는 전자빔 하스(e-beam hearth)에 증착물질이 쌓이지 않도록 하여 바스켓이나 호일 열원의 증착 용기 역할을 합니다. 도가니는 현대 실험실에서 중요한 아이템이며, 유리, 금속 등 다양한 소재의 생산에 중요한 역할을 합니다. 다양한 소재로 제작된 도가니는 고객의 요청에 따라 다양한 온도와 부식 저항성을 견딜 수 있습니다.

PERIODIC TABLE OF THE ELEMENTS

1 H |

|

2 He |

|||||||||||||||||

3 Li |

4 Be |

|

5 B |

6 C |

7 N |

8 O |

9 F |

10 Ne |

|||||||||||

11 Na |

12 Mg |

|

13 Al |

14 Si |

15 P |

16 S |

17 Cl |

18 Ar |

|||||||||||

19 K |

20 Ca |

21 Sc |

22 Ti |

23 V |

24 Cr |

25 Mn |

26 Fe |

27 Co |

28 Ni |

29 Cu |

30 Zn |

31 Ga |

32 Ge |

33 As |

34 Se |

35 Br |

36 Kr |

||

37 Rb |

38 Sr |

39 Y |

40 Zr |

41 Nb |

42 Mo |

43 Tc |

44 Ru |

45 Rh |

46 Pd |

47 Ag |

48 Cd |

49 In |

50 Sn |

51 Sb |

52 Te |

53 I |

54 Xe |

||

55 Cs |

56 Ba |

57-71

|

72 Hf |

73 Ta |

74 W |

75 Re |

76 Os |

77 Ir |

78 Pt |

79 Au |

80 Hg |

81 Tl |

82 Pb |

83 Bi |

84 Po |

85 At |

86 Rn |

||

87 Fr |

88 Ra |

89-103

|

104 Rf |

105 Db |

106 Sg |

107 Bh |

108 Hs |

109 Mt |

110 Ds |

111 Rg |

112 Cn |

113 Nh |

114 Fl |

115 Mc |

116 Lv |

117 Ts |

118 Og |

||

|

|

|

||||||||||||||||||

*Lanthanoids |

57 La |

58 Ce |

59 Pr |

60 Nd |

61 Pm |

62 Sm |

63 Eu |

64 Gd |

65 Tb |

66 Dy |

67 Ho |

68 Er |

69 Tm |

70 Yb |

71 Lu |

|

|||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

**Actinoids |

89 Ac |

90 Th |

91 Pa |

92 U |

93 Np |

94 Pu |

95 Am |

96 Cm |

97 Bk |

98 Cf |

99 Es |

100 Fm |

101 Md |

102 No |

103 Lr |

||||