Instruments to which this note applies: Biocal 2000, Biocal 4000

Target use: Research and Quality Control of processing and preservation methods used for fresh cut fruits and vegetables.

Introduction

신선한 과일과 채소는 특히 방부제가 거의 없는 신선한 제품으로 소비자들에게 제공되기 때문에 부패하기 쉬운 경향이 있습니다. 절단, 파쇄 또는 박리와 같은 공정은 변색, 갈변 및 질감 또는 맛의 변화가 일어나기 때문에 소비자들의 변심이 생길수 있습니다. 기계적 변형에 의한 상처로 소비자들의 변심이 높은 비율로 나타날수 있고 이는 부패성과 관련있는 것으로 알려져있습니다[1}. 이 호흡 속도는 등온 열량측정 곡선에서 쉽게 볼 수 있습니다. Calmetrix Biocal과 같은 등온열량 측정기에서는 절단, 박피 또는 파쇄로 인한 다양한 유형의 상처에 의한 효과 뿐만 아니라 처리방법에 의한 부패를 최소화하기 위해 호흡 속도에 대한 특정 보관 조건, 온도 및 다른 가능한 보존 방법을 연구 할 수 있습니다.

결과는 기술자의 외부 개입없이 지속적으로 측정할 수 있고 실험 종료시 쉽게 검색하고 분석할 수 있습니다. 이것은 등온열량측정법이 다른 식품에 발효가 어떻게 진행되는지 평가할 수 있는 편리하고 효과적인 도구가 되며, 단순히 등온열량측정 곡선을 비교하여 온도, 스타터 농도 등의 함수로 발효 속도를 쉽고 빠르게 비교할수 있습니다. 125ml 플라스틱이나 스테인리스 스틸 엠플을 사용하는 Biocal과 같은 큰 샘플셀 을 이용하는 열량계를 사용하면 과일과 채소 혹은 다른 모양과 크기로 잘린 과일과 채소 그리고 식품과 같이 연구할 수 있는 식품의 범위가 늘어날 것입니다.

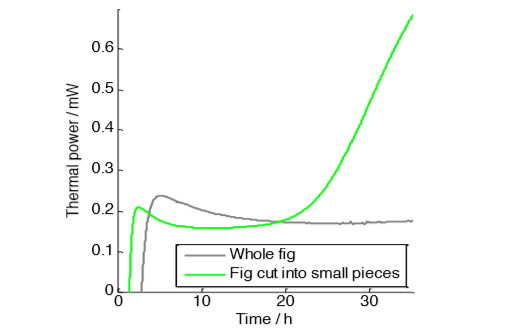

이 Application Note는 무화과, 과일 전체나 조각 모두에서 발생하는 호흡으로부터 열 변화를 보여줍니다.

Test Protocol

In a Biocal 2000 calorimeter at 23 °C, one sample channel contained a whole fresh fig (37.5 g), while the other channel contained a similar fresh fig (34.5 g) cut in 10 mm pieces.

Results and Interpretation

Both samples show similar respiration at about 0.2 mW for about 15 h. After this, the heat production from the cut fruit starts to increase in an “exponential” way. When the vials were opened after the experiment, the cut fig was heavily molded.

The rate of respiration of 0.2 mW for a fruit with a mass of about 35 g, corresponds to about 6 µW/g fresh mass.

The microbiological activity shows – as it commonly does – an accelerating phase. This is usually termed the “exponential” phase, but perfectly exponential behavior is mainly seen in liquid cultures. In the present case we have surface growth of molds (and possibly also other organisms, e.g., bacteria), and the rate of such a process is not only influenced by how fast the organism can grow, but also by such factors as nutrient availability and crowding on the surface.

Both figs and molds are aerobic organisms: in contrast to yeast and many bacteria, they need oxygen for their metabolism. If we assume that all the measured heat comes from aerobic metabolism (respiration) we can calculate how much oxygen is consumed during the experiment, as the heat or respiration is known to be about -455 kJ/mol (O2) [2]. The whole fig produces about 20 J during the measurement; this corresponds to 44 µmol of consumed oxygen. For the cut fig the total heat is about 35 J, corresponding to about 77 µmol oxygen. Both these amounts of oxygen are quite low; the air in a 125 mL ampoule with a fig can support respiration producing about 400 J of heat. It is important to not run out of oxygen in respiration experiments, but in this case the respiration is very low, so that the oxygen level only dropped from 21% to about 20% during the measurement.

Conclusion

Isothermal calorimeters such as Biocal 2000 and Biocal 4000 are an effective and easyItoIuse tool to measure respiration rate due to wounding of fresh fruits and vegetables. The method described in this Application Note can be used for example for small whole fruit, as well as fresh-cut produce in general and to study the metabolic response to various cutting or peeling methods.

References

- Bolin, H.R. and Huxsoll, Effect of preparation and storage parameters on quality retention of salad-cut lettuce. Journal of Food and Science 5691(1991) 60-67.

- Hansen, L. D., C. MacFarlane, et al. (2004). "Use of calorespirometric ratios, heat per CO2 and heat per O2, to quantify metabolic paths and energetics of growing cells." Thermochim Acta 422: 55-61.

- Wadsö, L. and F. Gómez Galindo (2009). "Isothermal calorimetry for biological applications in food science and technology." Food Control 20(10): 956-961.