| THE HEX SERIES |

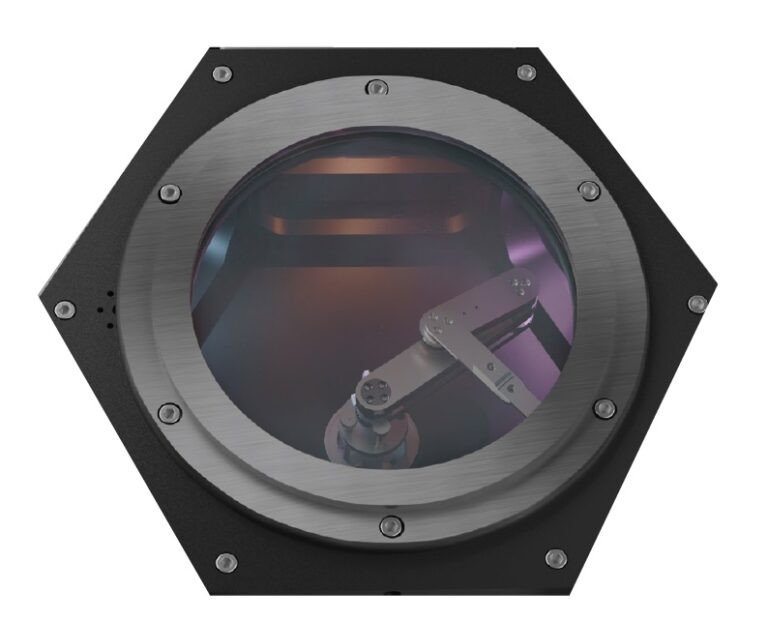

PVD Cluster Systems

Staying true to our philosophy of flexibility and upgradability, the HEX PVD Cluster System from Korvus allows users to begin with a single HEX-L chamber, and then connect further HEX-L chambers later on for in-vacuum transfer of samples between them.

Korvus Technology’s PVD cluster system provides a solution to make the thin film deposition process more flexible, cost-effective and efficient.

Our HEX PVD systems are unique in their versatility.

The highly modular design prioritises customisation and flexibility for manufacturers and researchers using thin film deposition.

The HEX PVD cluster system produces thin films sustainably and efficiently. With the HEX PVD cluster system, you can:

- Develop multi-layers of different classes of materials

- Separate stages of thin film deposition processes into different chambers

- Expand PVD capacity with more deposition chambers, sources and tools

- Future proof your research

KORVUS TECHNOLOGY

Thin Film Deposition

The HEX PVD cluster system produces thin films sustainably and efficiently. With the HEX PVD cluster system, you can:

- Develop multi-layers of different classes of materials

- Separate stages of thin film deposition processes into different chambers

- Expand PVD capacity with more deposition chambers, sources and tools

- Future proof your research

Since the HEX-L system is highly modular, you can begin with a base model and upgrade as needed. Using this method eliminates unneeded downtime and installation costs. Our systems fit a variety of research and manufacturing purposes.

THE HEX SERIES

How Do Multi-Chamber Systems Work in The Thin Film Deposition Process?

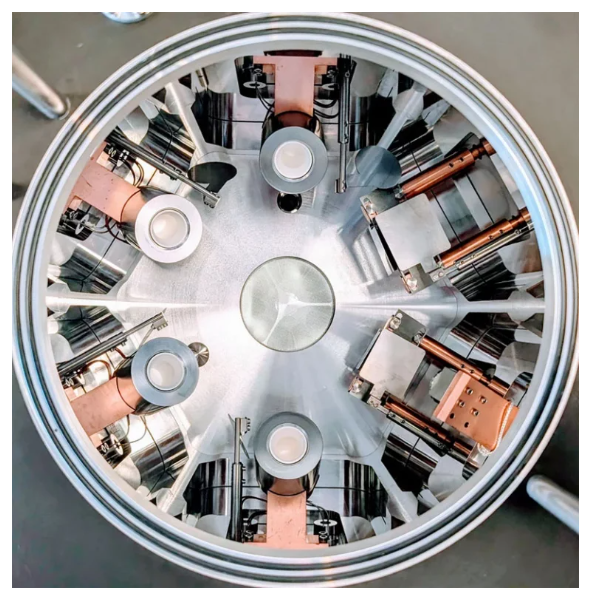

PVD cluster systems consist of three components:

- Vacuum Loadlocks

- Process Chambers

- A Central Robot

The process begins with the introduction of the substrate.

You then place a material in the vacuum to vaporise it.

With a multi-chamber system like the HEX-L, you can use various deposition techniques at once.

The thin film is then transferred onto the substrate in an even layer.

The HEX Cluster System makes the thin film deposition process more cost-efficient, timely, and effective.

Customise with Sources

We have a range of deposition sources to customise the HEX and HEX-L, depending on your required applications. If you’re unsure, please contact one of our technical specialists.

TAU | E-Beam Evaporation

The TAU E-Beam evaporation source is a ‘mini’ source, meaning that it doesn’t use the beam-bending magnets found in other, larger electron beam evaporation sources. The TAU produces a high voltage at the target material while using the low voltage at the tungsten emission filament to produce a direct heating and evaporative effect.

One of the most significant concerns with the e-beam evaporation process is the heat generated during the vaporisation stage. The TAU uses an enclosed head that reduces the thermal load in the vacuum chamber, allowing for coating at relatively low substrate temperatures. This reduced thermal energy makes the TAU a useful tool in lift-off processes and the coating of sensitive substrates.

Learn More: Electron Beam Evaporation Explained

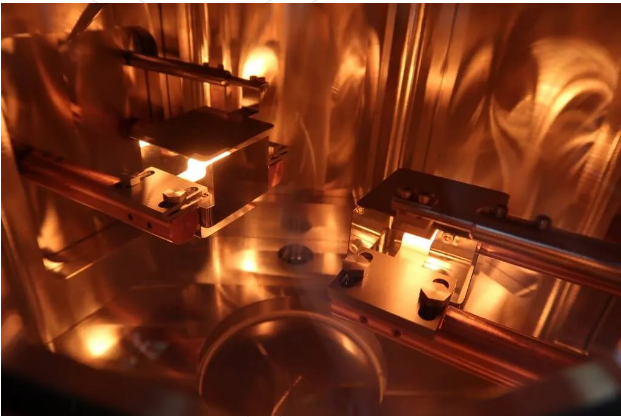

TES | Thermal Evaporation

The Korvus TES thermal boat sources allow quick removal of the sources to allow replenishment of the evaporant material. Boats and filaments can also be easily and rapidly replaced.

The TES sources are available as a single-source per flange unit. Optionally, thermocouples may be mounted to monitor the boat temperature. Each source can be equipped with a manual or automatic shutter.

Multiple sources may be accommodated in one system. The sources can also be used in conjunction with other techniques such as sputtering, e-beam deposition and low-temperature sources.

FISSION | Magnetron Sputtering

The Fission series of magnetron sputtering systems allows users to switch between thin film DC/RF sputtering without specialised tools or lengthy downtime. The Fission deposition source is a module of the modular HEX system that uses quick-release connectors for cooling and water connections, making set-up simple and fast. The HEX system provides the framework for multiple physical vapour deposition techniques, including DC/RF sputtering.

The system accommodates reactive sputtering through the introduction of the reactive gas directly into the chamber or via a separate gas feed. We recommend using the separate feed to maintain the correct partial pressure of the reactive gas at the target.

The Fission series allows the sputtering of all solid metals, magnetic materials, insulators, and semiconductors and can even process multiple sources to grow a composite thin film.

The HEX system even supports high-power impulse magnetron sputtering (HiPIMS), resulting in the target molecules arriving at the substrate as ions instead of neutral atoms. The main advantage of HiPIMS is that it allows for excellent control over the film’s microstructure, phase composition, and optical properties.

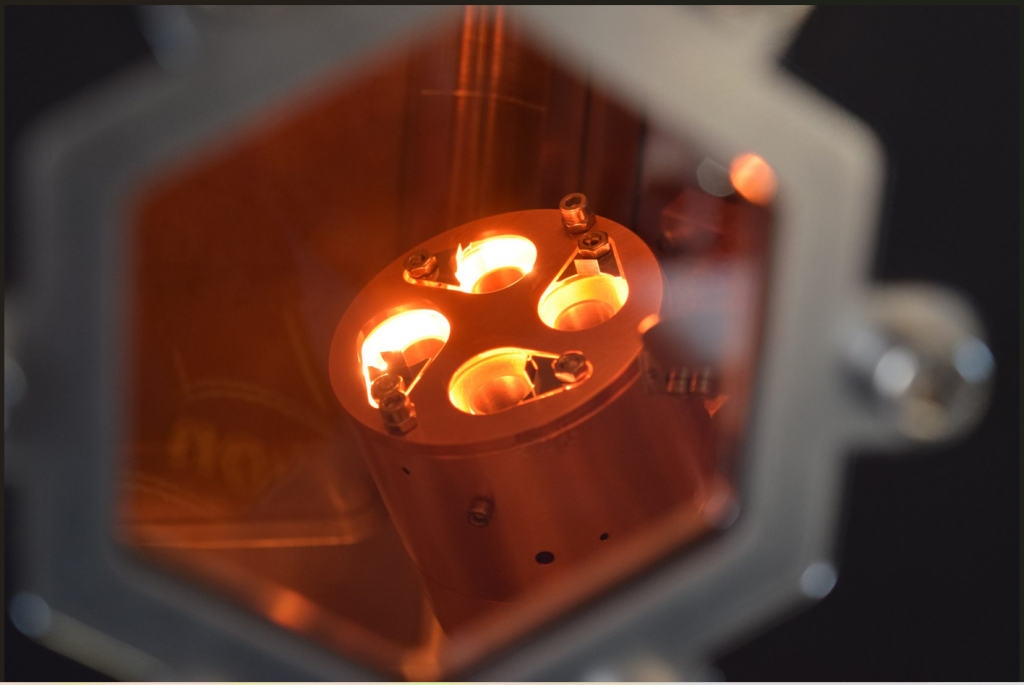

ORCA | Organic Evaporation

The ORCA low-temperature evaporation source employs active cooling of the crucible to ensure that the heating process is balanced by a strong opposing cooling process which results in excellent temperature stability and control.

The crucible is constructed from high thermal-conductivity material, ensuring no hot-spots arise which could distort the evaporation rate. Optionally, alumina or graphite liners may be employed. The crucible (complete with liner if fitted) is easily removed/swapped without the need for any tools, although this is often not necessary since access to the source in order to refill the crucible is rapid and simple.

The K-type thermocouple is inserted into the body of the crucible, giving much more accurate readings than typical touch-contact arrangements. The source is supplied with a power unit coupled with a PID controller tuned to low-temperature operation.

The source may be used in conjunction with sputter sources, e-beam sources, thermal sources and others. Thermal cross-talk is kept to a minimum through the cooled shielding cap. The ORCA is also perfectly paired with our temperature gradient sample stage allowing precise temperature control of the substrate.