Home

> 진공증착시스템 (Vaccum Decposition System)

> AJA 진공증착시스템 카테고리별 디테일

> HV/UHV 진공증착장비

> Sputtering Systems (HV, UHV)

> 연구개발 및 생산용 스퍼터 소스

AJA International사는 1991년 이래, 특별히 설계된 100여 가지가 넘는 다양한 유형의 마그네트론 스퍼터링 소스를 개발하여, 기판 형상, 연구개발 및 품질관리, 생산량, 챔버 구성, 타겟 재료, 필름 사양에 따른 직사각형, 원형, 원통형, 삼각형, 회전 마그넷 버전의 연구개발용 HV/UHV Magnetron Sputtering Source와 생산용 HV Magnetron Sputtering Source를 제공하고 있으며, 당사 (주)연진에스텍은 AJA의 진공증착 소스를 독점적으로 판매, 서비스합니다.

PRODUCTION MAGNETRON SPUTTERING SOURCES (HV)

MORE DETAIL

STX & STXL Series Sources

-

STX Series Circular Sources 5"-12"

-

STXL Series Rectangular Sources 75mm x 300 mm to 150 mm x 1.0 m

Nautilus Rotating Magnet Sources

-

Open magnet architecture flexibility for tailored uniformity optimization

Cylindrical Target Sources

-

For 360° immersion coating

Triangular Target Sources

-

For 200 mm wafer batch coating

R&D MAGNETRON SPUTTERING SOURCES (HV AND UHV)

MORE DETAIL

Stiletto Series HV Sources

- Stiletto Series Circular Sources 1"- 4"

- Stiletto Series Rectangular Sources

- End mounted - for tube coating

- Turrets and cluster flanges

A300 Series UHV Sources

- A300-XP UHV Sources 1.5"- 6"

- A310 1" UHV Sources

- CTM Series Sources

- Turrets and cluster flanges

A3CV Series UHV Sources

- Convertible target modules

- Specialty configurations

Unique Modular Magnet Array

AJA사의 마그네트론 스퍼터링 소스 (Magnetron Sputtering Source)는 냉각수로 부터 완전히 격리된 독특한 "모듈형 마그넷 어레이 (modular magnet array)"를 특징으로하여 마그넷의 열화 (magnet deterioration)와 이에 따른 소스 성능 저하 (degradation)를 제거합니다. 이러한 설계는 내부 마그넷 배열 (magnet arrangement)에 대한 접근을 허용하므로 동일한 소스 사용에 따른 다음과 같은 장점이 있습니다:

- Operated as a balanced magnetron

- Configured for maximum target utilization

- Configured for high or low rate sputtering

- Operated in a variety of unbalanced magnetron configurations

- Changed for uniform or intentionally non-uniform depositions

- Configured for high or low electron energies as they arrive at the substrate surface

- Operated with thick magnetic material targets

- Optimized for easy magnetic target removal and replacement

Typical Performance

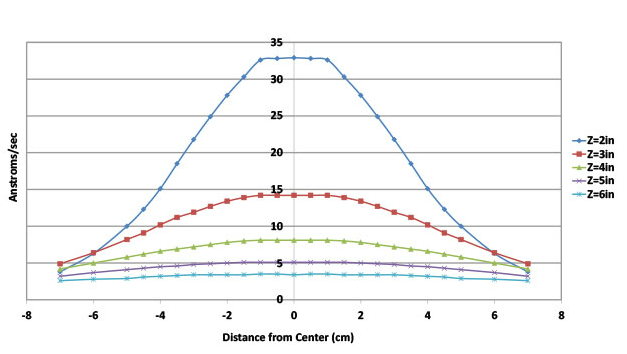

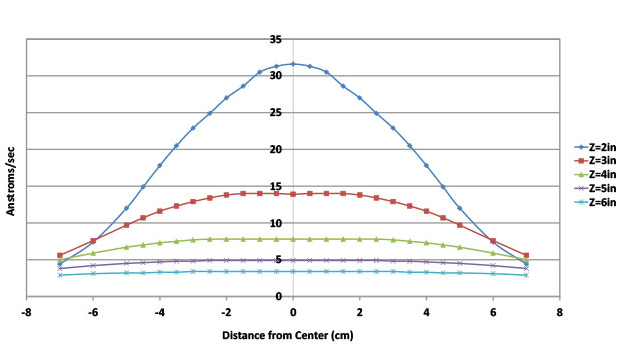

This data is for 2" UHV and HV magnetron sputter sources configured in an unbalanced mode for maximum rate, target utilization and film density. Deposition orientation is direct and shown at different working distances. Operating Pressure was 3.0 mTorr and a Cu target was run at 100 Watts. Uniformity over a 4 cm diameter substrate was ±2.9% at 3", ±1.9% at 4" and ±1.0% at 5".

This data is for 3" UHV and HV magnetron sputter sources configured in an unbalanced mode for maximum rate, target utilization and film density. Deposition orientation is direct and shown at different working distances. Operating Pressure was 3.0 mTorr and a Cu target was run at 100 Watts. Uniformity over a 4 cm diameter substrate was ±0.7% at 3", and less than ±0.1% at 4". Uniformity over an 8 cm diameter substrate was ±3.25% at 4", ±2.05% at 5" and ±1.48" at 6".

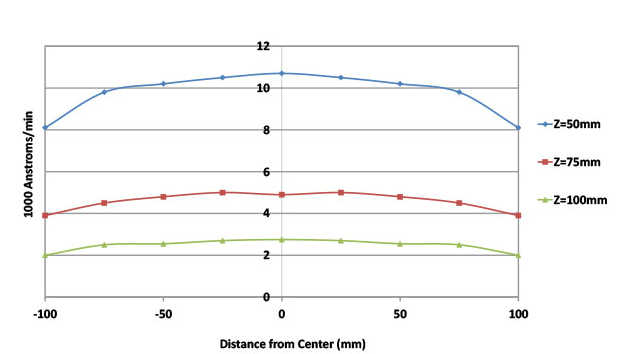

The data shown above is measured at 3 working distances over the ST2080 in the long direction. The source was tested with a Cu target at 4 mTorr and running at 1400 W (2505 mA, 558 V). Uniformity over 6" at a 4" working distance is ±3.2%.

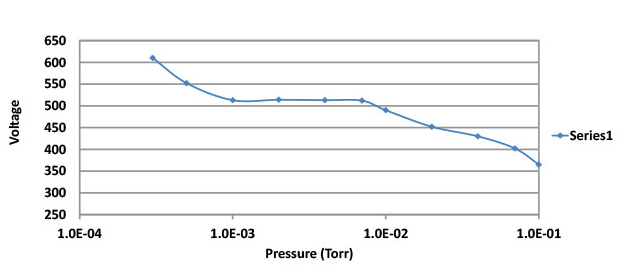

Discharge Voltage as a function is shown for both 2" sources running at 200 W DC power.

Typical Features

- Modular magnet array isolated from cooling water

- Magnetic material sputtering of thicker targets

- Easy removal of larger magnetic targets

- Integral gas injection and chimney system

- Efficient target cooling with no vacuum/water seals

- Clamped target mounting for optimal heat transfer

- RF & DC compatibility

- Rugged HV construction

- Operating pressure: (0.3 mTorr - 1.0 Torr)

- In-situ tilt or manual tilt for optimum uniformity

- Custom versions available

- Source/power supply/target packages available

Typical Applications

- CD/DVD disk coatings (e.g. reflective, phase change)

- Semiconductor

- Conductive metal / resistive metal / Insulating Films

- Transparent electrical conductors (e.g. ITO)

- Optical communications applications (e.g. pump lasers)

- Wear resistant films

- Lens coatings (reflective/anti-reflective/ hard/color)

- Precious metals (for maximum target utilization)

- Thin film sensors

- Coatings for surgical/medical implements & implants

- Magnetic storage media and heads (HD, GMR , TMR)

- Photovoltaic thin films (solar cells)