Cost effective, Desktop Plasma ALD

Desktop Plasma ALD System

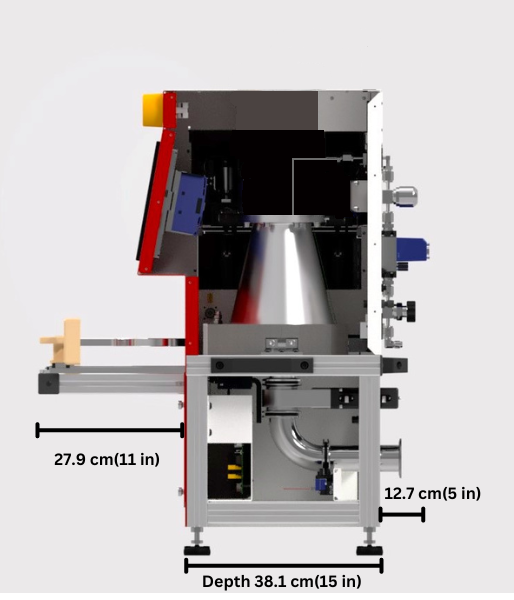

The AT650/850P is a compact desktop plasma ALD system that delivers high-quality films with deep penetration. The system can process smaller wafers up to 8 inches for the AT 850P. It features a hollow cathode plasma source and a 60 MHz RF generator, providing high electron density and low plasma damage, suitable for applications requiring precise film characteristics.

FEATURES

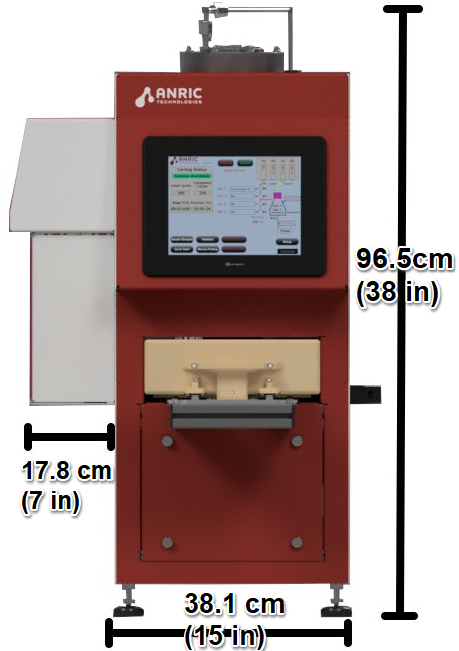

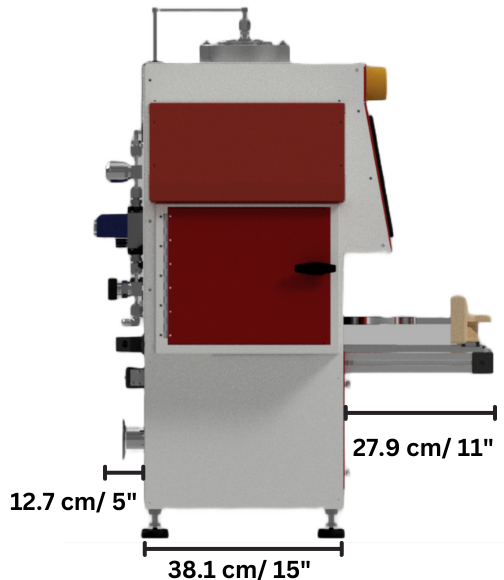

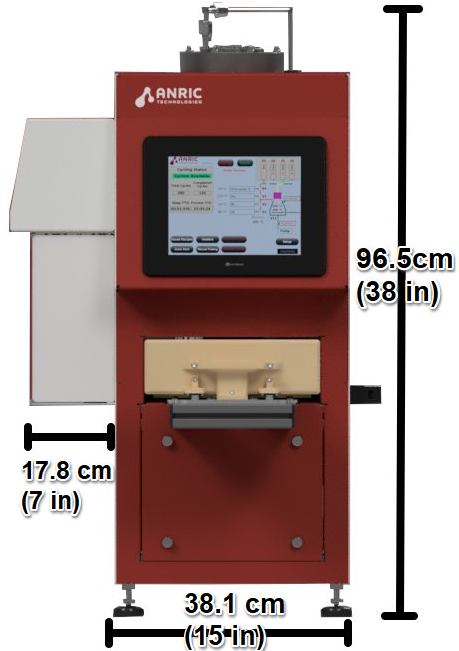

- Small Footprint (38.1 cm; 15″ across) Desktop Plasma ALD

- High efficiency, remote 300 watt hollow cathode source and 60 MHz RF generator

-

Features: low oxygen contamination, high electron density, low plasma damage

-

- Integrated matching network

- Accommodates samples of 6″ diameter with optional customizable chucks.

- Warm walled aluminum chamber with heated sample holder from 40 – 450 °C (580 °C available)

- 4 organometallic precursors can be heated to 175 °C.

- Up to 4 oxidant/reductant sources each with ultrafast MFCs (2 standard)

- High temperature compatible fast pulsing ALD valves with an ultrafast MFC and

integrated inert gas purge - High exposure available with static processing mode

SPECIFICATION

- Substrate temperatures from 40 to 450 °C ± 1 °C (580 °C optional) ; Precursor temperatures from RT to 175 °C ± 2 °C (w/ heating jacket)

- Small footprint (15″ by 15″), bench top installation and fully cleanroom compatible

- Simple system maintenance and low utilities cost.

- Streamlined chamber design and small chamber volume

- Fast cycling capability and high exposure, deep penetration processing available

- Full HW and SW interlocks for safe operation even in multi-user environment.

OPTIONS

- Customized chuck/platen

- High temperature chuck up to 580 °C

- QCM (Quartz Crystal Microbalance)

- Additional Counter reactant lines (MFC controlled) – up to 2 additional

- Optional bubbler available with pressure boost technology

- Load lock (or glove box integration)

- External control – PC/software link (allows programming and running, remotely)

- Higher than standard pressure regime

-

Customized systems

FACILITIES

For detailed instructions see our presentation and video instructions: “AT650P Installation and Start-up“

- N2 purge gas should be >99.9995% with a shutoff valve (regulated to 10 – 30 psi, metal sealed).

- Input line is 1/4 female VCR compression fitting

- Attach > 99.9995% nitrogen (UHP) purge gas via 1/4″ metal line to the 1/4″ compression fitting on back

- Attach 90-110 psi CDA (clean dry air) via 1/4″ polyethylene tubing or metal line to the other 1/4″ compression fitting marked CDA (Clean Dry Air)

- Min 19.5cfm wet pump (**PTFE vacuum fluid (like Fomblin) required) (Dry pump is optional)

- NW40 (1.5″) connection and also exhaust line (with > 5cfm draw)

- Greater than 1 meter should use NW50 exhaust line

- Precursor’s attach via female VCR elbows (always use new gaskets).

- Elbow: 1/4″ gasket first (with gloves on)

- For precursor attachment please refer to “AT650P Tool and Software Operation”

SOFTWARE

For detailed instructions see our presentation and video instructions: “AT650P Installation and Start-up“

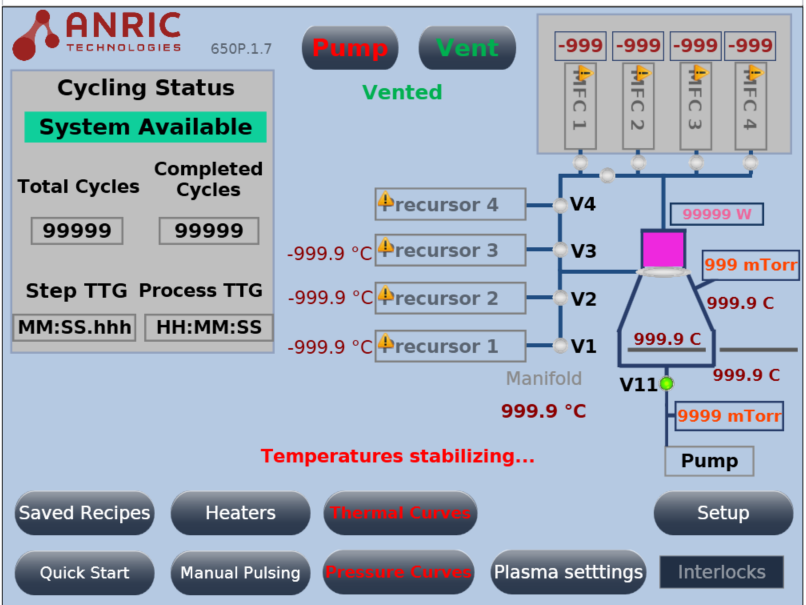

- Human Machine Interface (HMI) PLC system with a 10” touch screen panel

- Advanced controls suitable for the deposition of standard ALD cycles as well as e.g. Nanolaminates, Doped Thin Films and Ternary Thin Films

- Recipe database for high quality, tested processes

- Custom recipe input screen

- Real time display of process status

- Individually programmable heated source temperatures

- Built-in pulsing sequences for ternary compounds and nano-laminates

- Quick running with simple questions to get user going

- Input subcycles and overall cycles