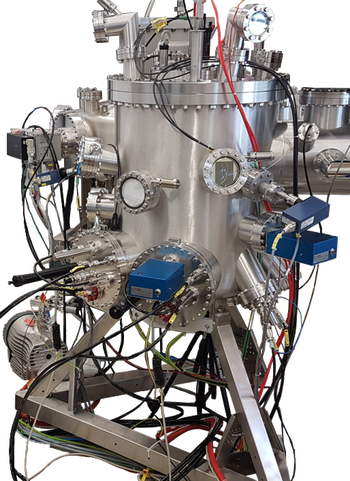

State-of-the-art MBE system for research and production

- Applications: III/V, II/VI or other material heterostructures

- 12 source ports

- Wide range of source options, e.g. effusion cells, valved sources etc.

- Substrate sizes 4", 6" or 3x2"; face-down wafer geometry

- Automated wafer transfer

- Strong UHV pumping system

- LN2 cooling shroud

- In-situ characterization capability

- Professional support by PhD MBE experts

General Information

The OCTOPLUS 600 system has been developed for the growth of high quality III-V heterostructures on multi wafer 3x2 inch or single wafer 4 inch or 6 inch substrate. The MBE chamber is equipped with up to 12 effusion cells and valved crackers for deposition. The substrate manipulator applies to pyrolytic graphite or alternatively tungsten or tantalum heaters. The OCTOPLUS 600 MBE system is field-proven and ideally suited for III/V, II/VI and other heterostructure growth for applications in research and production processes.

Outstanding features of the OCTOPLUS 600 are the high reliability and versatility of the system.

The standard version of the OCTOPLUS 600 comprises 12 radially arranged source ports, 3 further source ports can be added on request. A rapid pump-down load lock chamber with wafer magazine, a heated station and the fully automated central transfer allow easy substrate introduction and handling.

The OCTOPLUS 600 is available with an EBV option to replace some of the effusion cell flanges and instead mount horizontal electron beam evaporators.

With this option the OCTOPLUS 600 can be used as a dedicated Si-Ge MBE with two horizontal 100 cm³ EBV sources.

At Dr. Eberl MBE-Komponenten GmbH we have very detailed knowledge in the group IV elements C, Si and Ge MBE and are happy to discuss such an application in further detail with you.

A version with one horizontally mounted 6-pocket electron beam evaporator allows working with layers containing high temperature materials such as e.g. W, Ta, Nb, Mo, Pt. This can be used for metallization, growth of superconductors or even transition metal dichalcogenides.

Options for OCTOPLUS 600

- Additional load-lock, heated station, or buffer chamber

- Manual wafer transfer with linear transfer tunnel system (up to 4inch wafer)

- Or fully automated wafer transfer with central distribution chamber (up to 6inch wafer)

- Wide range of components like effusion cells, e-beam-evaporators, sublimation sources, valved cracker sources, gas sources, manipulators

- Software/hardware control system

- Pumping system (cryopumps, ion getter pumps, etc.)

- In-situ characterization tools, e.g. RHEED, BFM, Quartz Crystal Microbalance (QCM), Pyrometer

Technical Data

|

Size of deposition chamber |

600 mm I.D. |

|

Base pressure |

< 5x10-11 mbar |

|

Pumping |

TSP, ion getterpump, cryopump and/or turbopump |

|

Cooling Shroud |

LN2 or other cooling liquid on request |

|

Substrate heater temperature |

up to 800°C, 1000°C or 1200°C |

|

Substate size |

4", 6" or multi-wafer 3x2" |

|

Bakeout temperature |

up to 200°C |

|

Source ports |

12 ports DN100CF |

|

Source types |

effusion cells, e-beam evaporators, sublimation sources, valved cracker sources, gas sources |

|

Shutters |

soft-acting linear shutters with low flux transient |

|

In-situ monitoring |

ion gauge, QCM, pyrometer, RHEED, QMA |

|

Sample transfer |

automated transfer with wafer face-down geometry |

|

Load lock |

magazine with 10 substrates turbo-pumped |

|

MBE control software |

Tiny Tusker |

|

Service |

system installation and acceptance testing |

|

MBE training |

by MBE experts |

Examples for applications and corresponding sources

|

Plasma Sources |

E-Beam |

||||

|

III/V |

Ga, In, Al |

C, Si doping |

As, P, Sb |

|

|

|

II/VI |

Zn, Cd, Be |

|

S, Se, Te |

N-doping |

|

|

IV |

Ge, Sn, Pb |

B, P, Sb doping |

|

|

Si, Ge |

|

GaN |

Ga, In, Al |

|

|

N |

|

|

Metals |

Cu, Al, Ni, Co, ... |

|

|

|

Pt, Ta, Pd, Mo, W |

|

Topological Insulators |

Ge, Sn, Te, Bi, GeSb |

|

Se, Te |

|

B |

|

Graphene / Silicene |

|

C, Si |

|

|

|

|

Oxides |

Fe, Ni, Mn, Bi, Eu, |

|

|

O |

|

|

Thin Film Solar Cells |

Cu, Ga, In, Zn, NaF, |

|

S, Se |

|