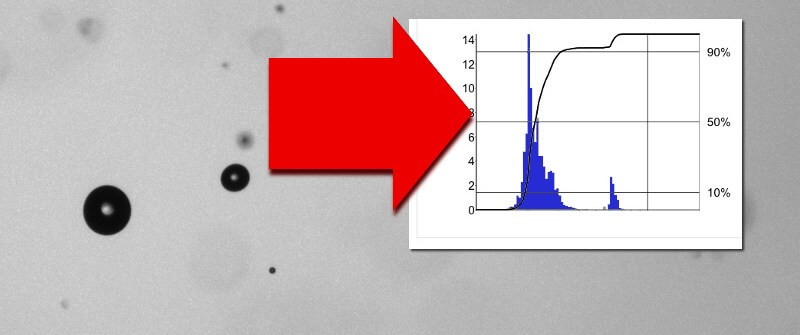

This is the measurement of the sizes and shapes of particles, droplets or bubbles using image-based analysis. Our VisiSize real-time droplet measurement systems, capture high speed images of a cloud of particles, sprays (e.g. for water droplet size measurement), or flow of bubbles to obtain the size distribution of the drops. In addition, to measure particle diameter, Oxford Lasers measurement systems also provide real-time shape and velocity analysis.

- Real-time spray droplet size measurement

- Measuring the speed and direction of particles or droplets

- Measurement of individual particles

- Capture images of the particle or droplet "on the fly"

- Non-intrusive measures

- In-Situ Measurements

- Direct reports, real-time results

Droplet spray size with speed and direction

VisiSize's unique sizing algorithms allow simultaneous measurement of particle size as well as speed and direction. This means that you can correlate the size of particles or droplets with their velocity. Find out how the speed of your spray relates to size and then work on those parameters to achieve the desired results. Find out why VisiSize is an alternative to PDPA systems.

Non-Intrusive Live Analysis

Our powerful on-line analysis systems measure particle diameter, shape, and diffusion rate for solids, liquid sprays and gases suspended in any transparent medium. No other droplet sizing system is as intuitive to use as direct imaging equipment.

Intuitive in use

If you know how to use a camcorder or digital camera, you will know how to use a VisiSizer measurement system. There is no complex alignment or calibration procedure, plus the VisiSize software manages the most delicate parts for you. Find out how the use of our systems is easy to learn through our software.

Image-based shape measurement

captured with a Visisize system.

You see on the right, the first “in flight” image of the output of an agricultural air inclusion nozzle. In this image, taken from a VisiSize system, not only the non-spherical water drops are visible, but also the air bubbles within them. Other measurement techniques like DPA or laser diffraction can measure the water drop but without stipulating that you have done so, so you do not get the measurement of air inclusions.

A powerful research tool

VisiSizer systems are also very powerful Imaging systems. Beyond capturing images for measurement, the systems are able to visualize the rupture and the process of drop formation. This provides very valuable insight into the effects and problems of the nozzle. Combined with image-based quantitative diameter data, sizing is an extremely powerful tool for Research and Development.

Applications

- Fuel Injector Characterization

- Characterization of agricultural spraying

- Paint sprays

- Pharmaceutical devices (MDIs, Dry Powder Inhalers, nasal sprays)

- Characterization of Nozzles

- Firefighting / extinguisher

- Characterization of bubble columns

- Bubble column characterization

- Live measurement of solid particles in the production process