-

RT - 1000°C with liquid nitrogen cooling option

-

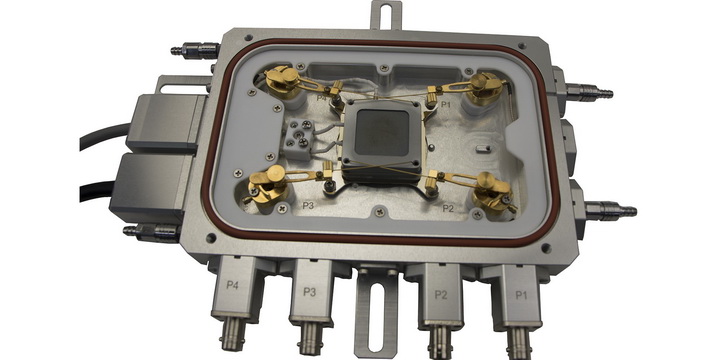

16 mm × 16 mm sample area

-

4 independent electrical probes with manual positioning

-

Optional triaxial connection

-

Optional extra feedthrough

THERMAL FEATURES

|

Temperature Control |

mK2000 with programmable precision switching PID method |

|

Thermal Block |

Ceramic for high temperature work |

|

Sample Thermal Cover |

Removable Inner sample cover with additional window |

|

Temperature Minimum |

30°C (active cooling not available) |

|

Temperature Maximum |

1000°C |

|

Temperature Sensor |

S type thermocouple |

|

Maximum Heating Rate |

+200°C per minute below 800°C |

|

Minimum Heating and Cooling Rate |

±0.01°C per minute |

|

Temperature Resolution |

0.2°C |

|

Temperature Stability |

±1°C |

|

Power supply |

Universal power input |

|

Software |

Windows software to record and export temperature-time data |

ELECTRICAL FEATURES

|

Probe Positioning |

Manual cantilever probes independently positionable to any point of the sample area before sealing chamber |

|

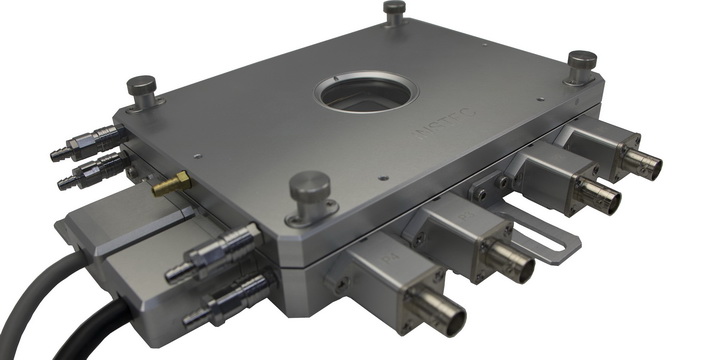

Connectors |

Coaxial, floating, or triaxial BNC connectors Optional extra feedthrough |

|

Sample Surface |

Grounded, floating, or triaxial options |

OPTICAL FEATURES

|

Optical access |

Reflection and transmission capability |

|

Minimum Objective Working Distance |

9.6 mm |

|

Minimum Condenser Working Distance |

15.0 mm (Only HS1000G-PM) |

|

Top Aperture |

38 mm diameter |

|

Top Viewing Angle |

±61.5° from normal |

|

Transmission Aperture |

2 mm diameter (Only HS1000G-PM) |

|

Bottom Viewing Angle |

±11.3° from normal |

STRUCTURAL FEATURES

|

Sample Area |

16 mm x 16 mm |

|

Chamber Height |

7.6 mm |

|

Atmosphere Control |

Gas purging capability to control humidity, condensation, and oxidation |

|

Frame Cooling |

Integrated frame cooling with optional chiller system |

|

Window and objective protection |

Cooling by purge air |

|

Mounting |

Horizontal and vertical mounting capability |

|

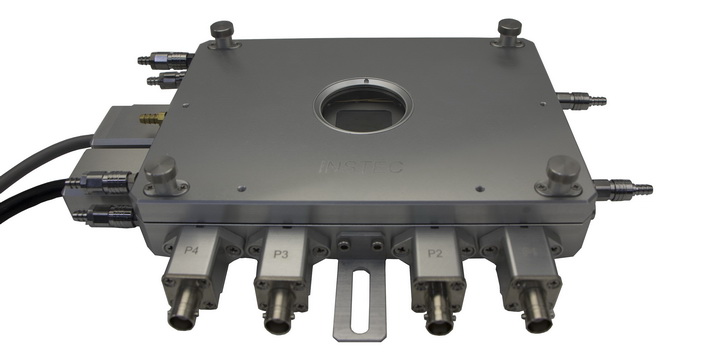

Frame Dimensions |

180 mm x 130 mm x 30 mm |

|

Weight |

1500 g light-weight aluminum body |