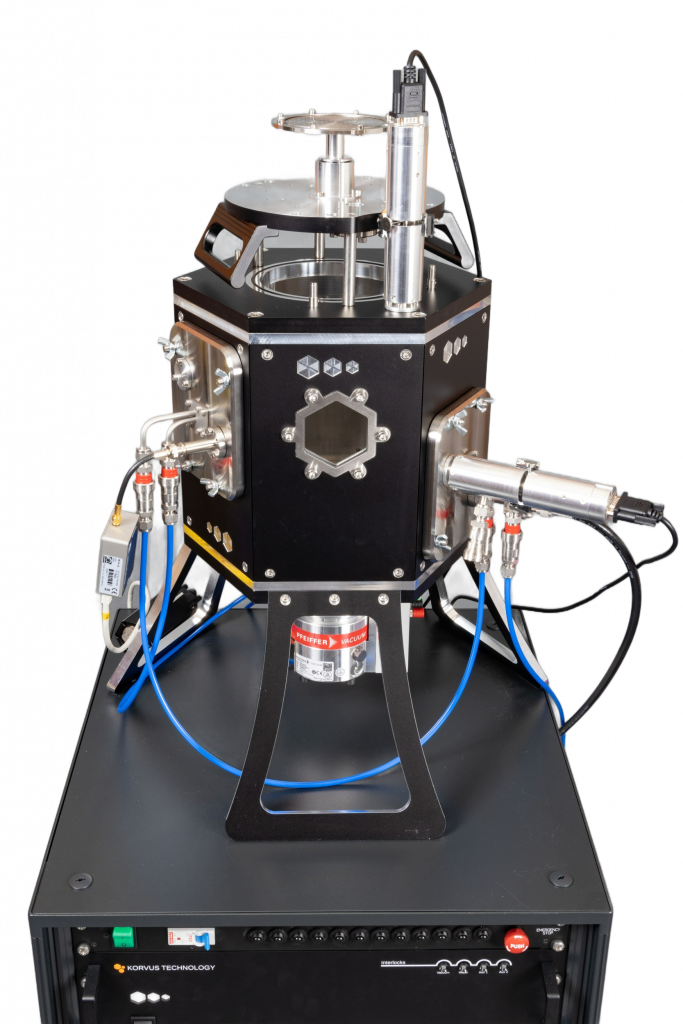

Sample Stage Options

Choosing the correct sample stage for a process is as important as choosing the correct deposition method. The features of the stage can affect the uniformity, the morphology and the resulting film composition.

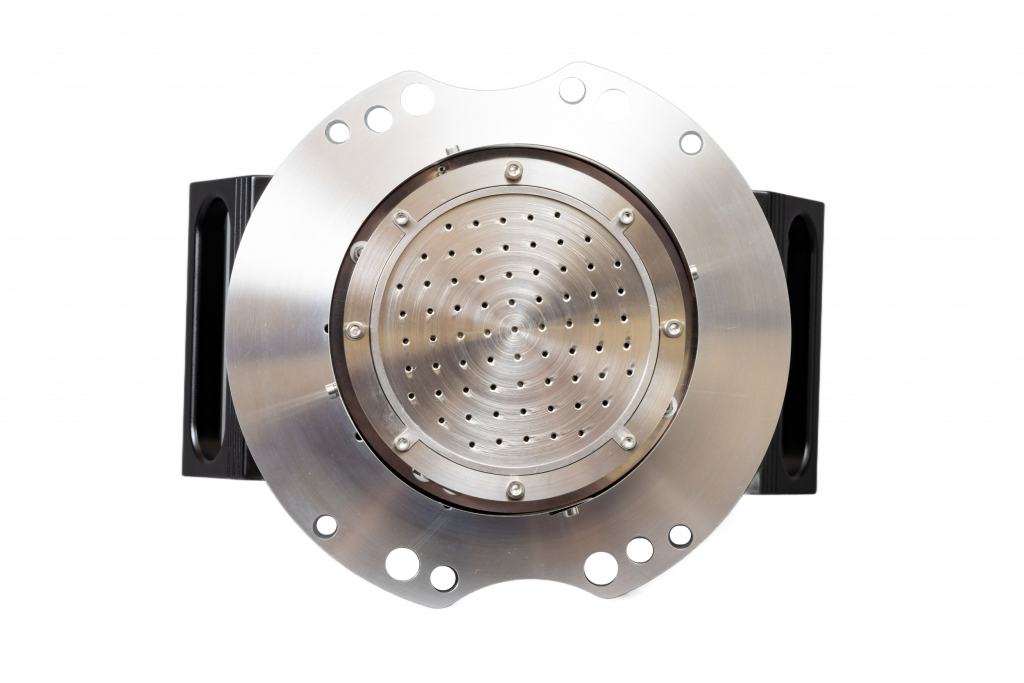

The HEX sample stage is fitted with an outer clamp ring for holding wafers, in addition to including holes for the individual clamping of smaller samples.

Sticking with the modular design philosophy of the HEX system, the sample stages are fully interchangable, so a static sample stage could easily be switched with, for example, a rotating heating bias table, with no specialist engineer assistance required.

The options available are:

- Rotation (5-28 rpm)

- Heating (up to 500℃)

- RF and DC bias

- Water Cooling (to 15℃)

- Peltier Plate Cooling (to -10℃)

Please refer to the brochure above or extra information below for more insight on our sample stages.

Rotating and Heating Stage

The stage may be upgraded to one which incorporates sample rotation and heating.

The rotation (5-28rpm as standard) improves the film uniformity dramatically and is recommended for samples with dimensions greater than 15mm and/or where good uniformity is important.

The stage has options for heating to 500℃ which will result in improved film morphology for some materials. Due to PID technology, this temperature reading is accurate to within a degree.