Workflow for the determination of the thermal conductivity (flucon fluid analysis)

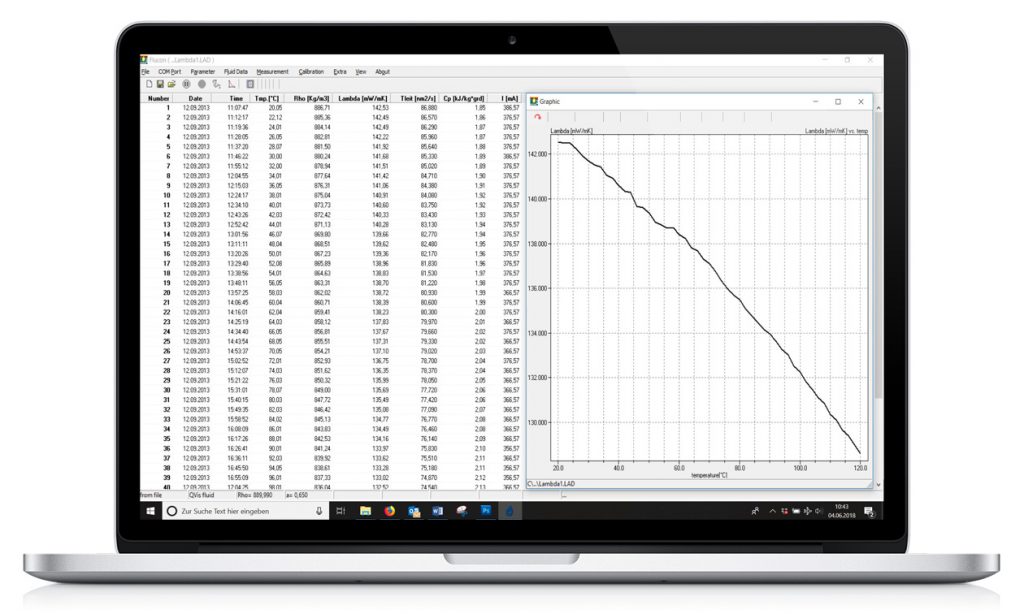

flucon not only offers their portable LAMBDA measuring system but also in-house fluid analysis in our own high pressure laboratory. Customers may send in small samples (300 ml) of the fluid they would like to have tested and then the following steps will be performed:

- Laboratory measurement of the thermal conductivity as a function of temperature and pressure using a transient measuring method preventing an influence of convective flow of heat on the measuring result

- Mathematical description of the pressure/temperature-dependant thermal conductivity

- Graphical data preparation

Fundamentals of measuring λ

Stationary vs. instationary method

There are two ways of measuring thermal conductivity: the stationary and the instationary method. The stationary method is principally simpler as it proceeds from a constant temperature level, whereas the instationary method takes the problem of a changing temperature field into account. There is an advantage resulting from this extra effort however: the instationary method provides measuring results for the thermal conductivity much faster and the results are less influenced by convection.

The effects of convection for the stationary method

According to POLTZ the stationary method is seriously hampered by the fact of thermal conductivity induced by convection. In Tuluol, for example, an average flow rate of only o.01 mm/min leads to a deviance of about 1% in the data obtained for the thermal conductivity due to free convection. Therefore, POLTZ concludes that the stationary method, especially in an experimental set-up where the thick layers are concerned, cannot provide measuring data without a noticeable influence of convection. Furthermore, great care must be taken to avoid any kind of forced convection, such as would be caused by vibration of the measuring apparatus.

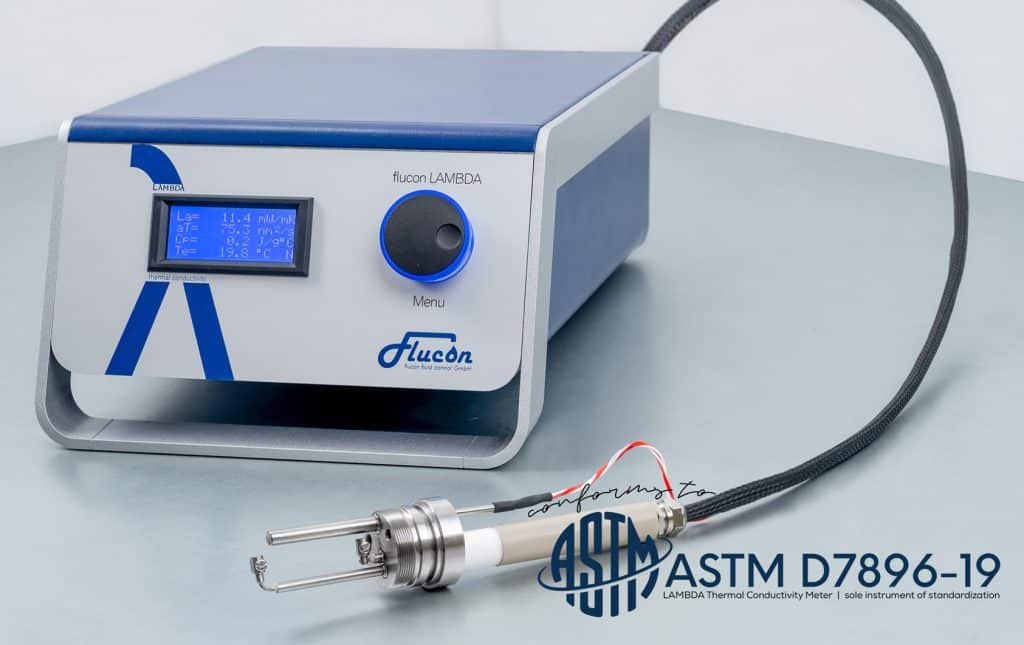

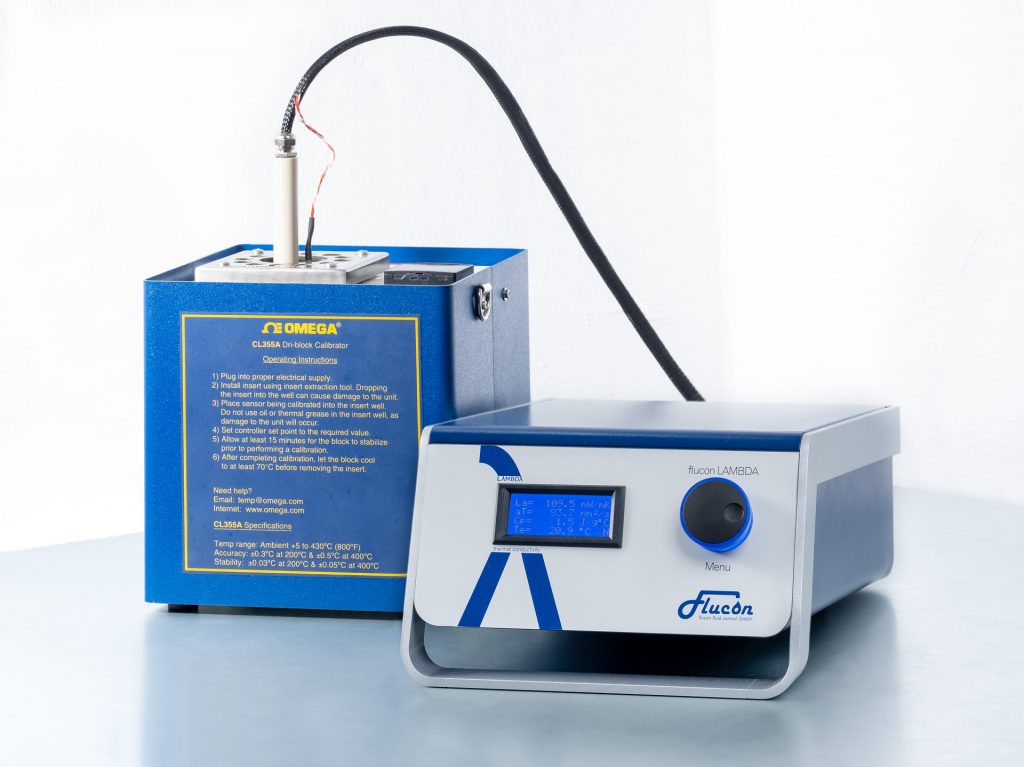

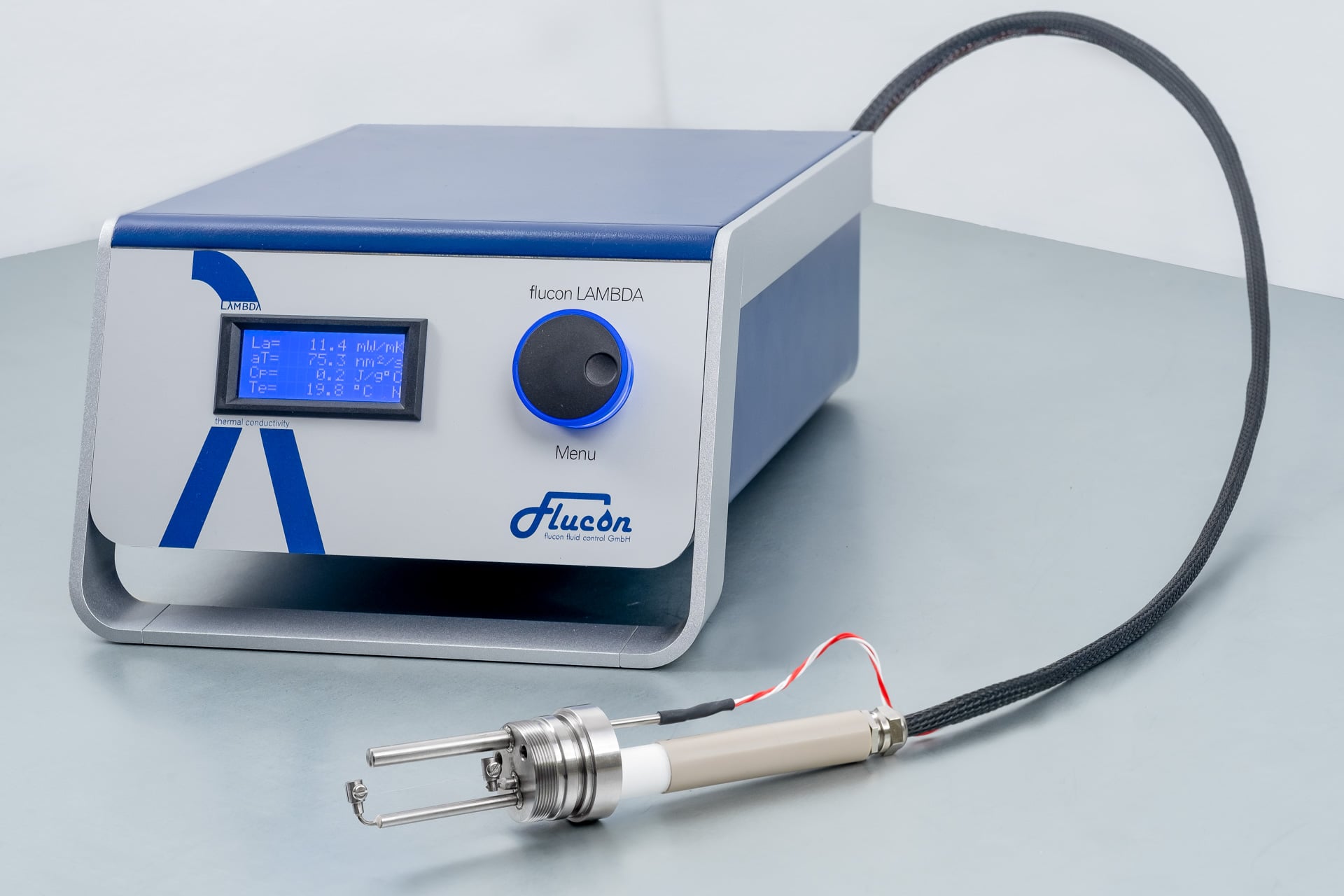

Measuring lambda. With LAMBDA.

The LAMBDA Thermal Conductivity Meter developed by flucon will give you the advantages of the fast instationary transient hot-wire method while at the same time excluding the influence of convection in the measuring process. This is achieved by computational processing of the data obtained within very short periods of time (approx. 800 ms) which in turn leads to a very short over-all duration of the test process (approx. 60 s).

The hot-wire of the LAMBDA serves as the source of heat and as the transducer at the same time. In order to raise the temperature, the hot-wire is subjected to a constant measuring current; as the surrounding medium warms up, the resistance of the hot-wire will change in accordance with the thermal viscosity of the surrounding medium. Thus the change of voltage in the hot-wire indicates the change of temperature taking place in the surrounding medium.